Epoxy SMC resin composition and preparation method thereof

A resin composition and epoxy resin technology, applied in the field of SMC resin composite materials, can solve the problems of low structural strength and modulus, poor heat resistance, SMC material pollution, etc., and achieve high structural strength and modulus, heat resistance and other problems. Good, prevent powder agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

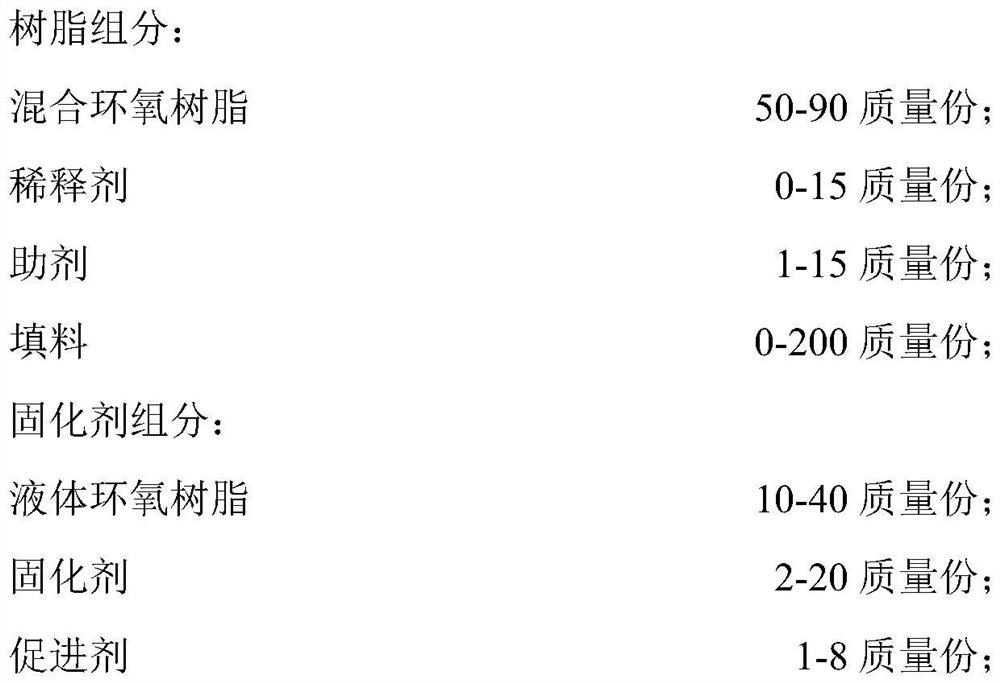

Method used

Image

Examples

Embodiment 1

[0031] Put 83g of bisphenol A glycidyl ether type liquid epoxy resin NPEL-128, 6g of internal release agent, 0.75g of defoamer, and 0.75g of sizing agent into the reactor and start stirring. After the resin is melted and mixed evenly, add fillers to the reaction and stirring at a high speed to ensure that the material temperature is lower than 120°C, and mix uniformly to obtain material 1; 17g of bisphenol A glycidyl ether type liquid epoxy resin NPEL-128, 7g of dicyandiamide, 1.5g of organic urea, composed of Mix the grinding material and stir in the reaction kettle. The stirring temperature does not exceed 45°C. After mixing evenly, perform three-roll grinding. After grinding, the particle size of the mixture is less than 10 μm to obtain material 2; reduce the temperature of material 1 to below 50°C, Add material 2 to material 1, stir for 0.5h, and vacuum defoam to obtain SMC resin; finally add 4.4g of alicyclic amine and stir evenly to obtain epoxy SMC resin paste; impregnat...

Embodiment 2

[0037] Put 78g bisphenol A glycidyl ether type liquid epoxy resin NPEL-128, 5g alicyclic glycidyl ester epoxy resin TDE-85, 6g internal mold release agent, 0.75g defoamer, 0.75g sizing agent in the reactor Start stirring in the middle, and after the resin is melted and mixed evenly, add the filler in the reaction kettle and carry out high-speed stirring to ensure that the temperature of the material is lower than 120°C, and mix evenly to obtain material 1; 17g of bisphenol A glycidyl ether type liquid epoxy resin NPEL- 128. The mixed abrasive composed of 7g dicyandiamide and 1.5g organic urea is stirred in a reaction kettle at a temperature not exceeding 45°C. After mixing evenly, three-roll grinding is carried out. After grinding, the particle size of the mixture is less than 10 μm to obtain a material 2. Lower the material temperature of material 1 to 45°C, add material 2 into material 1, stir for 1 hour, and vacuum defoam to obtain SMC resin; finally add 5g of alicyclic amin...

Embodiment 3

[0039] Put 81g of bisphenol A glycidyl ether type liquid epoxy resin NPEL-128, 2g of cycloaliphatic epoxy resin TTA-21, 6g of internal mold release agent, 0.75g of defoamer, and 0.75g of wetting agent in the reactor and start stirring , after the resin is melted and mixed evenly, add the filler in the reaction kettle and stir at a high speed to ensure that the temperature of the material is lower than 120°C, and mix evenly to obtain material 1; 17g of bisphenol A glycidyl ether type liquid epoxy resin NPEL-128, 7g Dicyandiamide, 1.5g of organic urea, and a mixed abrasive composed of dicyandiamide, 1.5g of organic urea, are stirred in a reaction kettle, and the stirring temperature does not exceed 45°C. After mixing evenly, three-roll grinding is carried out. After grinding, the particle size of the mixture is less than 10 μm to obtain material 2; The material temperature of material 1 is lowered to 49°C, and material 2 is added to material 1, stirred for 45 minutes, and vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com