Adsorption film for biofilm DGT device, preparation method and application

A biofilm and adsorption film technology, applied in the field of environmental science, can solve the problems of increased sensitivity, high input cost, and reduced cost, and achieve the effects of accurate and effective monitoring, sensitive detection, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

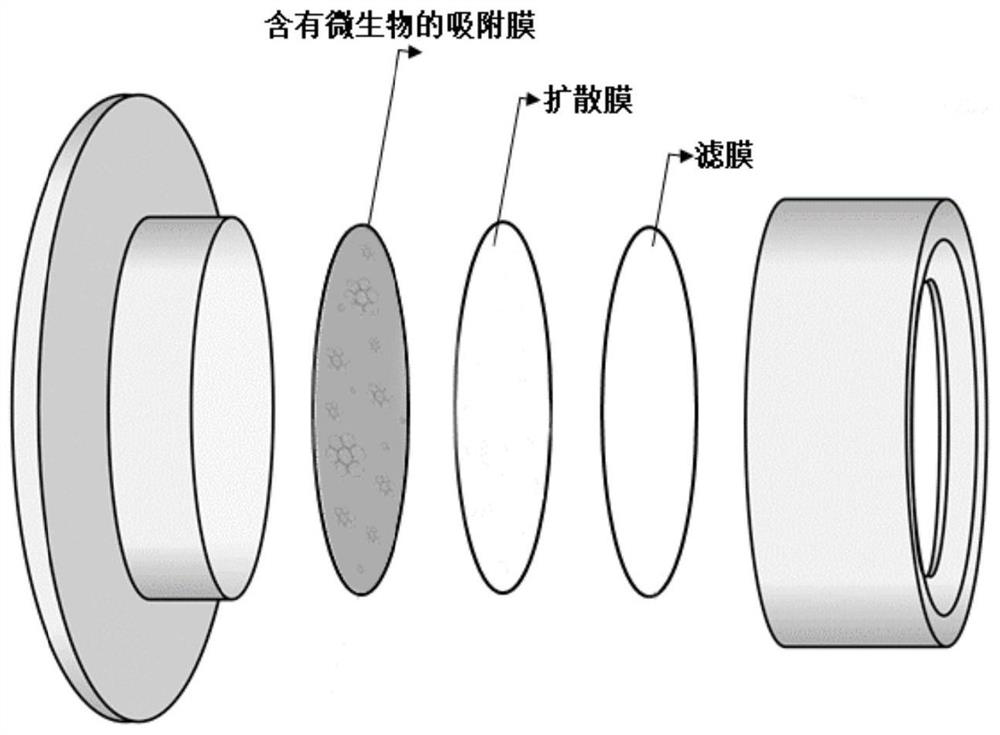

[0053] This example is the preparation of the sensory microbial adsorption film, the assembly and sampling of the biofilm DGT device.

[0054] The preparation method of the sensory state microbial adsorption film comprises the following steps:

[0055] 1) First prepare a suspension containing the sensory microorganism ADPWH_recA: the luxCDABE gene is fused into the chromosome of the Acinetobacter baylyi ADP1 host cell to construct;

[0056] 2) The constructed sensory microorganisms were first cultured at a constant temperature (30°C) for 16 hours in a medium (Luria-Bertani, LB) supplemented with 10 μg / mL kanamycin;

[0057] 3) The sensitive microorganisms in each 1 mL of the above medium were recovered by centrifugation (3000 rpm, 10 minutes), and the recovered sensitive microorganisms ADPWH_recA were redissolved in 10 mL of LB medium for use.

[0058] 4) Add agarose powder purchased from Sigma-Aldrich into 100 mL of deionized water, and mix well to obtain an agarose solution...

Embodiment 3

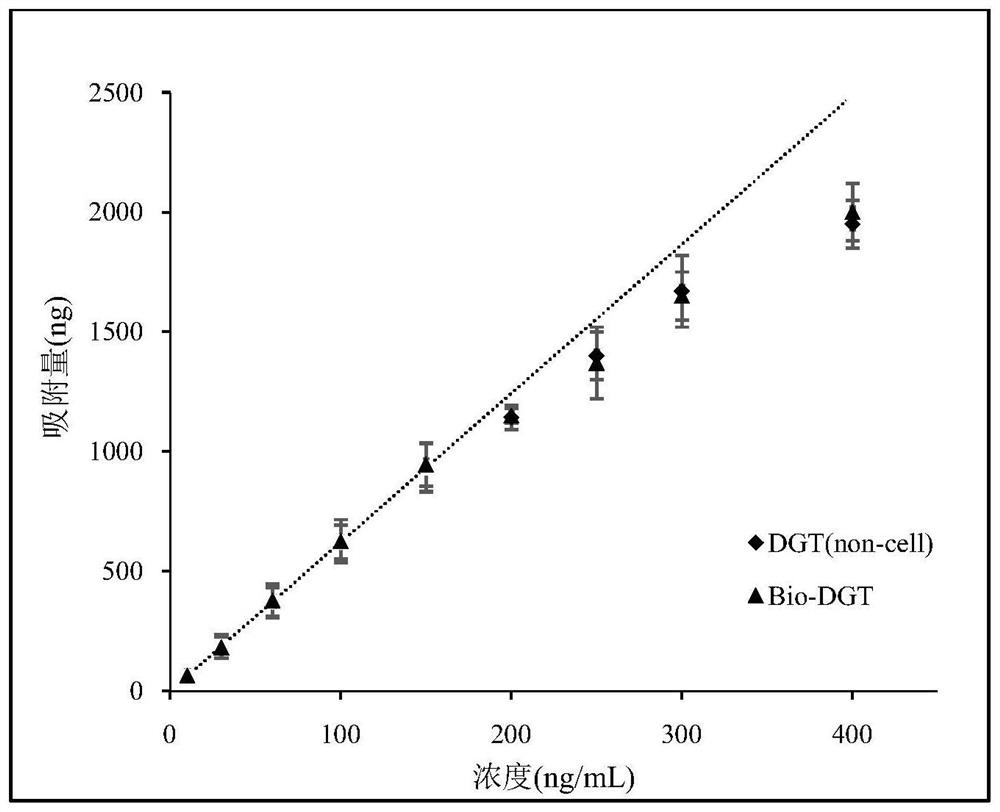

[0067] This embodiment is a comparison of the As concentration in the measured water body of the biofilm DGT device assembled in Example 2 and the conventional DGT device and the relationship with time. The diffusion membrane and the filter membrane of the conventional DGT device are the same as the biofilm DGT device. , the adsorption film adopts the iron oxide adsorption film which has adsorption effect on As. The method for preparing the iron oxide adsorption film is basically the same as the method for preparing the mixed adsorption film in Patent Example 1 with the Chinese patent application number "201510781428.9", except that only ferrous sulfate solution is prepared in the initial solution, and no Introducing aluminum ions and cerium ions, only the iron oxide adsorption film was prepared.

[0068] The above two DGT devices were used to measure the concentration of As in the water and the relationship with time. The specific steps are as follows:

[0069] 1) Solution p...

Embodiment 4

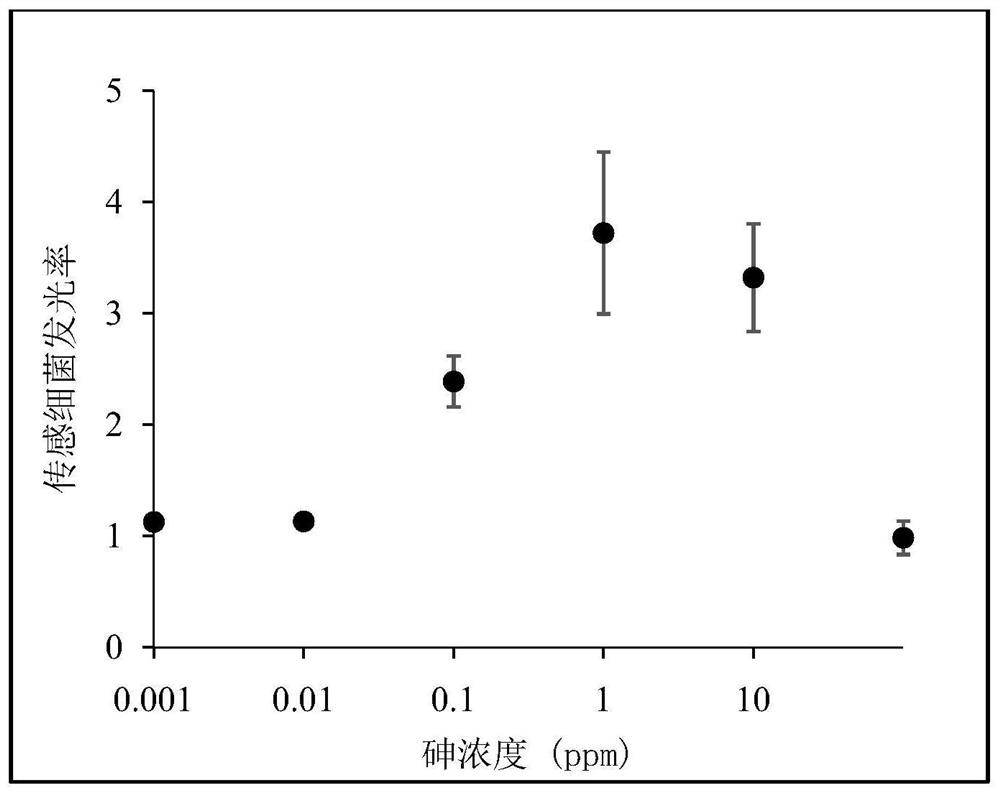

[0079] This example is the relationship between the response of the sensitive microorganism ADPWH_recA to As in the biofilm DGT and the predicted value of the genotoxicity model.

[0080] 1) Solution preparation: prepare As solutions with As concentrations of 1 μg / L, 10 μg / L, 100 μg / L, 1 mg / L, 10 mg / L, and 100 mg / L, the pH value of the solution is 6.0±0.5, and the ionic strength is 0.01 mol / L, the ionic strength is prepared by adding NaNO to deionized water 3 After preparation, the preparation is completed. In an open environment, use a magnetic stirrer to continuously stir the solution for at least 24 hours, so that the carbon dioxide concentration reaches equilibrium, and then start the experiment. During the experimental period, the magnetic stirrer was kept in a stirring state.

[0081] 2) After placing the DGT device of Example 2 in the above-mentioned solutions with different As concentrations for 48 hours, take it out for pretreatment and analysis. The pretreatment pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com