A kind of high strength and toughness ductile iron and preparation method thereof

A tough ball and cast iron technology, which is applied in the field of high-strength ductile cast iron and its preparation, can solve the problems that the mechanical properties of castings cannot meet the use requirements, poor mechanical properties, long production cycle, etc., and reduce the difficulty and cost of mold preparation. Method Simple and effective in reducing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

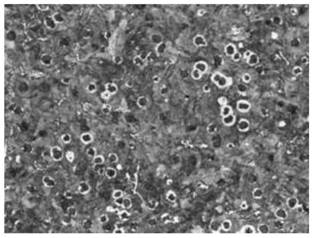

Examples

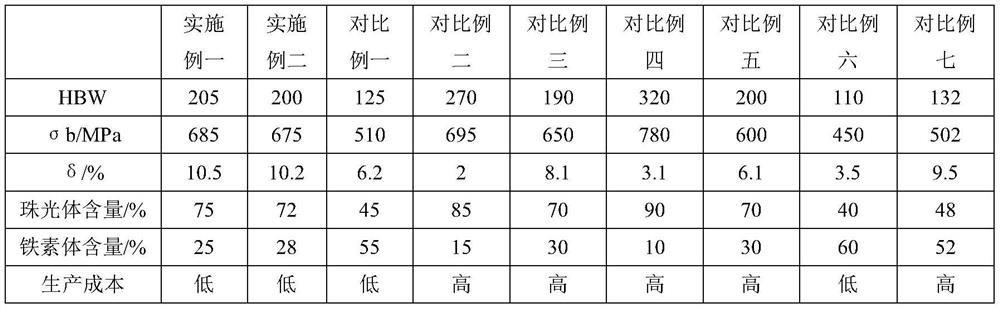

Embodiment 1

[0030] A high-strength ductile cast iron and a preparation method thereof, the steps are as follows:

[0031] (1) The raw materials are mixed according to the composition percentage. The content of C in ductile iron is 3.8%, the content of Si is 2.2%, the content of Mn is 0.9%, the content of P is 0.05%, the content of S is 0.03%, the content of Mg is 0.05%, and the balance is Fe ;

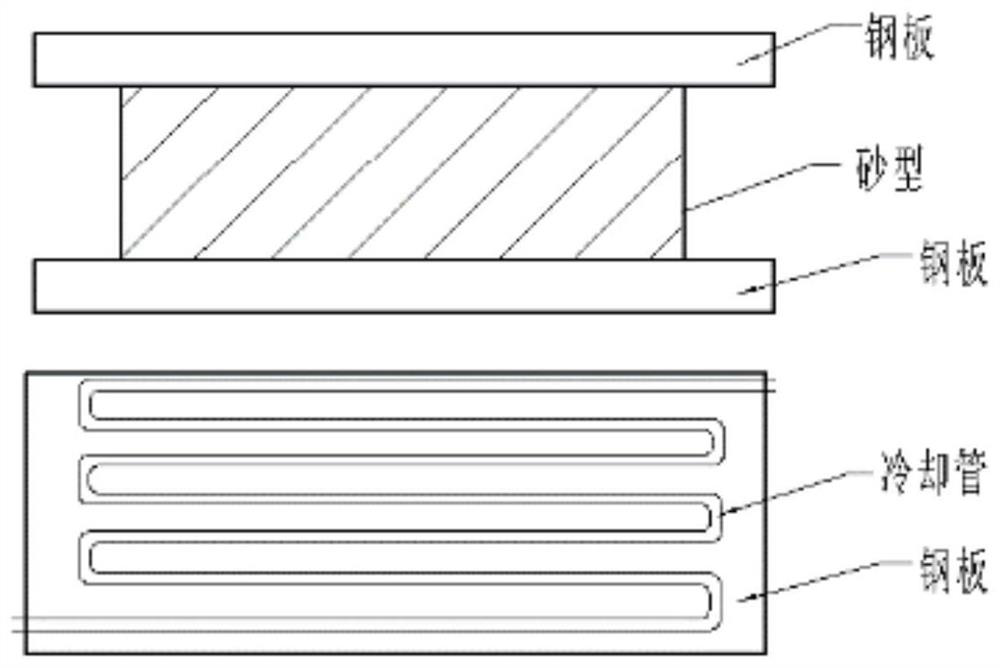

[0032] (2) Prepare the sand mold according to the size of the required workpiece, add steel plates on the upper and lower sides of the sand mold, the wall thickness of the steel plate is 30mm, and fix the cooling water pipe around the outside of the steel plate. The inner diameter of the water pipe is 10mm, and the cooling water is fed into it. ℃, using top pouring pouring system, waiting for pouring;

[0033] (3) Use an intermediate frequency induction furnace for smelting, first add pig iron for ductile iron, scrap steel and recarburizer, the smelting temperature is 1400°C, after complete melti...

Embodiment 2

[0038] A high-strength ductile cast iron and a preparation method thereof, the steps are as follows:

[0039] (1) The raw materials are mixed according to the composition percentage. The content of C in ductile iron is 3.8%, the content of Si is 2.2%, the content of Mn is 0.9%, the content of P is 0.05%, the content of S is 0.03%, the content of Mg is 0.05%, and the balance is Fe ;

[0040] (2) Prepare the sand mold according to the size of the required workpiece, add steel plates on the upper and lower sides of the sand mold, the wall thickness of the steel plate is 50mm, and fix the cooling water pipe around the outer side of the steel plate. ℃, using top pouring pouring system, waiting for pouring;

[0041] (3) Use an intermediate frequency induction furnace for smelting, first add pig iron for ductile iron, scrap steel and recarburizer, the smelting temperature is 1400°C, after complete melting, add ferromanganese and ferrosilicon, and heat up to 1500°C;

[0042](4) Pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com