Transparent long-acting antistatic polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, applied in the field of transparent long-acting antistatic polypropylene composite material and its preparation, can solve the problems of harm to human body and electronic sensitive devices, deterioration of the quality of sensitive devices, reduction of service life, etc. , Improve surface gloss and transparency, improve the effect of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

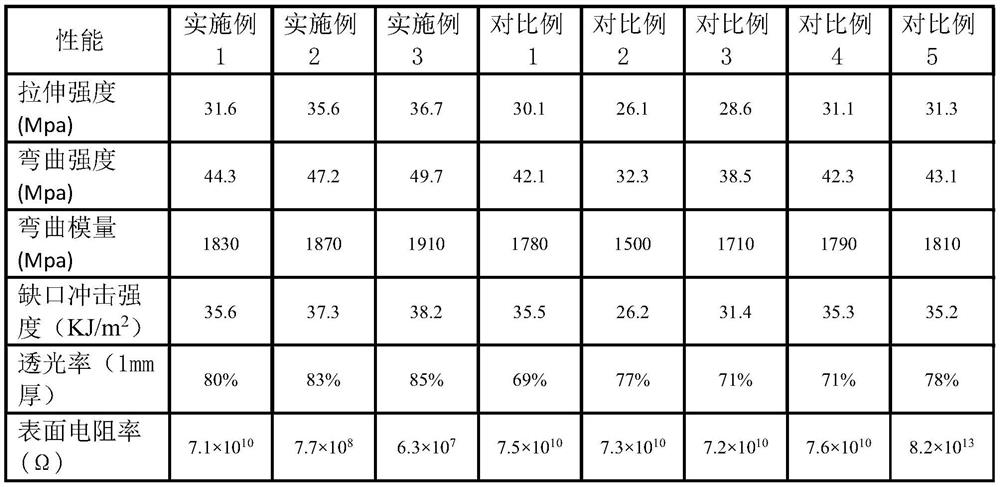

Examples

Embodiment 1

[0025] A transparent long-lasting antistatic polypropylene composite material, the raw materials for its preparation include the following components in parts by weight: 100 parts of random copolymerized polypropylene, 10 parts of ceramic particles treated with a silane coupling agent, and 1 part of a sorbitol nucleating agent 0.1 part, 0.1 part of calcium stearate, 0.1 part of composite antistatic agent, and 0.1 part of antioxidant 168; wherein, the composite antistatic agent is prepared by coating polyethylenedioxythiophene on carbon nanotubes.

[0026] The present invention also provides a preparation method for the above-mentioned transparent long-lasting antistatic polypropylene composite material, comprising the following steps:

[0027] (1) Weigh random copolymerized polypropylene, ceramic particles, transparent nucleating agent, lubricant, antioxidant according to the weight ratio, join in the high-speed mixer, fully mix uniformly, obtain main mixture;

[0028] (2) the...

Embodiment 2

[0031] A transparent long-lasting antistatic polypropylene composite material, the preparation raw materials include the following components in parts by weight: 100 parts of random copolymerized polypropylene, 15 parts of ceramic particles treated with silane coupling agent, 3 parts of sorbitol nucleating agent 0.2 part, 0.2 part of calcium stearate, 0.3 part of composite antistatic agent, and 0.2 part of antioxidant 168; wherein, the composite antistatic agent is prepared by coating polyaniline on carbon nanotubes.

[0032] The present invention also provides a preparation method for the above-mentioned transparent long-lasting antistatic polypropylene composite material, comprising the following steps:

[0033] (1) Weigh random copolymerized polypropylene, ceramic particles, transparent nucleating agent, lubricant, antioxidant according to the weight ratio, join in the high-speed mixer, fully mix uniformly, obtain main mixture;

[0034] (2) the main compound that step (1) o...

Embodiment 3

[0037] A transparent long-lasting antistatic polypropylene composite material, the preparation raw materials include the following components in parts by weight: 100 parts of random copolymerized polypropylene, 20 parts of ceramic particles treated with silane coupling agent, 5 parts of rosin-type nucleating agent 0.3 part, 0.3 part of calcium stearate, 0.5 part of composite antistatic agent, and 0.3 part of antioxidant 168; wherein, the composite antistatic agent is prepared by coating poly N, N diethylacrylamide on carbon nanotubes .

[0038] The present invention also provides a preparation method for the above-mentioned transparent long-lasting antistatic polypropylene composite material, comprising the following steps:

[0039] (1) Weigh random copolymerized polypropylene, ceramic particles, transparent nucleating agent, lubricant, antioxidant according to the weight ratio, join in the high-speed mixer, fully mix uniformly, obtain main mixture;

[0040] (2) the main comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com