Electrochemistry polishing liquid used for silver workpieces, application of electrochemistry polishing liquid and oxidation resistance method of silver workpieces

An electrochemical and polishing liquid technology, applied in the field of anti-oxidation and electrochemical polishing liquid, can solve the problems of pollution, health hazards of manufacturers, high processing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention has no special requirements on the preparation method of the electrochemical polishing liquid, and the preparation method known to those skilled in the art can be used.

[0027] The present invention also provides the application of the electrochemical polishing solution described in the above technical solution in inhibiting the oxidation of silver workpieces.

[0028] The invention provides a kind of anti-oxidation method of silver workpiece, comprises the following steps:

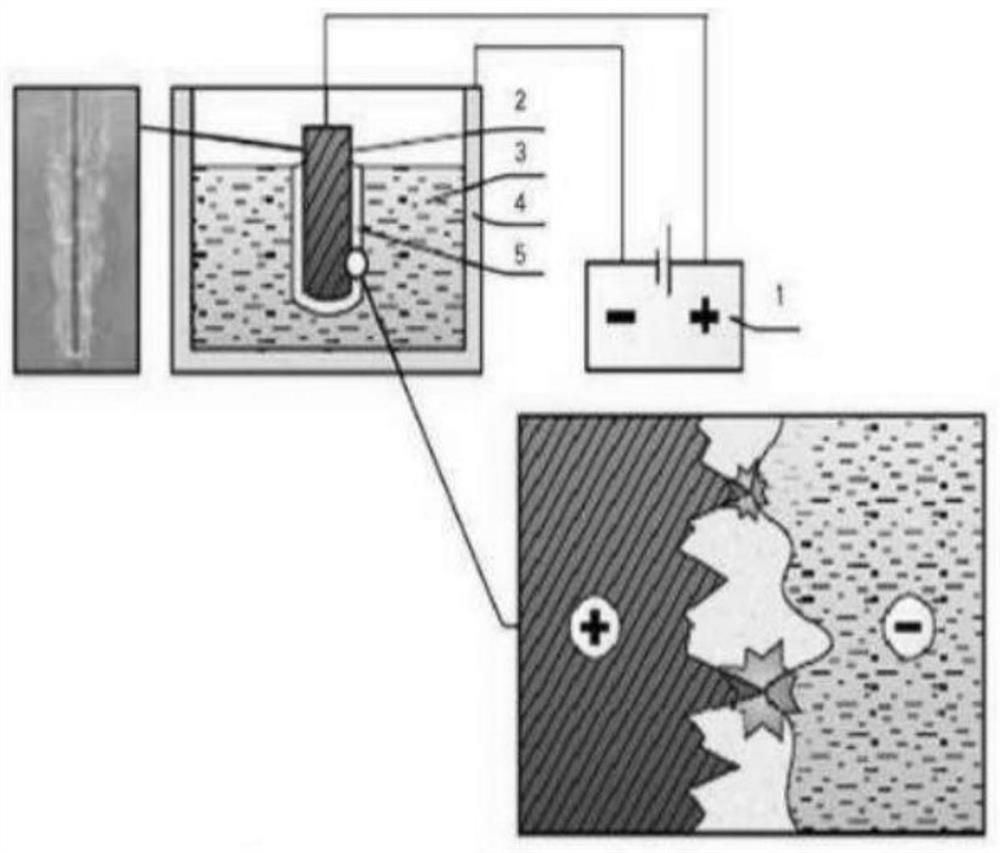

[0029] The silver workpiece is subjected to mechanical polishing, electrochemical polishing and physical polishing in sequence to obtain a silver workpiece with an anti-oxidation mirror effect; the method of electrochemical polishing includes: using the mechanically polished silver workpiece as an anode and a positive electrode of a DC stabilized voltage supply connected, and immersed in the polishing tank filled with the electrochemical polishing solution described in the ab...

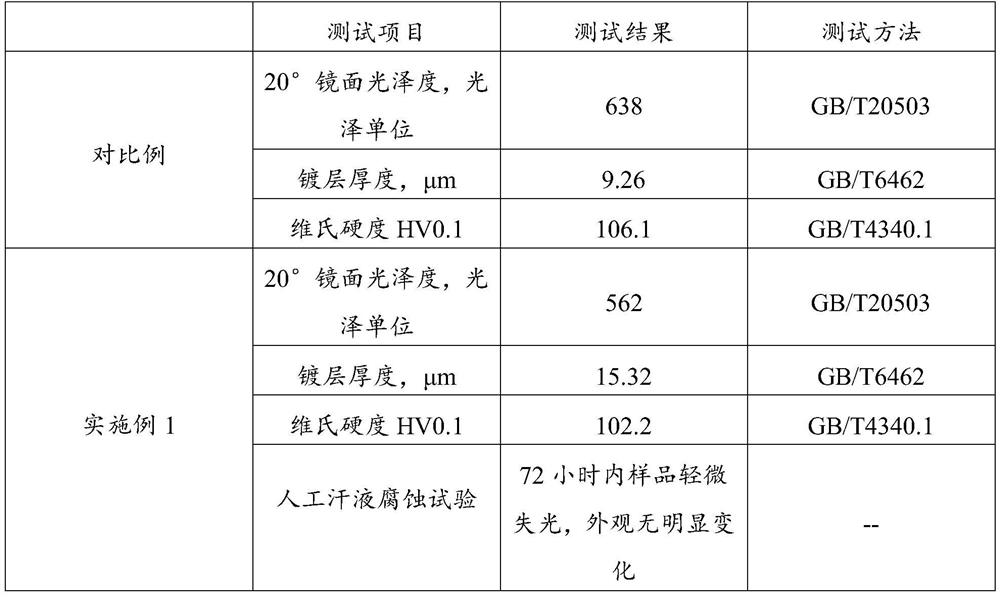

Embodiment 1

[0040] Put the silver jewelry on the mold holding table, and use 800 type sandpaper to polish the silver jewelry; then place the silver workpiece and 0.2cm high-purity zirconia beads figure 2 In the shown high-speed grinding centrifuge, mechanical polishing is carried out at 500r / min; the surface of the silver workpiece obtained by mechanical polishing is obviously rough, the brightness is not enough, and there are obvious particles under the electron microscope; figure 2 Among them, the silver jewelry is placed in the deep layer of high-purity zirconia beads, and the white part is high-purity zirconia beads.

[0041] The mechanically polished silver workpiece is used as the anode to connect with the positive pole of the DC stabilized voltage power supply, and immersed in the polishing tank filled with electrochemical polishing liquid; the stainless block tank is used as the cathode to connect with the negative pole of the DC stabilized voltage power supply, and immersed in t...

Embodiment 2

[0045] Put the silver jewelry on the mold holding table, and use 800 type sandpaper to polish the silver jewelry; then place the silver workpiece and 0.2cm high-gloss beads figure 2 In the high-speed grinding centrifuge shown, mechanical polishing is carried out at 700r / min;

[0046] The mechanically polished silver workpiece is used as the anode to connect with the positive pole of the DC stabilized voltage power supply, and immersed in the polishing tank filled with electrochemical polishing liquid; the stainless block tank is used as the cathode to connect with the negative pole of the DC stabilized voltage power supply, and immersed in the In the polishing tank; connect the direct current stabilized power supply and carry out electrochemical polishing to the silver workpiece; the composition of the electrochemical polishing liquid is: sodium sulfate 30g / L, sodium citrate 50g / L, sodium sulfite 3g / L, nitrous acid Sodium 2g / L, sodium lauryl sulfate 1g / L; The temperature of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com