Environment-friendly silver-loaded antibacterial agent based on plant waste powder and preparation method of environment-friendly silver-loaded antibacterial agent

A technology of plant waste and antibacterial agent, which is applied in the field of environment-friendly silver-loaded antibacterial agent and its preparation, can solve the problems of weak interaction between nano-silver and substrate, high risk of environmental pollution, complex process and reagents, etc. The effect of low cost and uniform load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

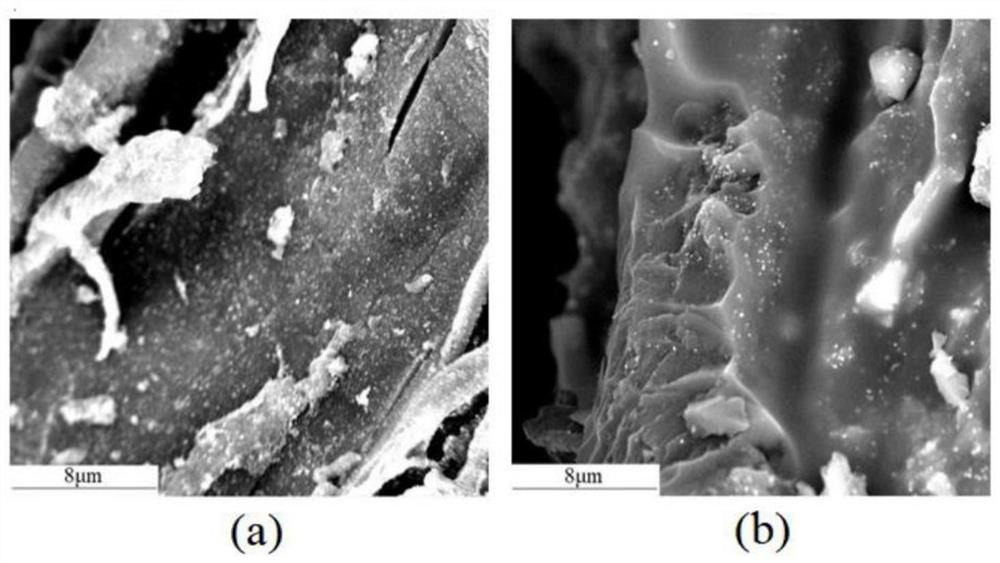

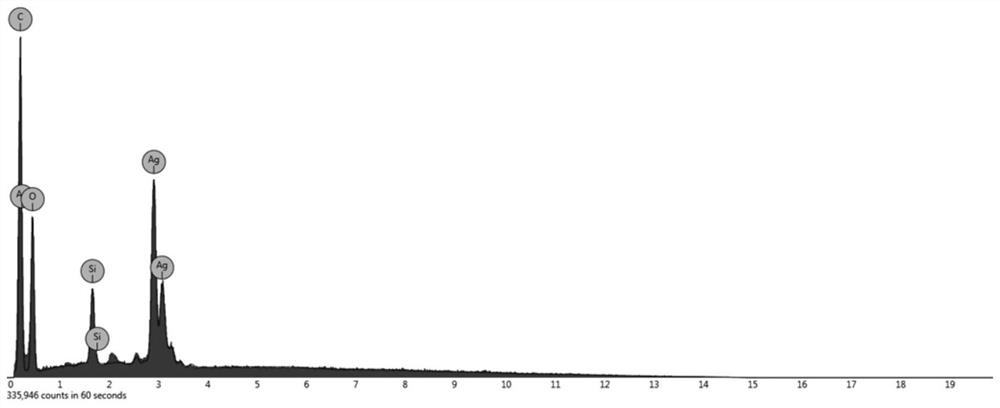

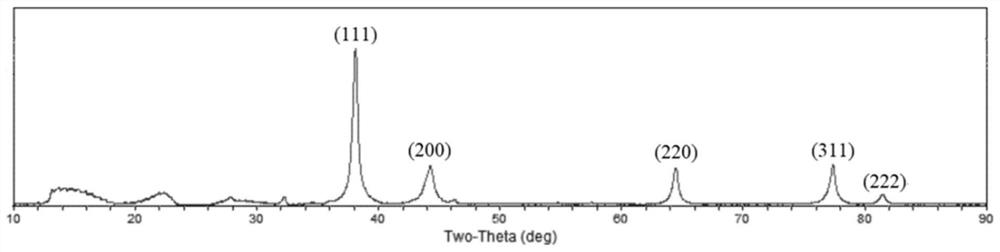

[0034] Plant waste (bamboo wood) was pulverized and ground into powder to obtain 200-mesh plant waste powder. In parts by weight, 27 parts of silver nitrate were dissolved in water, followed by adding 63 parts of plant waste powder (bamboo wood powder) and 10 parts of γ-aminopropyltriethoxysilane, and after uniform stirring, absorb in the dark for 100 minutes. Then place it in a 90°C oven and dry it for 24h to obtain a silver-loaded antibacterial agent based on plant waste powder, as shown in the scanning electron micrograph figure 1 As shown in b, the EDS spectrum is as figure 2 As shown, the XRD pattern is as image 3 shown. The results show that the nano-silver is uniformly dispersed on the plant waste powder, the average particle size of the nano-silver is about 14.0nm, and the interface between the nano-silver and the substrate is fuzzy, and the interaction between the two is strong. The antibacterial rates of the prepared silver-loaded antibacterial agent against Esc...

Embodiment 2

[0036] The plant waste (coconut husk) was pulverized and ground into powder to obtain a 100-mesh plant waste powder. In parts by weight, dissolve 5 parts of silver acetate in water, add 90 parts of plant waste powder (coconut shell powder) and 5 parts of γ-glycidyl ether oxypropyltrimethoxysilane in turn, stir evenly and avoid light for adsorption 10 min, and then placed in an oven at 60° C. for 36 h to obtain a silver-loaded antibacterial agent based on plant waste powder, whose scanning electron microscope pattern, EDS pattern and XRD pattern are similar to those of Example 1.

[0037] After testing, the nano-silver is uniformly dispersed on the plant waste powder, and the average particle size of the nano-silver is about 16.8nm. The antibacterial rates of the prepared silver-loaded antibacterial agent against Escherichia coli and Staphylococcus aureus were 97% and 94% respectively (the antibacterial performance test standard is GB / T 21510-2008).

Embodiment 3

[0039] The plant waste (wheat straw) was pulverized and ground into powder to obtain a 40-mesh plant waste powder. In parts by weight, 37 parts of silver nitrate and 3 parts of silver acetate were dissolved in water, followed by adding 59 parts of plant waste powder (wheat straw powder) and 1 part of γ-methacryloxypropyltrimethoxysilane , after uniform stirring, absorb in the dark for 200min, and then place it in a 120°C oven and dry for 10h to obtain a silver-loaded antibacterial agent based on plant waste powder. The scanning electron microscope, EDS and XRD patterns are similar to those in Example 1.

[0040] After testing, the nano-silver is uniformly dispersed on the plant waste powder, and the average particle diameter of the nano-silver is about 18.3nm. The antibacterial rate of the obtained antibacterial agent against Escherichia coli and Staphylococcus aureus is 100% (the antibacterial performance test standard is GB / T21510-2008).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com