Lignin/nanocellulose-based carbon fiber and preparation method thereof

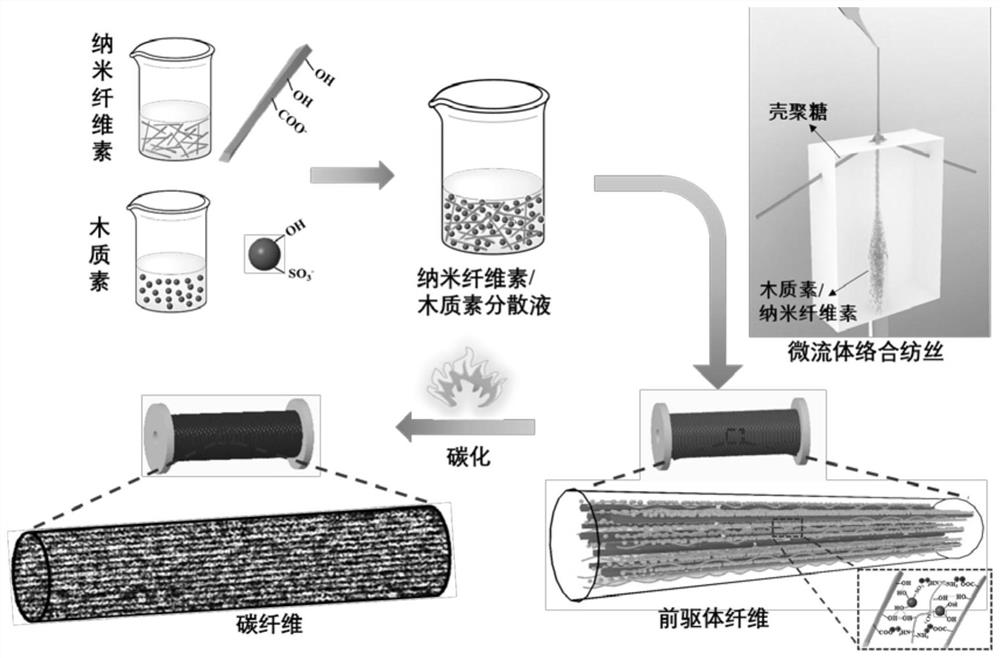

A nanocellulose, carbon fiber-based technology, applied in spinning solution preparation, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of weak tensile and shear flow fields, poor mechanical properties of carbon fibers, etc., and achieve perfect crystallization, High degree of carbon crystal orientation and the effect of solving structural irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of nanocellulose

[0036] Disperse 10g of bleached jute fiber in 960ml of water, and keep stirring, then add 0.3g of NaBr and 0.06g of TEMPO, keep stirring until completely dissolved, finally, add 39g of NaClO aqueous solution, the TEMPO oxidation reaction of cellulose begins, keep stirring during the reaction And monitor the pH value of the reaction system with a pH meter. As the reaction progresses, the pH value of the system continues to drop, and the pH value of the reaction system is kept between 10-10.3 by continuously adding 1mol / L NaOH aqueous solution dropwise. The entire reaction lasts for 24 hours to complete the reaction completely, and then add 2 ml Absolute ethanol was used to terminate the reaction, and the whole reaction was carried out at room temperature. Then it was washed to neutrality by centrifugation, and finally homogenized with a homogenizer at 800W to obtain a cellulose nanofiber hydrogel, which was diluted with deionized water...

Embodiment 2

[0048] In the lignin / nanocellulose spinning solution prepared in step (3), the proportion of lignin was 50 wt%, and the rest of the steps were the same as in Example 1.

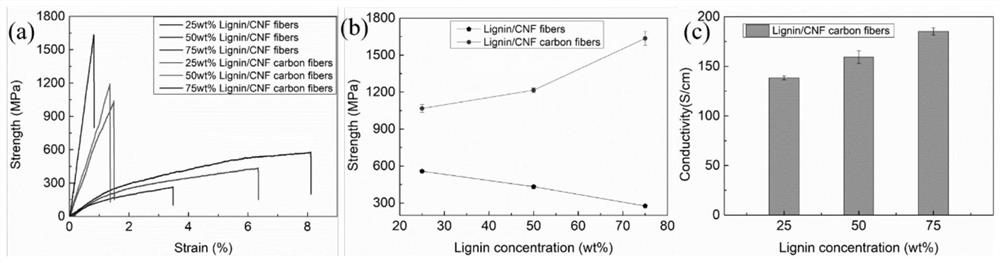

[0049] The tensile strength of the carbon fiber precursor prepared in this example is 431.89±12.56MPa, the tensile strength of the prepared carbon fiber is 1214.93±19.43MPa, and the electrical conductivity is 159.3±6.53 S / cm.

Embodiment 3

[0051] In the lignin / nanocellulose spinning solution prepared in step (3), the proportion of lignin is 75wt%, and the rest of the steps are the same as in Example 1.

[0052] The tensile strength of the carbon fiber precursor prepared in this example is 276.01±6.25 MPa, the tensile strength of the prepared carbon fiber is 1635±56.7 MPa, and the electrical conductivity is 185.33±3.62 S / cm.

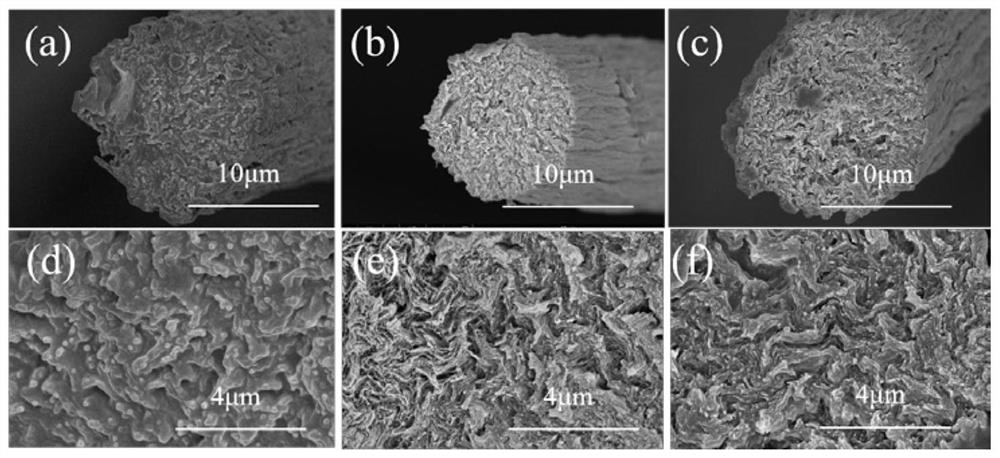

[0053] It can be seen from Examples 1-3 that during the spinning process, lignin / nanocellulose is highly oriented and assembled under the action of the tensile force field in the converging flow channel, and the positively charged chitosan and negatively charged lignin / nanocellulose The ionic crosslinking of cellulose fixes the orientation structure of fibers, such as figure 2 It is shown that the tensile strength of carbon fiber precursors decreases gradually with the increase of lignin content. When the lignin content was 75 wt%, the tensile strength of the prepared carbon fiber precurs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com