Application of pdes in compression-resistant self-healing three-dimensional stereo sensor, three-dimensional stereo sensor and its preparation method and application

A three-dimensional, sensor technology, applied in the field of sensors, can solve the problems that it is difficult to meet the construction of high-complexity three-dimensional structure, limit the development of sensor space structure, and the mechanical strength cannot be formed, so as to achieve high-efficiency self-repair ability and sensitive strain sensing effect , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 4

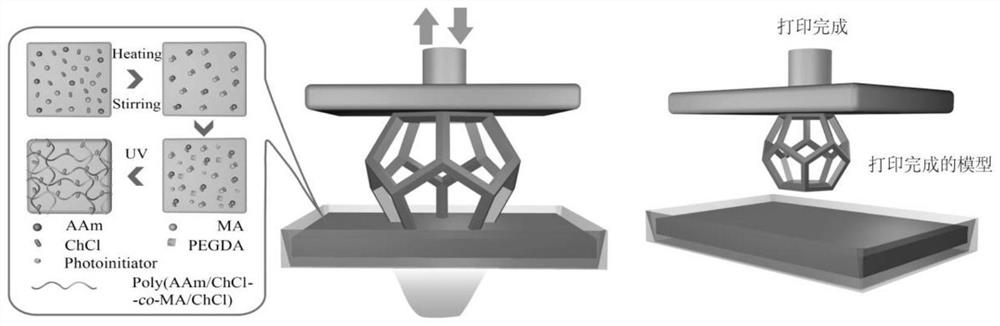

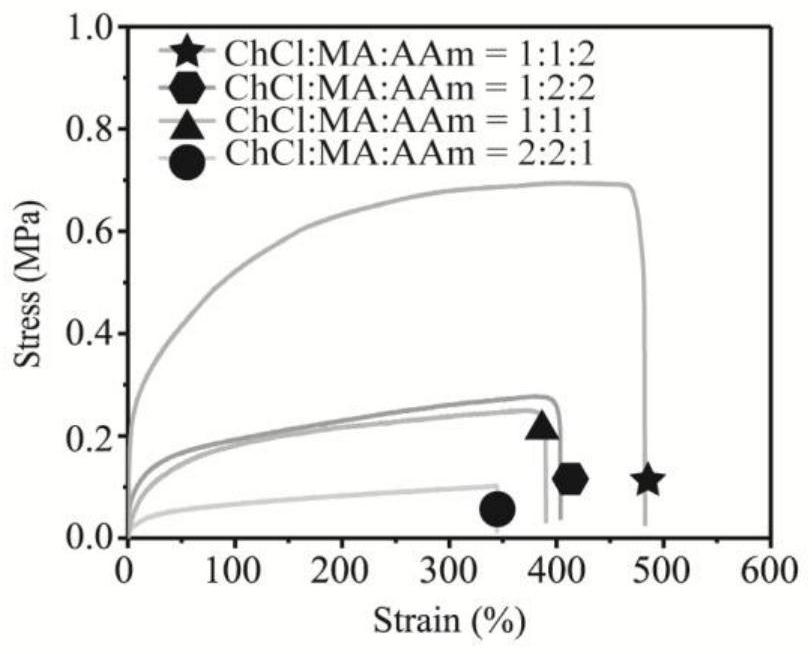

[0056] The preparation of 3D printing precursor solution, the preparation method is:

[0057] (1) Preparation of PDES: Acrylamide, choline chloride and maleic acid were dried in a vacuum oven at 50 °C for 4 h before using the materials. Choline chloride, maleic acid, and acrylamide were weighed and mixed according to the ratio shown in Table 1, and the mixture was stirred with 2,6-di-tert-butyl-4-methylphenol accounting for 0.2w% of the total mixture, And heated at 70 °C for 2 hours to form a transparent homogeneous solution polymerizable deep eutectic solvent (PDES), the prepared PDES was cooled to room temperature and stored in a dry and cool vacuum desiccator.

[0058] (2) Preparation of 3D printing precursor solution: add choline chloride, maleic acid, acrylamide total amount of 1% cross-linking agent poly(ethylene glycol) diacrylate (PEG(200)) and chloride Choline, maleic acid, acrylamide total amount of 0.5% photoinitiator TPO; then stirred at room temperature of 25°C u...

Embodiment 5~11

[0063] The preparation of 3D printing precursor solution, the preparation method is:

[0064] (1) Preparation of PDES: Acrylamide, choline chloride and maleic acid were dried in a vacuum oven at 50 °C for 4 h before using the materials. Weigh and mix choline chloride, maleic acid, and acrylamide in a molar ratio of 1:1:2, and stir the mixture with 2,6-di-tert-butyl-4-methylphenol accounting for 0.2w% of the total mixture , and heated at 70 °C for 2 hours to form a transparent homogeneous solution of polymerizable deep eutectic solvent (PDES), the prepared PDES was cooled to room temperature, and stored in a dry and cool vacuum desiccator.

[0065] (2) Preparation of 3D printing precursor solution: add crosslinking agent poly(ethylene glycol) diacrylate (PEG(200)) and photoinitiator TPO according to the ratio shown in Table 2, and then stir at room temperature of 25°C until The solution became clear and colorless again. The prepared precursor solution was placed in a black li...

Embodiment 12

[0075] The 3D printing precursor solution was prepared according to the method of Examples 1 to 12, wherein the molar ratio of choline chloride, maleic acid, and acrylamide was 1:1:2, and the mass ratio of photoinitiator to PDES was 0.5%. The mass ratio of the joint agent to PDES is 1%. The digital model of the three-dimensional sensor was designed by Unigraphics software and layered by SparkStudio software to form a thickness of 50 μm. These were then sent to a SLA 3D printer (SparkMaker.USA) with 410nm 24W UV light for printing. The exposure time of each layer is 6s, and the exposure intensity is 255.

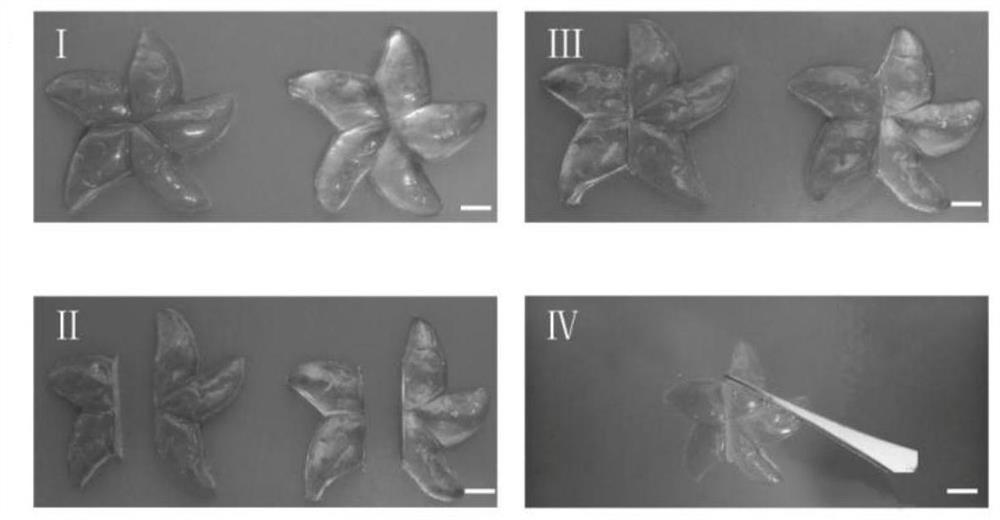

[0076] The three-dimensional model designed by the software and the corresponding 3D printed physical picture of the three-dimensional model are as follows: Figures 5 to 8 shown, where Figures 5 to 8 The picture on the left is the three-dimensional model designed by the software. Figures 5 to 8 The picture on the right is the actual picture printed out. By comparing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com