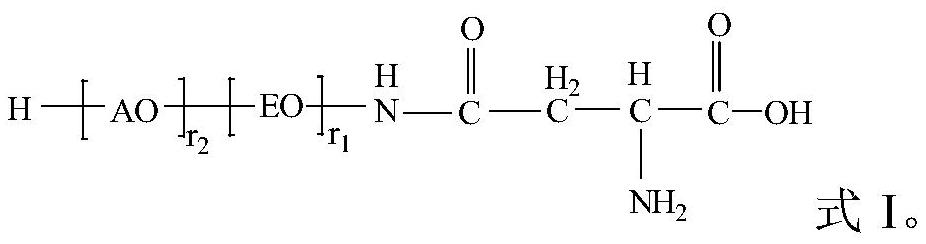

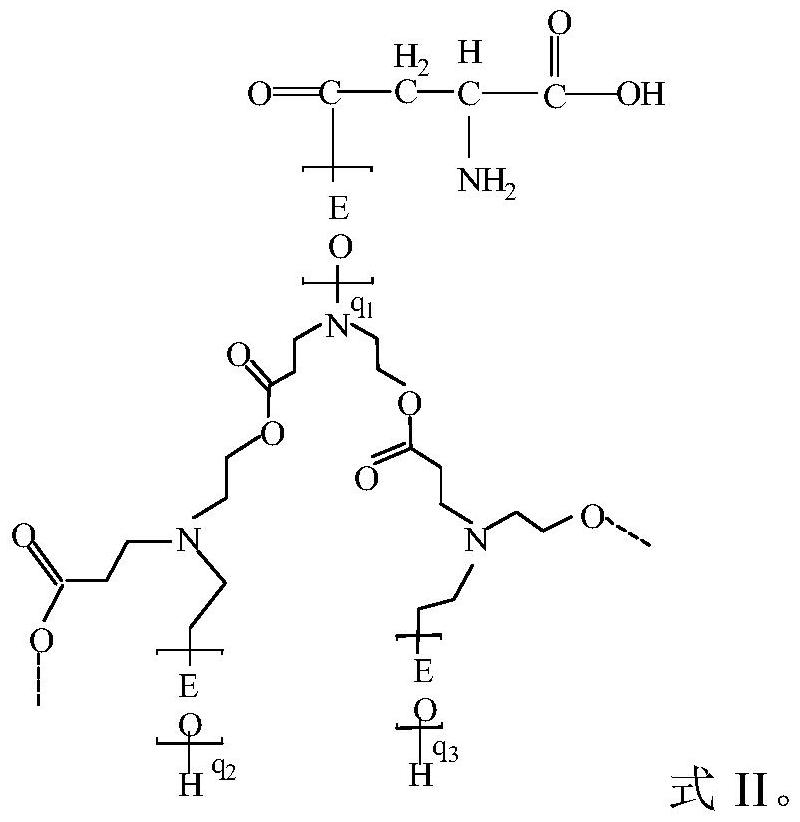

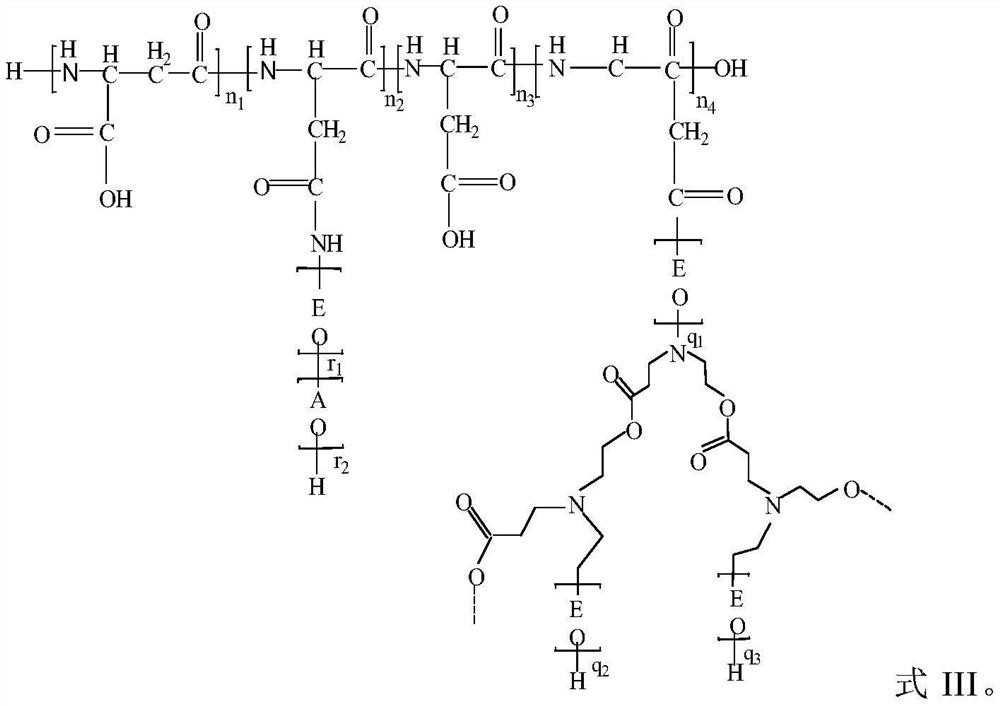

Ultra-high-performance water reducing agent and preparation method thereof

An ultra-high-performance, water-reducing agent technology, applied in the field of concrete admixtures, can solve the problems of rapid concrete slump loss, poor workability of fresh concrete, high concrete viscosity, etc., to increase the steric hindrance effect, reduce viscosity, The effect of improving the water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An ultra-high performance water reducing agent is prepared by the following method:

[0035] (1) 29.05g of propylene oxide and 70.4g of ethylene oxide were added to the reaction vessel, mixed uniformly, and fed with nitrogen; 2 The temperature was raised to 80 °C under a protective atmosphere, and 0.22 g of potassium hydroxide catalyst and 2.26 g of cuprous chloride polymerization inhibitor were added. 2 The temperature was raised to 120°C under a protective atmosphere, the reaction was continued for 3 h, cooled to room temperature, the product was extracted with ethyl acetate, washed 10 times with water, filtered, dried, and the solvent was removed to obtain side chain I.

[0036] (2) 18g of ethylene oxide, 2g of initiator aziridine, 25g of diethanolamino carboxylic acid were mixed in N 2 Under a protective atmosphere, react at 90 °C for 4 h to prepare a polydiethanolaminocarboxylic acid-ethylene oxide adduct, add 20 g L-aspartic acid, and add 20 g of L-aspartic acid ...

Embodiment 2

[0039] An ultra-high performance water reducing agent is prepared by the following method:

[0040] (1) 34.86g of propylene oxide and 74.8g of ethylene oxide were added to the reaction vessel, mixed uniformly, and nitrogen was introduced into the reaction vessel. 2 The temperature was raised to 85°C under a protective atmosphere, and 0.37g of sodium hydroxide catalyst and 2.46g of cuprous chloride polymerization inhibitor were added. 2 The temperature was raised to 100°C under a protective atmosphere, and after continuing the reaction for 2 h, the product was cooled to room temperature, the product was extracted with ethyl acetate, washed with water 12 times, filtered, dried, and the solvent was removed to obtain side chain I.

[0041] (2) by 22g ethylene oxide, 4g initiator aziridine, 10g diethanolamino carboxylic acid in N 2 Under a protective atmosphere, react at 100 °C for 4 h to prepare polydiethanolaminocarboxylic acid-ethylene oxide adduct, add 25 g of L-aspartic acid, a...

Embodiment 3

[0044] An ultra-high performance water reducing agent is prepared by the following method:

[0045] (1) 40.67g of propylene oxide and 79.2g of ethylene oxide were added to the reaction vessel, mixed uniformly, and nitrogen was introduced into the reaction vessel. 2 The temperature was raised to 90 °C under a protective atmosphere, and 0.53 g of potassium oxide catalyst and 3.99 g of cuprous chloride polymerization inhibitor were added. 2 The temperature was raised to 110°C under a protective atmosphere, and the reaction was continued for 4 hours, then cooled to room temperature. The product was extracted with ethyl acetate, washed with water for 10 times, filtered, dried, and the solvent was removed to obtain side chain I.

[0046] (2) 19g ethylene oxide, 3g initiator aziridine, 20g diethanolamino carboxylic acid were mixed in N 2 Under a protective atmosphere, react at 95 °C for 4 h to prepare polydiethanolaminocarboxylic acid-ethylene oxide adduct, add 20 g L-aspartic acid,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com