A porous hollow tubular material for regeneration, repair and reconstruction of large segmental bone defects in limbs and its preparation method

A bone defect and hollow tube technology, applied in tissue regeneration, prosthesis, medical science, etc., can solve unreliable problems and achieve the effect of avoiding collapse and fast degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

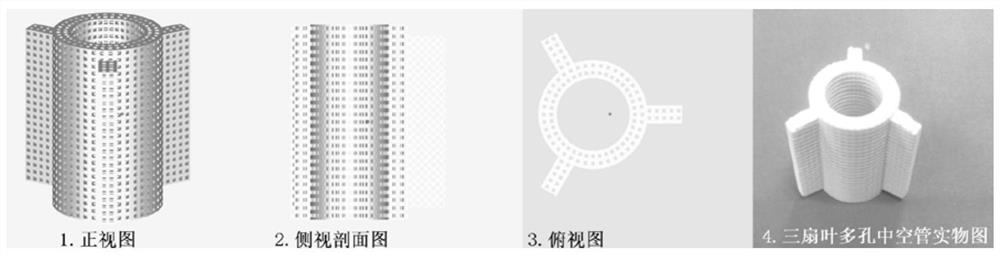

[0066] Example 1: Preparation of a porous hollow tubular material for regeneration, repair and reconstruction of large segmental bone defects of limbs with diopside ceramics as the matrix of three-blade porous hollow tubes and mesoporous bioactive glass as the channel wall coating

[0067] a) Mix 10 grams of pure diopside ultrafine powder with a particle size of 300-5000 nanometers and 6 grams of light-sensitive resin, and then pour the slurry into the slurry of digital light processing resin photo-curing ceramic 3D printer In the pool, according to the set three-dimensional shape model: the length of the tube is 80 mm, the distance between the end of the fan blade and the end of the tube is 4 mm, the inner diameter of the tube is 30 mm, the thickness of the tube wall is 12 mm, and the fan blades are parallel to each other and equidistant. The three-blade fan, the radial height of the fan blade is 8 mm, the thickness of the fan blade is 6 mm, the shape of the channel is a cube ...

Embodiment 2

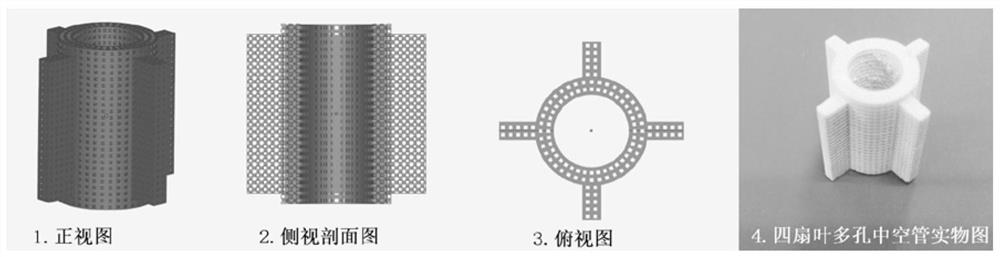

[0073] Example 2: Preparation of a porous hollow tubular material for regeneration, repair and reconstruction of large segmental bone defects of limbs with feldspar ceramic as four-blade porous hollow tube matrix and bioactive glass as pore wall coating

[0074] a) Mix 10 grams of pure yellow feldspar ultrafine powder with a particle size of 600-8000 nanometers and 7 grams of photosensitive resin evenly, and then pour the slurry into the slurry pool of the digital light processing resin photocuring ceramic three-dimensional printer. , according to the set 3D shape model: the length of the tube is 68 mm, the end of the fan blade is 3 mm away from the end of the tube, the inner diameter of the tube is 24 mm, the thickness of the tube wall is 8 mm, and the fan blades are parallel and equidistant to each other. Four fan blades, the radial height of the fan blade is 10 mm, the thickness of the fan blade is 10 mm, the shape of the channel is a cube hole, and the side length of the ch...

Embodiment 3

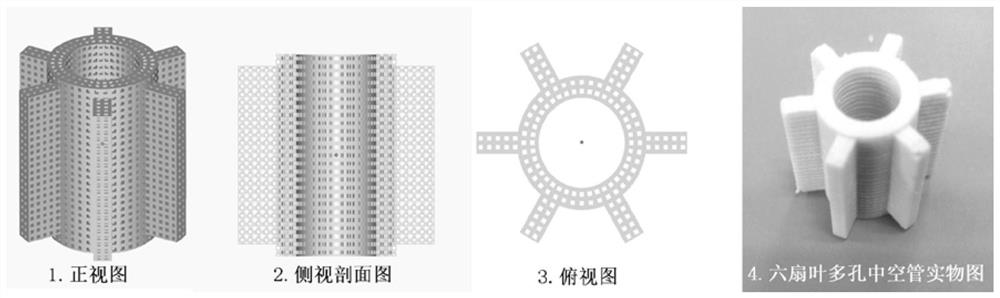

[0080] Example 3: Preparation of Mg-doped wollastonite ceramics as the matrix of the six-blade porous hollow tube and mesoporous bioactive glass as the channel wall coating for the regeneration, repair and reconstruction of large segmental bone defects in limbs

[0081] According to the similar steps for the preparation of the porous hollow tube in Example 1, diopside was replaced by magnesium-doped wollastonite in which 10% of calcium ions were replaced by magnesium, and the set three-dimensional morphological model was modified as follows: The distance from the end of the end to the end of the tube is 3 mm, the inner diameter of the tube is 25 mm, the thickness of the tube wall is 8 mm, the fan blades are six parallel and equidistant blades, the radial height of the fan blades is 8 mm, and the thickness of the fan blades is 6 mm, the channel shape is a rectangular parallelepiped hole, and the size is 650 × 650 × 500 microns; the material after ultrasonic cleaning and drying i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com