A new type of glue-coated filter cloth and its production process

A production process and filter cloth technology, applied in the field of new rubberized filter cloth and its production process, can solve problems such as poor sealing of filter cloth, and achieve the effect of high repeated use rate, solving leakage problem and high flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Glue production process:

[0032] Mix 1kg of nitrile rubber, 2kg of butadiene rubber, 32g of sulfur accelerator, 51g of tackifier and 65g of filler rubber and auxiliary agents through a rubber mixer to prepare a mortar masterbatch; put the above glue in a glass container Dissolve the slurry masterbatch into 8L of cyclohexanone and n-butanol mixed solvent (the volume ratio of cyclohexanone and n-butanol is 1:1), and store it in a sealed place, and store it for 3 days for later use, during which period it is stirred periodically every 2 hours Once, the stirring speed is controlled at about 50r / min;

[0033] Second, the filter cloth treatment process:

[0034] 1) Pre-treat the filter cloth to ensure that the filter cloth is dry and clean;

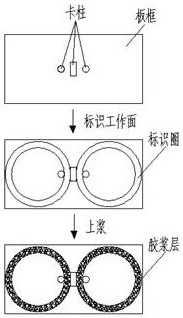

[0035] 2) Mark the working ring surface;

[0036] 3) Evenly sprinkle the glue obtained in step 1 on the marking area;

[0037] 4) Put the filter cloth in a constant temperature environment, use a vulcanizing agent aqueous solutio...

Embodiment 2

[0038] Embodiment 2: Take the same mortar formula as in Example 1, and the steps of filter cloth sizing are also exactly the same as in Example 1. The only difference is that the novel vulcanization process proposed by the present invention is adopted, and the specific vulcanization process is operated as follows:

[0039] 1) Use hydrogen sulfide generator to take over to seal and fumigate the filter cloth sprinkled with glue, control the gas temperature in the fumigation room to be 63°C, and fumigate for 3 minutes;

[0040] 2) Take out the fumigated filter cloth, spray 25% hydrogen peroxide aqueous solution, and react for 5 minutes at room temperature;

[0041] 3) Heat and vulcanize the reacted filter cloth with steam in a sealed container, raise the temperature to 130°C, and vulcanize for 2 hours;

[0042] 4) Use 5%-10% sodium hydroxide aqueous solution to wash the vulcanized filter cloth for 2-3 times, then wash it with pure water for 2-3 times, and finally use 65°C and 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com