FeCoNiCrMnAl high-entropy alloy electrolytic corrosion electrolyte and metallographic structure display method thereof

A metallographic structure display, high-entropy alloy technology, applied in the field of high-entropy alloys, can solve the problem of poor effect of ordinary aqua regia, achieve good grain boundary corrosion effect, high-efficiency and short-time realization, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The invention provides an electrolyte solution for electrolytic corrosion of a FeCoNiCrMnAl high-entropy alloy, wherein the electrolyte solution is a perchloric acid ethanol solution with a mass fraction of 10%.

[0038] The invention provides a method for displaying the metallographic structure of a FeCoNiCrMnAl high-entropy alloy, comprising the following steps:

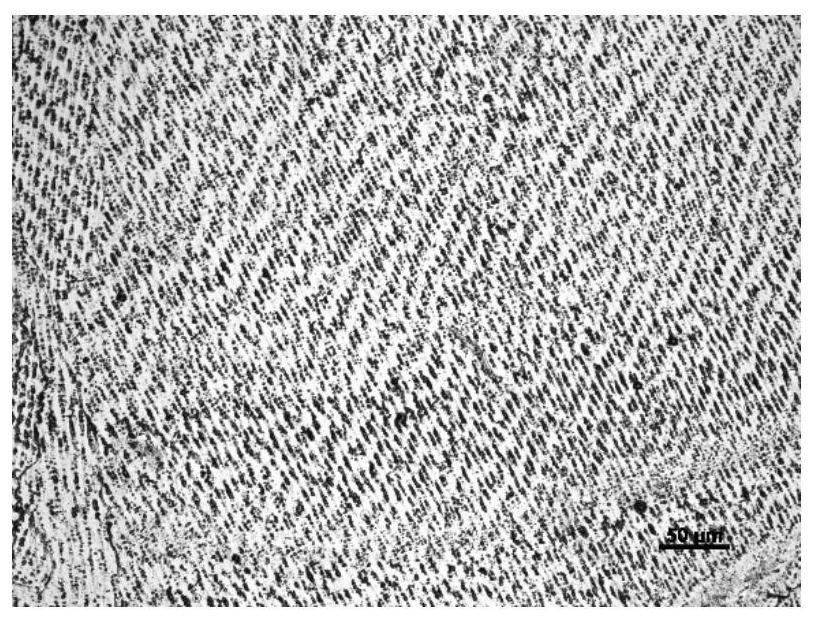

[0039] Firstly grind the metallographic sample roughly on 150# sandpaper, then use 200#, 400#, 600#, 800#, 1000#, 1200#, 1500# sandpaper for fine grinding, and use the same sandpaper as the previous one for the next sandpaper The direction of sandpaper grinding is perpendicular to the direction, use 150# sandpaper for rough grinding 50 times, use 200#, 400#, 600#, 800#, 1000#, 1200#, 1500# for fine grinding, each fine grinding 50 Down. Polishing agent use specification is that the synthetic diamond abrasive paste of W1.5 is polished, and polishing cloth material is woolen cloth, and lubricant is distilled w...

Embodiment 2

[0041] The invention provides an electrolyte solution for electrolytic corrosion of a FeCoNiCrMnAl high-entropy alloy, wherein the electrolyte solution is a perchloric acid ethanol solution with a mass fraction of 20%.

[0042] The invention provides a method for displaying the metallographic structure of a FeCoNiCrMnAl high-entropy alloy, comprising the following steps:

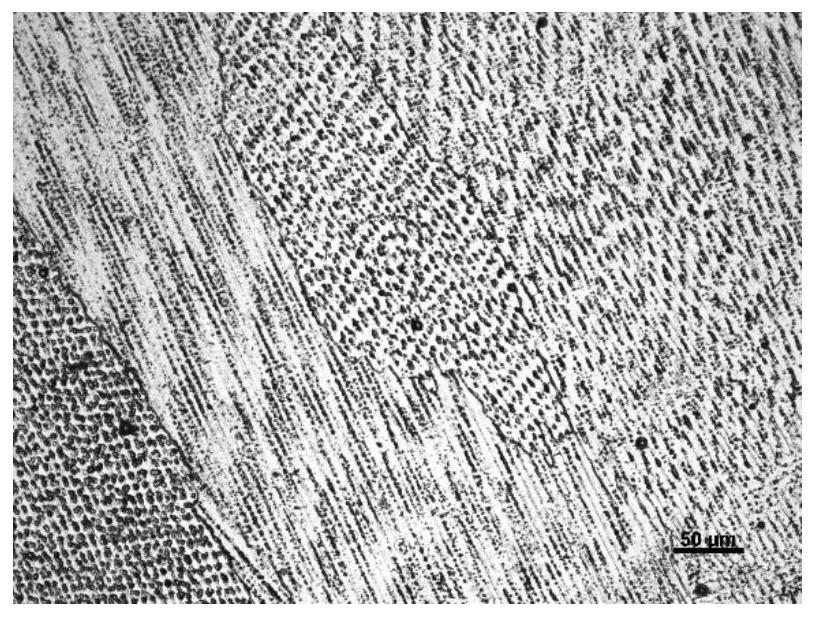

[0043] Firstly grind the metallographic sample roughly on 150# sandpaper, then use 200#, 400#, 600#, 800#, 1000#, 1200#, 1500# sandpaper for fine grinding, and use the same sandpaper as the previous one for the next sandpaper The direction of sandpaper grinding is perpendicular to the direction, use 150# sandpaper for rough grinding 50 times, use 200#, 400#, 600#, 800#, 1000#, 1200#, 1500# sandpaper for fine grinding, 50 times for each fine grinding . The polishing agent is polished with the synthetic diamond abrasive paste of W1.5, the polishing cloth material is woolen cloth, the lubricant is distilled wa...

Embodiment 3

[0045]The invention provides an electrolytic solution for electrolytic corrosion of FeCoNiCrMnAl high-entropy alloy. The electrolytic solution is a perchloric acid ethanol solution with a mass fraction of 15%.

[0046] The invention provides a method for displaying the metallographic structure of a FeCoNiCrMnAl high-entropy alloy, comprising the following steps:

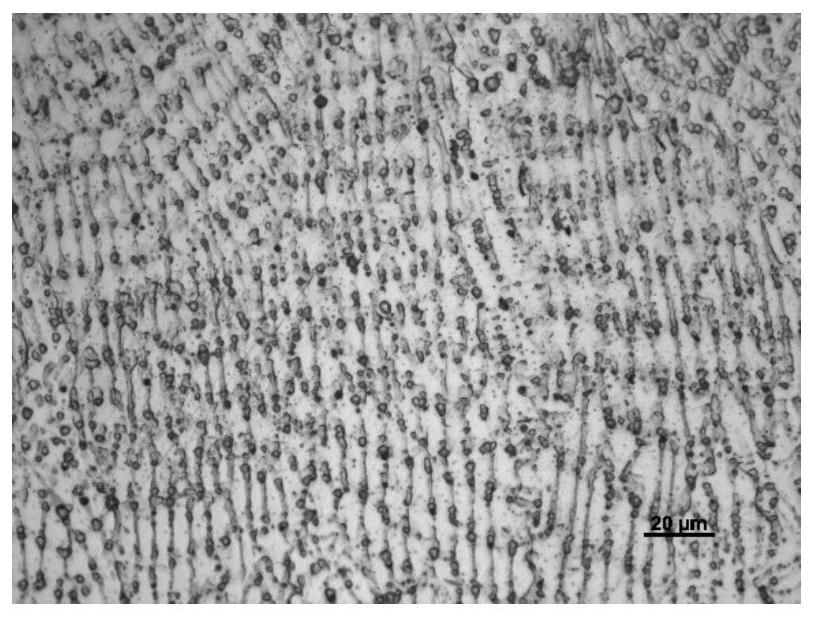

[0047] Firstly grind the metallographic sample roughly on 150# sandpaper, then use 200#, 400#, 600#, 800#, 1000#, 1200#, 1500# sandpaper for fine grinding, and use the same sandpaper as the previous one for the next sandpaper The direction of sandpaper grinding is perpendicular to the direction, use 150# sandpaper for rough grinding 50 times, use 200#, 400#, 600#, 800#, 1000#, 1200#, 1500# for fine grinding, each fine grinding 50 Down. The polishing agent uses the synthetic diamond abrasive paste of W1.5 to polish, the polishing cloth material is woolen cloth, the lubricant is distilled water, the polishing disc rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com