Method for preparing two-dimensional alloy/carbon composite nano-material by utilizing electroplating and organic sludge

A technology of organic sludge and nanomaterials, applied in nanotechnology for materials and surface science, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the limited effect of mixed sedimentation, metal components and organic components Difficult to achieve solid-liquid separation and other problems, to achieve high catalytic activity and economic benefits, high atomic utilization, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

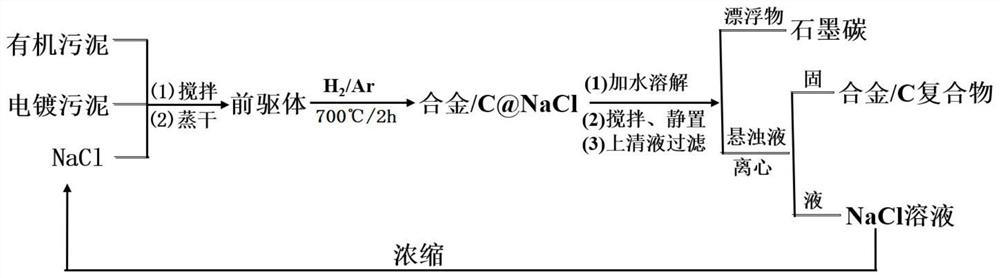

[0040] (1) 100 parts by weight of untreated electroplating sludge (mass fraction of heavy metals: 5.66% chromium, 7.15% iron, 3.71% nickel, 1.99% copper, 0.06% cobalt), 100% by weight After mixing 300 parts by weight of undried industrial organic sludge and 300 parts by weight of NaCl with a particle size of 200 mesh or less, mechanically stir at a speed of 1000 rpm at a constant temperature of 80°C until the water is evaporated to dryness, and the metal-containing component / organic carbon group is deposited. Part / NaCl precursor.

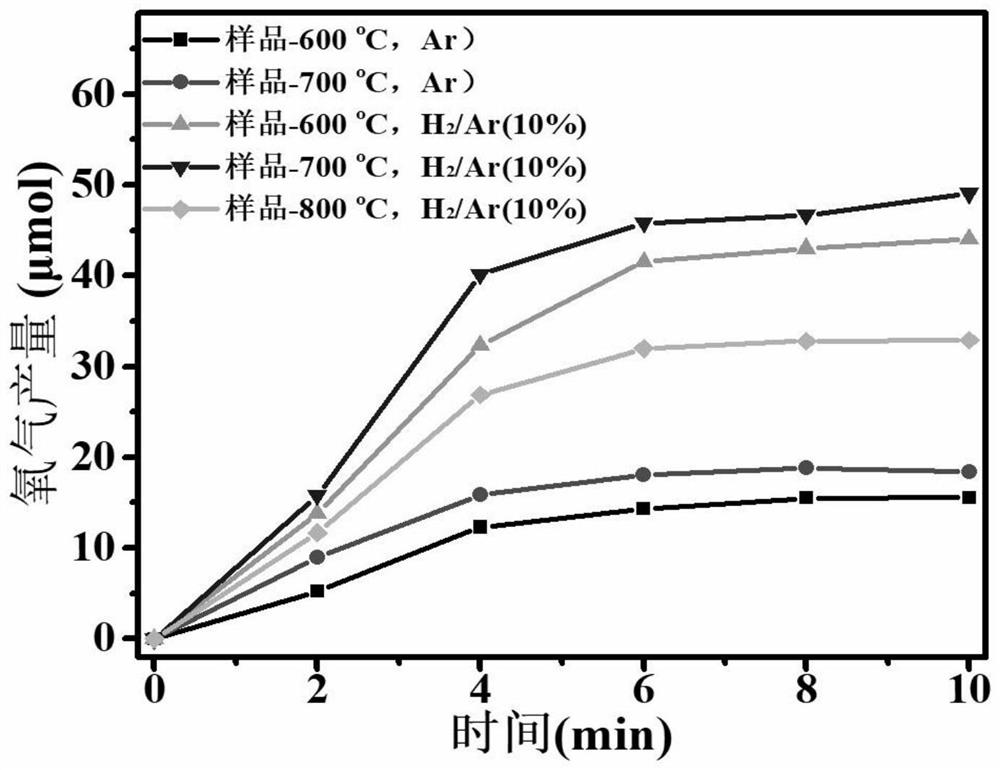

[0041] (2) Grinding the precursor obtained in step (1) into powder, placing it in a tube furnace, and roasting it under the atmosphere of hydrogen / argon gas mixture (hydrogen gas fraction is 10%) at 700°C for 2h to obtain alloy nanoparticles / Carbon@NaCl composite powder.

[0042] (3) After cooling the composite powder obtained in step (2), add it into 300 parts by weight of hot water (80° C.) and stir for 20 minutes to dissolve the NaCl template....

Embodiment 2

[0046] (1) 100 parts by weight of untreated electroplating sludge electroplating sludge (mass fraction of contained heavy metals: 5.34% chromium, 6.25% iron, 4.56% zinc, 3.35% nickel, 1.37% copper) , 50 parts by weight of undried industrial organic sludge, 400 parts by weight of Na with a particle size below 200 mesh 2 CO 3 After mixing, mechanically stir at a speed of 1500rpm at a constant temperature of 60°C until the water is evaporated to dryness, and the metal-containing component / organic carbon component / Na 2 CO 3 precursors.

[0047] (2) Grinding the precursor obtained in step (1) into powder, placing it in a tube furnace, and roasting it under the atmosphere of hydrogen / argon gas mixture (hydrogen gas fraction is 15%) at 750°C for 1h to obtain alloy nanoparticles / Carbon@Na 2 CO 3 Complex powder.

[0048] (3) Cool the composite powder obtained in step (2) and add it to 300 parts by weight of hot water (60°C) and stir for 20 minutes to dissolve Na 2 CO 3 templat...

Embodiment 3

[0051] (1) 100 parts by weight of untreated electroplating sludge electroplating sludge (mass fraction of heavy metals: 5.19% chromium, 3.96% zinc, 3.28% nickel, 1.76% copper, 0.13% cobalt) , 150 parts by weight of undried industrial organic sludge, 200 parts by weight of K 2 SO 4 After mixing, mechanically stir at a speed of 800rpm at a constant temperature of 70°C until the water evaporates to dryness, and deposit a metal-containing component / organic carbon component / K 2 SO 4 precursors.

[0052] (2) Grinding the precursor obtained in step (1) into powder, placing it in a tube furnace, and roasting it for 2 hours in an atmosphere of 900° C. hydrogen / argon gas mixture (hydrogen gas fraction is 5%) to obtain alloy nanoparticles / Carbon@K 2 SO 4 Complex powder.

[0053] (3) Cool the composite powder obtained in step (2) and add it to 300 parts by weight of hot water (70°C) and stir for 40 minutes to dissolve K 2 SO 4 template. After stirring, let it stand still, the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com