PVC material composite water-based adhesive and preparation method thereof

A PVC material and adhesive technology, applied in the direction of adhesive, adhesive type, rosin adhesive, etc., can solve the problems of poor leveling, insufficient bonding strength, agglomeration and agglomeration, and achieve smooth surface and good leveling , the effect of good bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

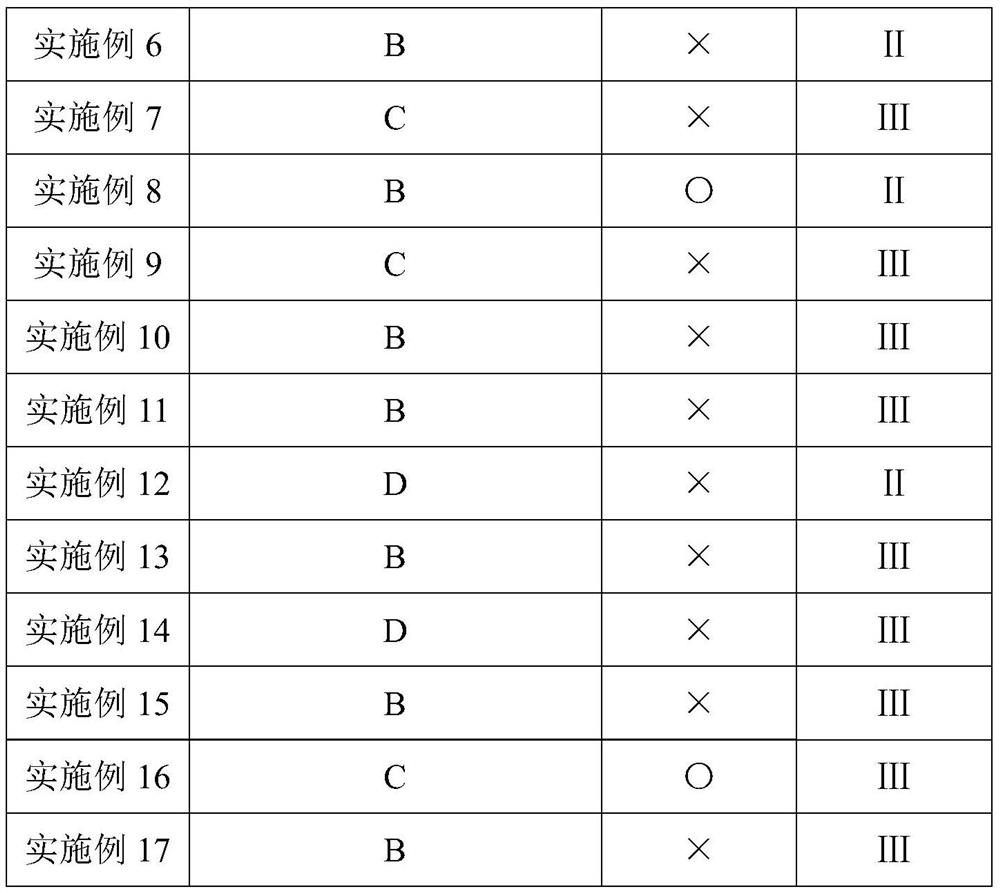

Examples

preparation example Construction

[0023] In a preferred embodiment, the preparation method of the polyurethane modified acrylic acid prepolymer comprises the following steps:

[0024] Step a: Add 2 to 4 parts of polyether polyol into the reaction kettle in parts by weight, vacuum dehydrate at 90 to 105°C for 1.5 to 2.5 hours, then cool down to 50 to 60°C, pass in nitrogen, and Add 11-18 parts of diisocyanate, raise the temperature to 70-75°C, and stir for 1-2 hours to obtain mixture A;

[0025] Step b: Add 1 to 4 parts of 2,2-dimethylolpropionic acid to 5 to 10 parts of N-methylpyrrolidone and mix evenly, then add to mixture A and stir for 1 to 3 hours;

[0026] Step c: heat up to 75-80°C, add 2-5 parts of hydroxyethyl acrylate and 1-3 parts of isopropanol and stir for 1-2 hours, cool down to 50-65°C, add 8-12 parts of methyl methacrylate, Continue to lower the temperature to below 40°C, add 1-2 parts of triethanolamine, stir for 0.3-0.7 hours, add 40-50 parts of water to obtain a polyurethane-modified acryli...

Embodiment 1

[0068] Embodiment 1 of the present invention provides a PVC material composite water-based adhesive, including the following raw materials: 42.5 parts of polyurethane modified acrylic prepolymer, 17.5 parts of petroleum resin, 10.5 parts of rosin resin, 5 parts of plasticizer, 7 parts of organosiloxane monomer 3 parts, 3 parts of initiator, 6 parts of accelerator.

[0069] The petroleum resin is Exxon carbon five resin, the model is E1310, and the softening point is 93°C. The rosin resin is a hydrogenated rosin resin, which can be purchased from Shanghai Lisen Chemical Co., Ltd., a first-grade hydrogenated rosin resin. The organosiloxane monomer is styrene ethyl trimethoxysilane. Described plasticizer is glycerol triglycidyl ether; Described initiator is potassium persulfate; Described accelerator is N, N-dimethylaniline and o-sulfonyl benzimide, the weight ratio of the two It is 1:0.6.

[0070] The preparation method of described polyurethane modified acrylic acid prepolym...

Embodiment 2

[0077] Embodiment 2 of the present invention provides a PVC material composite water-based adhesive, including the following raw materials: 35 parts of polyurethane modified acrylic prepolymer, 15 parts of petroleum resin, 9 parts of rosin resin, 4 parts of plasticizer, organosiloxane monomer 6.5 parts, 1 part of initiator, 5 parts of accelerator.

[0078] The petroleum resin is Exxon carbon five resin, the model is E1310, and the softening point is 93°C. The rosin resin is a hydrogenated rosin resin, which can be purchased from Shanghai Lisen Chemical Co., Ltd., a first-grade hydrogenated rosin resin. The organosiloxane monomer is styrene ethyl trimethoxysilane. Described plasticizer is glycerol triglycidyl ether; Described initiator is potassium persulfate; Described accelerator is N, N-dimethylaniline and o-sulfonyl benzimide, the weight ratio of the two It is 1:0.6.

[0079] The preparation method of described polyurethane modified acrylic acid prepolymer comprises the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com