A kind of sulfone-containing polysiloxane fiber and its preparation method

A polysiloxane and polysiloxane spinning technology, which is applied in the field of synthetic fibers, can solve the problems that polysiloxane is difficult to spin, difficult to spin, and polysiloxane fibers cannot be recycled, so as to improve crystallization Properties and intermolecular interactions, easy spinning, simple and efficient synthesis route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Add 8.6g (50mmol) of α,α'-dimercapto-p-xylene, 9.2g (50mmol) of vinyl double caps, and 0.2g of benzoin dimethyl ether (DMPA) into a round bottom flask. After sealing, it was placed under a UV lamp and stirred for 15 minutes, the system became viscous, and the crude product was obtained as a yellow viscous liquid. After vacuum drying, a light yellow transparent viscous was obtained with a yield of 16.3 g and a yield of 92%. Weigh 16.3 g (46 mmol) of the above viscous liquid and dissolve it in a flask with tetrahydrofuran. After that, 14.1 g (46 mmol) of the oxidizing agent oxone was added, and under the protection of nitrogen, the reaction was stirred at room temperature for 12 hours. Then 14.1 g (46 mmol) of oxone was added to the system, and the reaction was continued for 12 hours with stirring at room temperature. After the reaction was completed, white flaky crystals of P1OX were obtained, with a yield of 8.3 g and a yield of 55%.

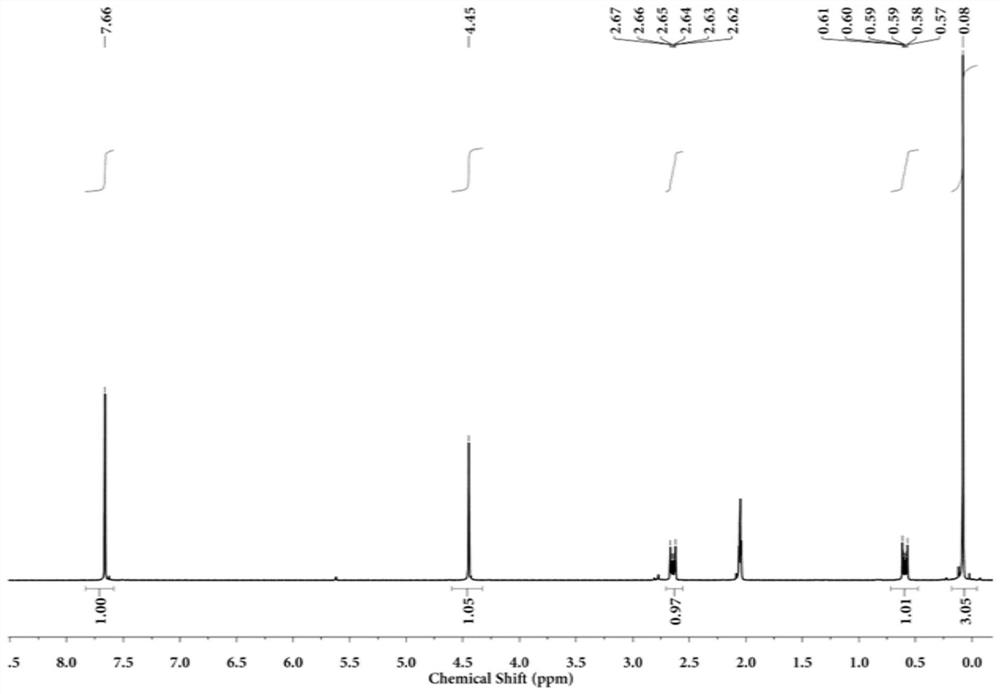

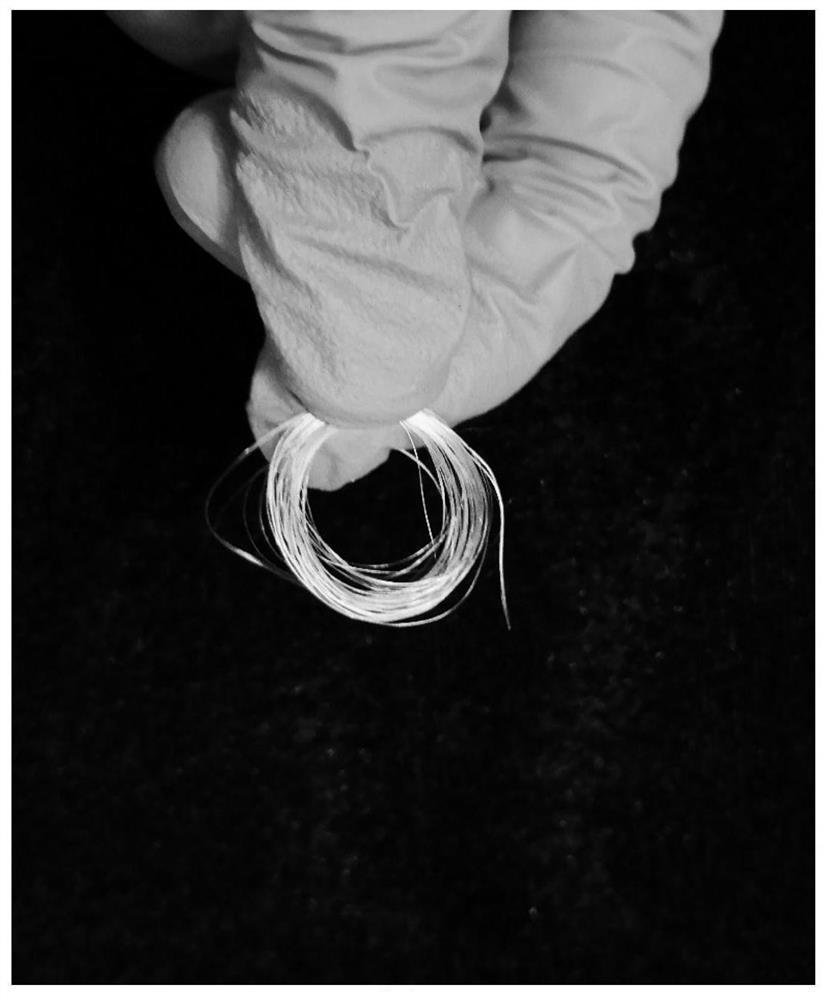

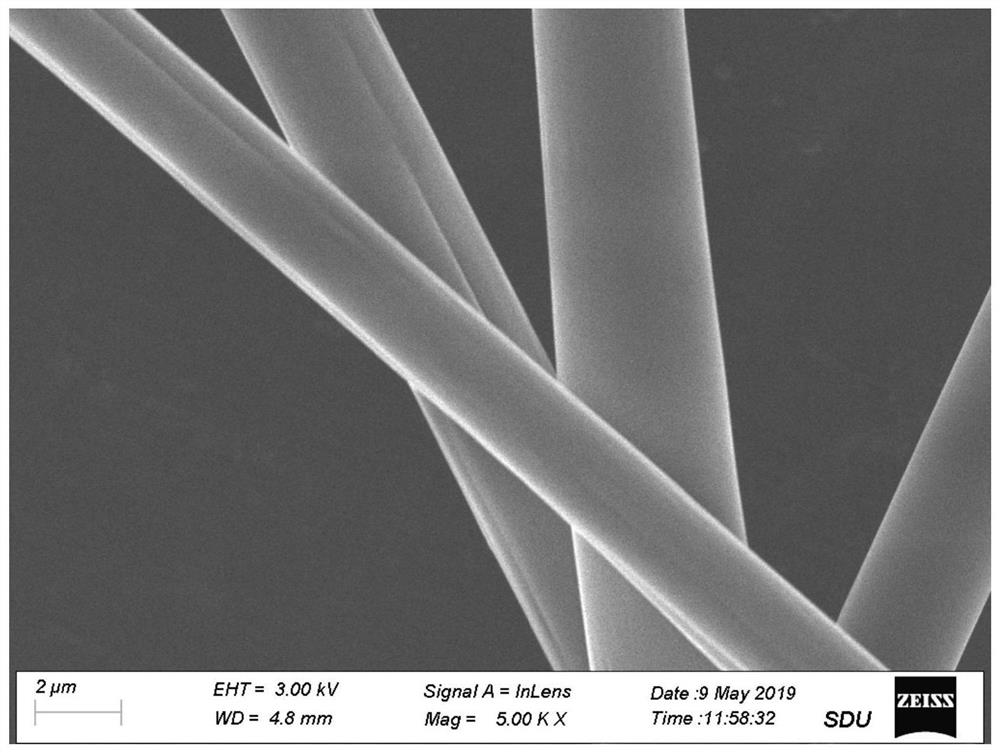

[0059] The product was test...

Embodiment 2

[0065] (1) Add 6.1 g (50 mmol) of butanedithiol, 9.2 g (50 mmol) of vinyl double caps, and 0.2 g of benzoin dicarboxylic acid (DMPA) into a round bottom flask. After sealing, it was placed under a UV lamp and stirred for 15 minutes. The system became viscous, and the crude product was obtained as a colorless viscous liquid. After vacuum drying, a light yellow transparent viscous was obtained with a yield of 14.3 g and a yield of 94%. Weigh 14.1 g (46 mmol) of the above viscous liquid and dissolve it in a flask with tetrahydrofuran. After that, 14.1 g (46 mmol) of the oxidizing agent oxone was added, and under the protection of nitrogen, the reaction was stirred at room temperature for 12 hours. Then 14.1 g (46 mmol) of oxone was added to the system, and the reaction was continued for 12 h with stirring at room temperature. After the reaction was completed, white flaky crystals of P2OX were obtained with a yield of 51%.

[0066] (2) Dissolve the sulfone-containing macrocycli...

Embodiment 3

[0069] (1) Add 12.5g (50mmol) of 4'4-dimercaptodiphenylsulfide, 9.2g (50mmol) of vinyl double caps, and 0.2g of benzoin dicarboxylic acid (DMPA) into a round bottom flask. After sealing, it was placed under a UV lamp and stirred for 15 minutes, the system became viscous, and the crude product was obtained as a yellow viscous liquid. After vacuum drying, a light yellow transparent viscous was obtained with a yield of 19.5 g and a yield of 91%. Weigh 20.0 g (46 mmol) of the above viscous liquid and dissolve it in a flask with tetrahydrofuran. Afterwards, 21.1 g (69 mmol) of the oxidant oxone was added, and under the protection of nitrogen, the reaction was stirred at room temperature for 12 hours. Then 21.1 g (69 mmol) of oxone was added to the system, and the reaction was continued for 12 h with stirring at room temperature. After the reaction was completed, white flaky crystals were obtained with a yield of 55%.

[0070] (2) Dissolve the sulfone-containing macrocyclic silox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com