Waste lithium battery pyrolysis recycling method

A recycling method, lithium battery technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of high cost of acid and organic solvent treatment, higher requirements for pretreatment and separation, and low safety factor of operating environment , to achieve the effect of reducing the multi-stage crushing process, avoiding the danger of discharge and fire, and avoiding emission pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

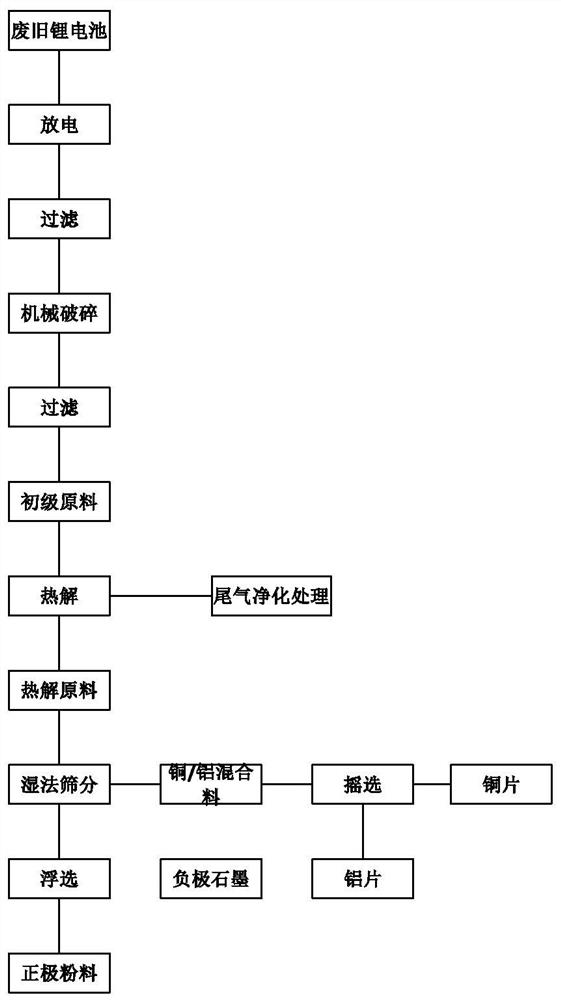

[0030] This embodiment according to figure 1 The process flow chart of the waste lithium battery pyrolysis recovery method shown is a detailed description of the waste lithium battery pyrolysis recovery process of the present invention by taking the waste lithium battery recovery process as an example.

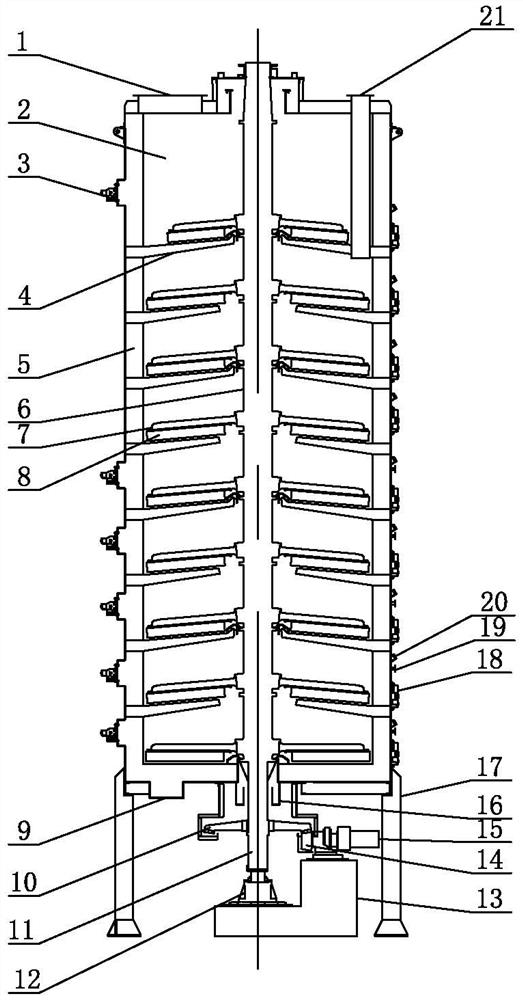

[0031] Firstly, the multi-stage furnace with an integrated post-combustion chamber used in the pyrolysis process of this embodiment is described, such as figure 2 As shown, including the furnace body 5, several layers of hearths are arranged at intervals in the vertical direction in the furnace body 5, and a number of burners 3 are arranged in the circumferential direction of the furnace body wall between each layer of hearths, and each burner 3 is respectively equipped with a flow rate The valve controls the gas inlet and air inlet. According to the temperature control requirements of pyrolysis, multiple burners 3 can be installed on the circumferential furnace wall above ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com