Composite dispersion method used for polyimide chopped fibers

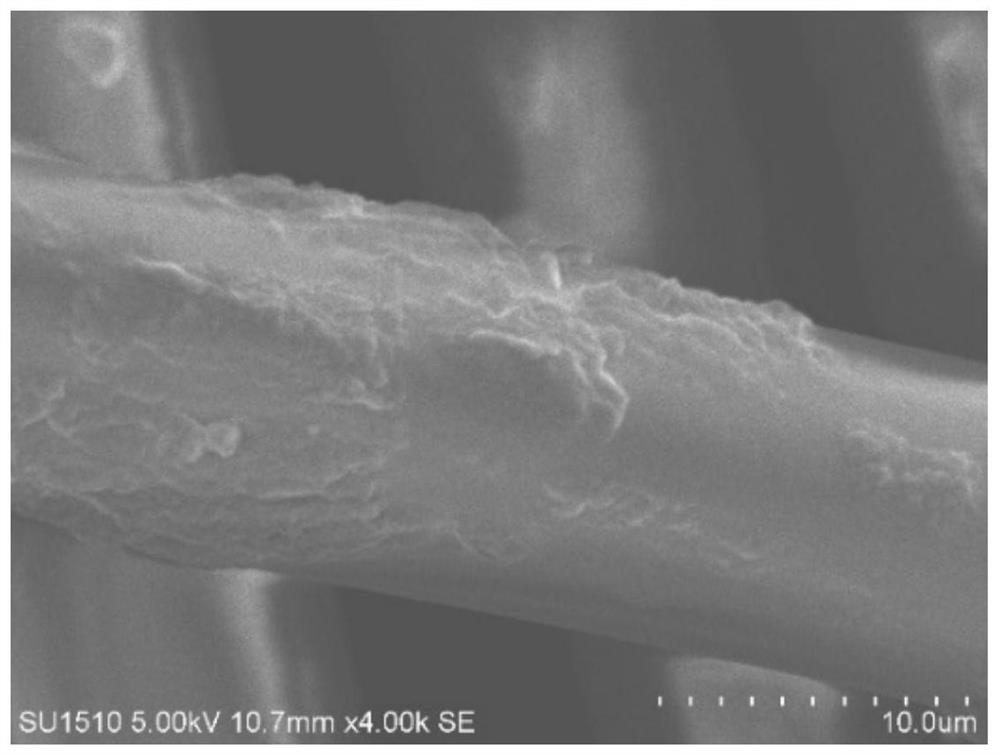

A technology of chopped fiber and polyimide, applied in the direction of fiber type, fiber treatment, fiber raw material treatment, etc., can solve the problems of unsuitable fiber dispersion for a long time, unable to effectively prevent fiber bending and flocculation into agglomerates, etc. The effect of increasing roughness and hydrophilic ability, overcoming van der Waals force, and increasing dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

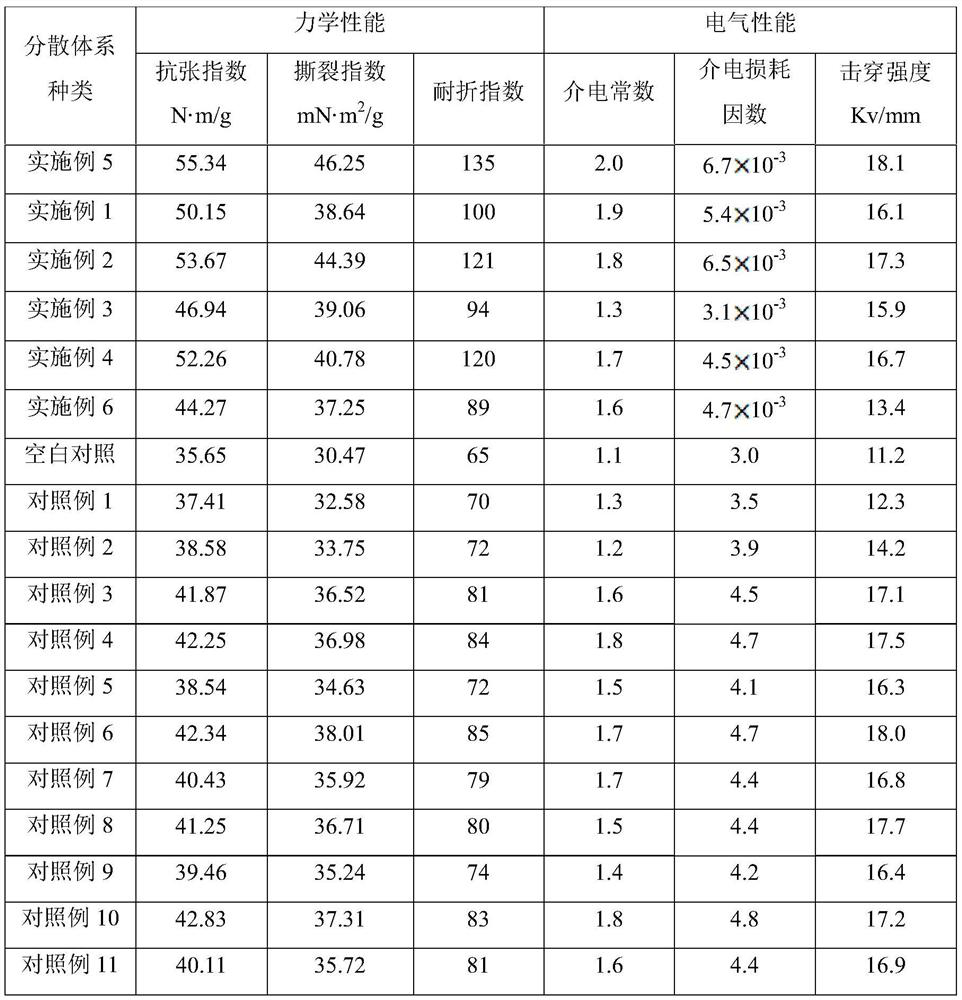

Examples

Embodiment 1

[0065] A method for preparing polyimide fiber base paper, comprising the steps of:

[0066] (1) Take 1000mL of water in a beaker, and add 6g of HCl into 1000mL of water at a ratio of 6.0:500 according to the mass-volume ratio g / mL to obtain an acid solution; according to the mass-volume (water) ratio g / mL is 1.0: 500 ratio, 2.0g of 3mm polyimide chopped fibers were added to the solution; the polyimide chopped fibers were filtered out through a filter screen after acid treatment at room temperature for 25min, washed with water and dried to obtain acid-treated polyimide fiber;

[0067] (2) According to the ratio of the mass volume ratio g / mL of hexamethylenediamine crystals and water to 0.9:500, and according to the ratio of 0.5:500 to the mass volume ratio g / mL of cationic surfactant CTMAB and water, weigh 1.8g Hexamethylenediamine crystals and 1.0g CTMAB were added to a beaker with 1000mL of water, and a mixed solution was obtained after the two were fully dissolved; then aci...

Embodiment 2

[0072] A method for preparing polyimide fiber base paper, comprising the steps of:

[0073] (1) Take 1000mL of water in a beaker, and mix 5.0g of H 2 SO 4 Add to 1000mL water, according to the ratio of mass volume (water) g / mL is 1.6:500, add 3.2g of 5mm polyimide chopped fibers into the solution; the polyimide chopped fibers are treated with acid at room temperature After 30 minutes, it is filtered through a filter screen, washed and dried to obtain acid-treated polyimide fibers;

[0074] (2) According to the ratio of the mass volume ratio g / mL of hexamethylenediamine crystals to water of 0.6:500, and according to the ratio of 0.4:500 of the mass volume ratio g / mL of the cationic surfactant CTMAB to water, weigh 1.2g Hexamethylenediamine crystals and 0.8g CTMAB were added to a beaker with 1000mL of water, and after the two were fully dissolved, a mixed solution was obtained; acid-treated polyimide chopped fibers were added to the mixed solution, and in a magnetic stirrer (...

Embodiment 3

[0079] A method for preparing polyimide fiber base paper, comprising the steps of:

[0080] (1) Take 1000mL of water in a beaker, and mix 10.4g of HNO 3 Add to 1000mL water, according to the ratio of mass volume (water) g / mL is 2.0:500, add 4.0g of 5mm polyimide chopped fibers into the solution; the polyimide chopped fibers are treated with acid at room temperature After 40min, it was filtered through a filter screen, washed with water and dried to obtain acid-treated polyimide fibers;

[0081] (2) According to the ratio of the mass volume ratio g / mL of hexamethylenediamine crystals and water to 0.8:500, and according to the ratio of 0.7:500 to the mass volume ratio g / mL of the cationic surfactant CTMAB and water, weigh 1.6g Hexamethylenediamine crystals and 1.4gCTMAB were added to a beaker with 1000mL of water, and a mixed solution was obtained after the two were fully dissolved; then the acid-treated polyimide chopped fibers were added to the mixed solution, and in a magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com