Preparation method and application of lentinus edodes mycelium bio-based composite material

A composite material and bio-based technology, which is applied in the field of preparation of mushroom mycelium bio-based composite materials, can solve the problems of not being able to obtain large-scale applications, and achieve good heat insulation effect, realization of utilization, and hard material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

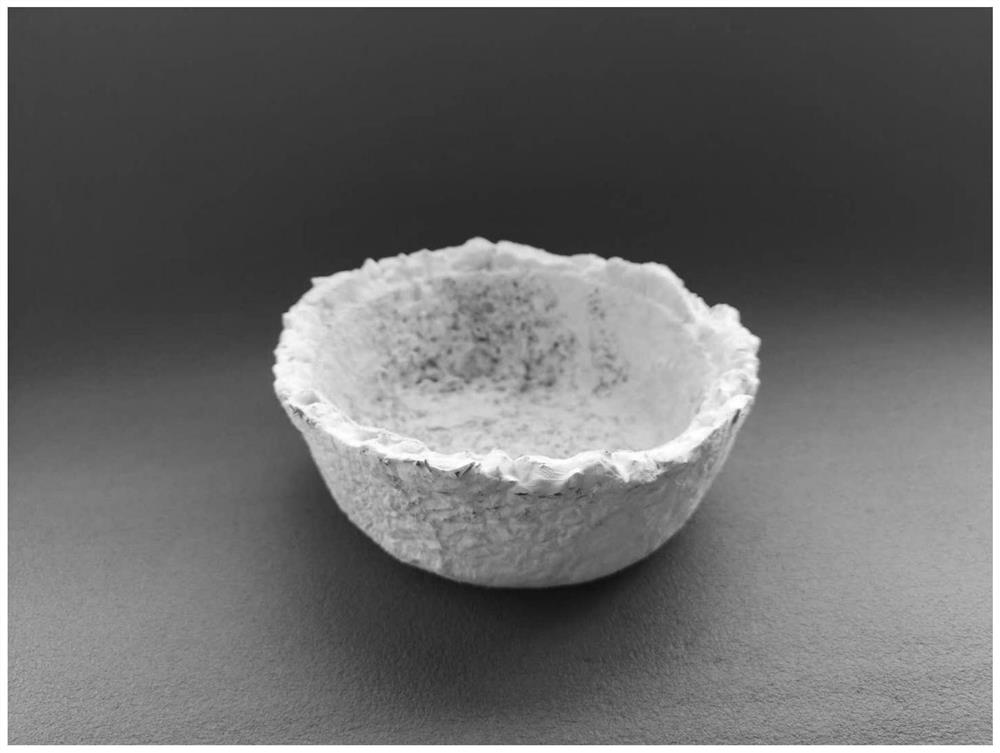

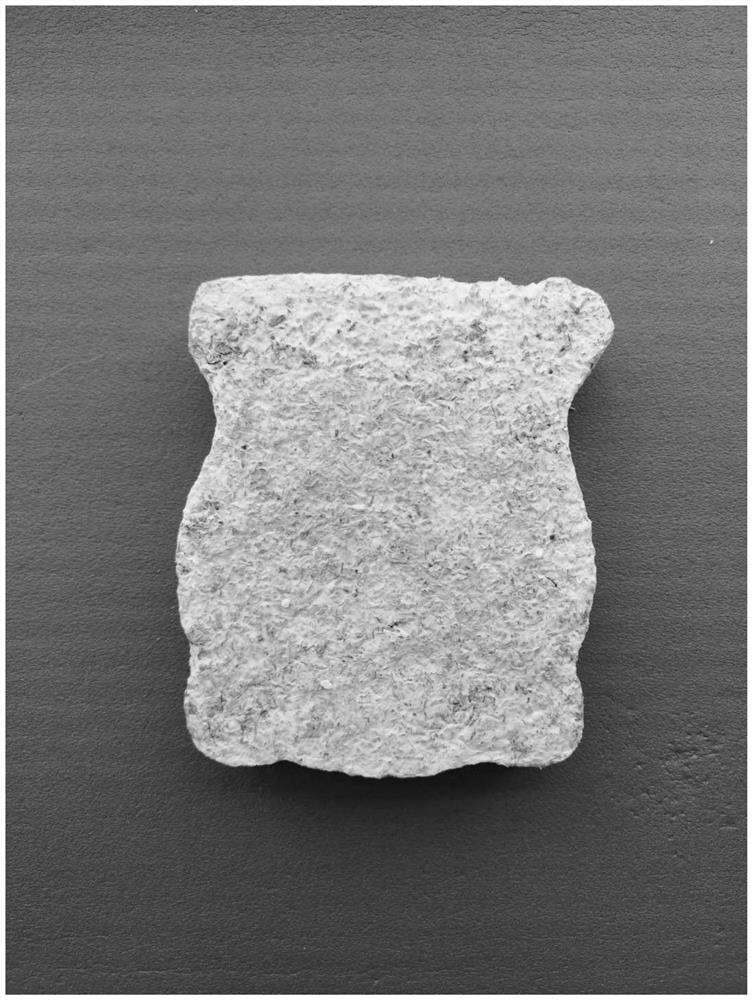

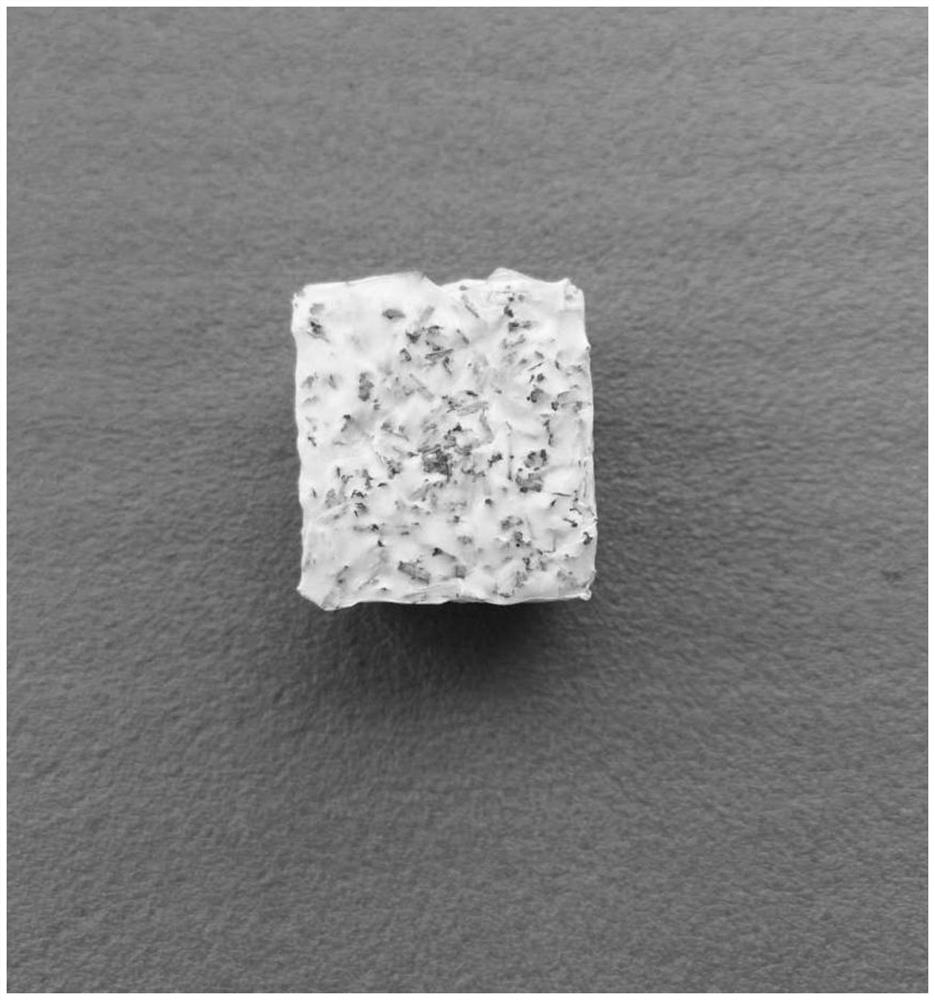

Image

Examples

Embodiment 1

[0056] The preparation method of mushroom mycelium bio-based composite material in this embodiment is as follows:

[0057] (1) Sawdust is crushed in advance to a particle size range of 3-6mm and an average particle size of 4.6mm, corn cobs are crushed to a particle size range of 1-3mm and an average particle size of 2.2mm, and wheat bran is crushed to a particle size The range is 40-60μm, the average particle size is 51μm, and then according to the mass percentage, mix 78% wood chips, 5% corncobs, 15% wheat bran, 1% gypsum, 1% lime, adjust the water content to 56%, and then pack bags, sterilized by high-pressure steam at 121°C and 0.15kpa pressure for 25 minutes to make biological culture medium;

[0058] (2) Inoculate the mushroom strain into the biological culture medium on the aseptic operation table, and carry out the first hyphae culture, that is, cultivate for 45 days at a constant temperature of 25°C, in the dark, and with an oxygen content of 20%;

[0059] (3) The pro...

Embodiment 2

[0062] The preparation method of mushroom mycelium bio-based composite material in this embodiment is as follows:

[0063] (1) Sawdust is crushed in advance to a particle size range of 3-6mm and an average particle size of 4.6mm, cottonseed hulls are crushed to a particle size range of 1-3mm and an average particle size of 2.2mm, and wheat bran is crushed to a particle size The size range is 40-60μm, the average particle size is 51μm, and then according to the mass percentage, mix 69% wood chips, 12% cotton seed hulls, 14% wheat bran, 1% gypsum, 1% lime, and 3% hemp grass to adjust the water content to 55%, then bagged, and sterilized by high-pressure steam at 121°C and 0.15kpa pressure for 25 minutes to make a biological medium;

[0064] (2) Inoculate the shiitake mushroom strain into the biological culture medium on the aseptic operation table, and carry out the first hyphae culture, that is, cultivate for 49 days at a constant temperature of 23°C, in the dark, and with an o...

Embodiment 3

[0068] The preparation method of mushroom mycelium bio-based composite material in this embodiment is as follows:

[0069] (1) Sawdust is crushed in advance to a particle size range of 3-6mm and an average particle size of 4.6mm, cottonseed hulls are crushed to a particle size range of 1-3mm and an average particle size of 2.2mm, and wheat bran is crushed to a particle size The size range is 40-60 μm, and the average particle size is 51 μm. According to the mass percentage, prepare 72% sawdust, 5% straw, 5% bagasse, 14% wheat bran, 2% gauze, 1% gypsum, and 1% lime. Mix sawdust, straw, bagasse, wheat bran, gypsum, and lime, adjust the water content to 57%, then pack into bags and sterilize under high-pressure steam at 121°C and 0.15kpa pressure for 25 minutes to make a biological medium;

[0070] (2) Inoculate the shiitake mushroom strain into the biological culture medium on the aseptic operation table, and carry out the first hyphae culture, that is, cultivate for 46 days at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com