Catalyst for oxidative esterification of isobutene, preparation method and application thereof

An oxidative esterification and catalyst technology, which can be used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., and can solve the problem of catalyst economy. High, low catalytic activity of the catalyst, etc., to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method for the above-mentioned catalyst for oxidative esterification of isobutylene, said method comprising the steps of:

[0041] (1) The carrier is first contacted with an alkaline solution, and then contacted with a metal solution to prepare a metal-loaded carrier;

[0042] (2) contacting the metal-loaded carrier in step (1) with a reducing agent to react to prepare a catalyst precursor; optionally, roasting the catalyst precursor;

[0043] (3) The catalyst precursor in step (2) is loaded with a catalytic promoter to prepare the catalyst for oxidative esterification of isobutylene.

[0044] Wherein, step (1) specifically includes the following steps:

[0045](1-1) Immersing the carrier into an alkaline solution and drying to obtain a carrier loaded with an alkaline substance;

[0046] (1-2) Spray the metal solution onto the carrier carrying the alkaline substance, and the metal component and the alkaline substance u...

Embodiment 1

[0089] (1) Dissolve 4.0 g of sodium metasilicate nonahydrate in 40 mL of water, and add to 40 g of 5 mm silica pellets (water absorption: 1.0 mL / g) for impregnation. After the impregnating liquid is completely absorbed, place the silica pellets in an oven at 110° C. for 12 hours to obtain dried silica pellets.

[0090] (2) Dissolve 1.7g of sodium tetrachloropalladate and 0.2g of copper chloride dihydrate in 40mL of water to form a metal solution. By means of spraying and dipping, the metal solution is evenly sprayed on the above-mentioned dried silica pellets, and left to stand for 24 hours for alkalization precipitation to obtain precipitated silica pellets.

[0091] (3) Add 40mL of 20wt.% hydrazine hydrate solution to the precipitated silica pellets, reduce the metal component precipitated on the silica pellets, wash, filter, and dry to obtain a catalyst precursor.

[0092] (4) 2.0 g of potassium acetate was dissolved in 40 mL of water, impregnated in the catalyst precursor...

Embodiment 2

[0095] Change the 4.0g sodium metasilicate nonahydrate in step (1) of embodiment 1 to 3.0g sodium metasilicate nonahydrate, and keep other steps unchanged.

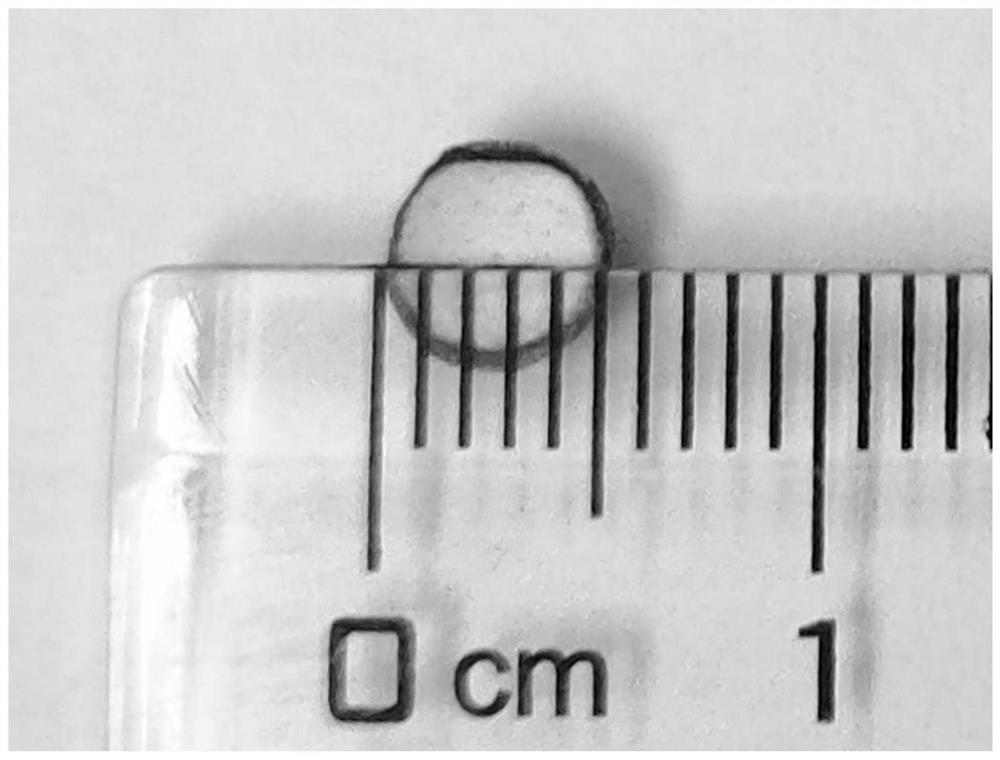

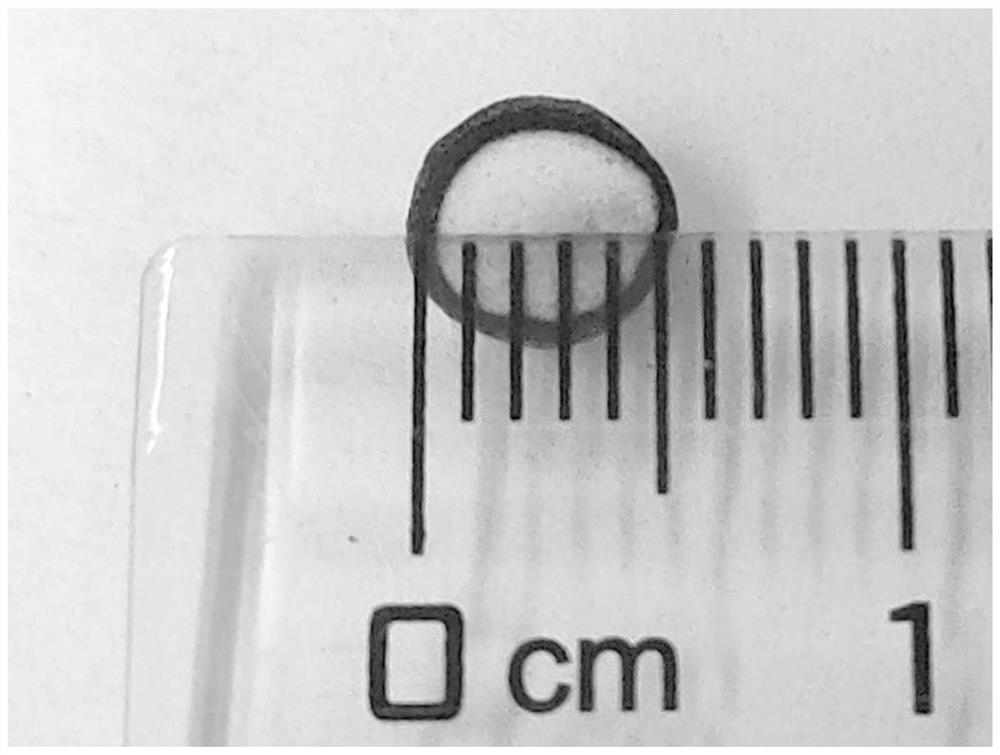

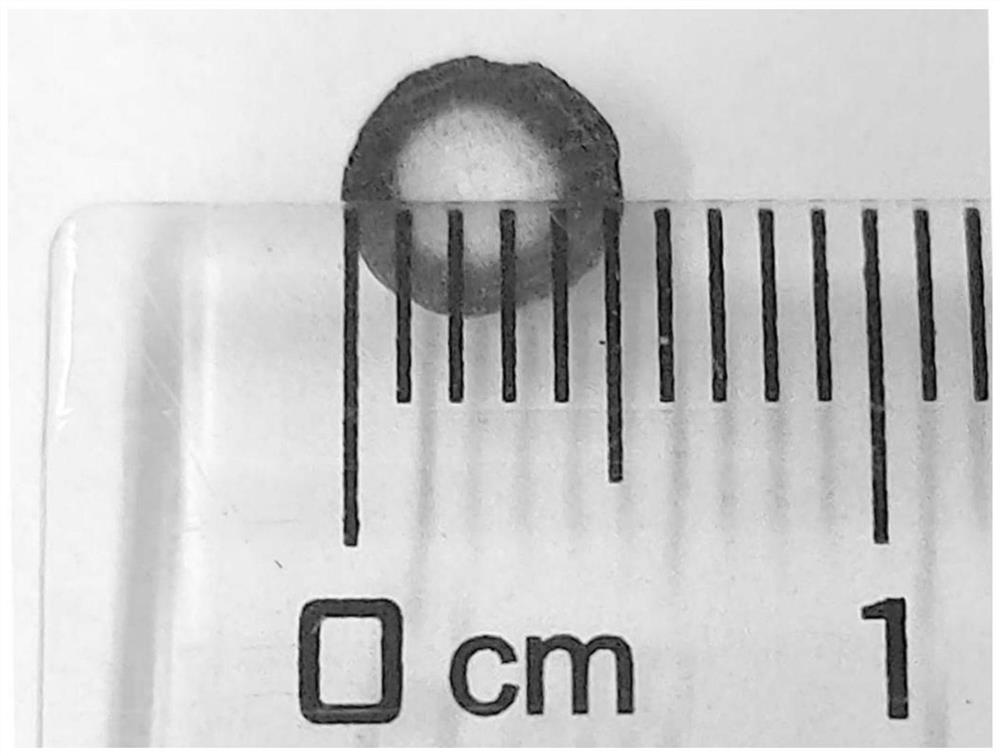

[0096] Catalyst cross section photo as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com