Carbon microsphere lubricating liquid antiwear agent and antiwear lubricating liquid

A technology of carbon microspheres and lubricating fluid, applied in the field of lubricating fluid additives, can solve the problems of high manufacturing cost of pitch-based carbon microspheres, poor anti-wear effect of lubricating fluid anti-wear agents, etc., and achieve good surface condition, low price, and easy preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

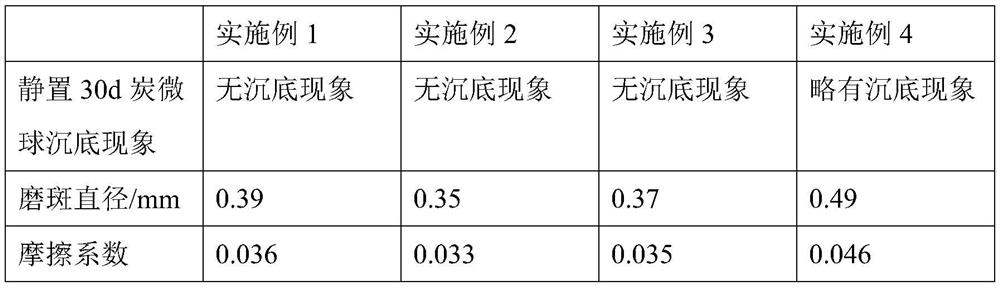

Embodiment 1

[0030] This embodiment provides a kind of carbon microsphere lubricating liquid antiwear agent, is prepared by the following method:

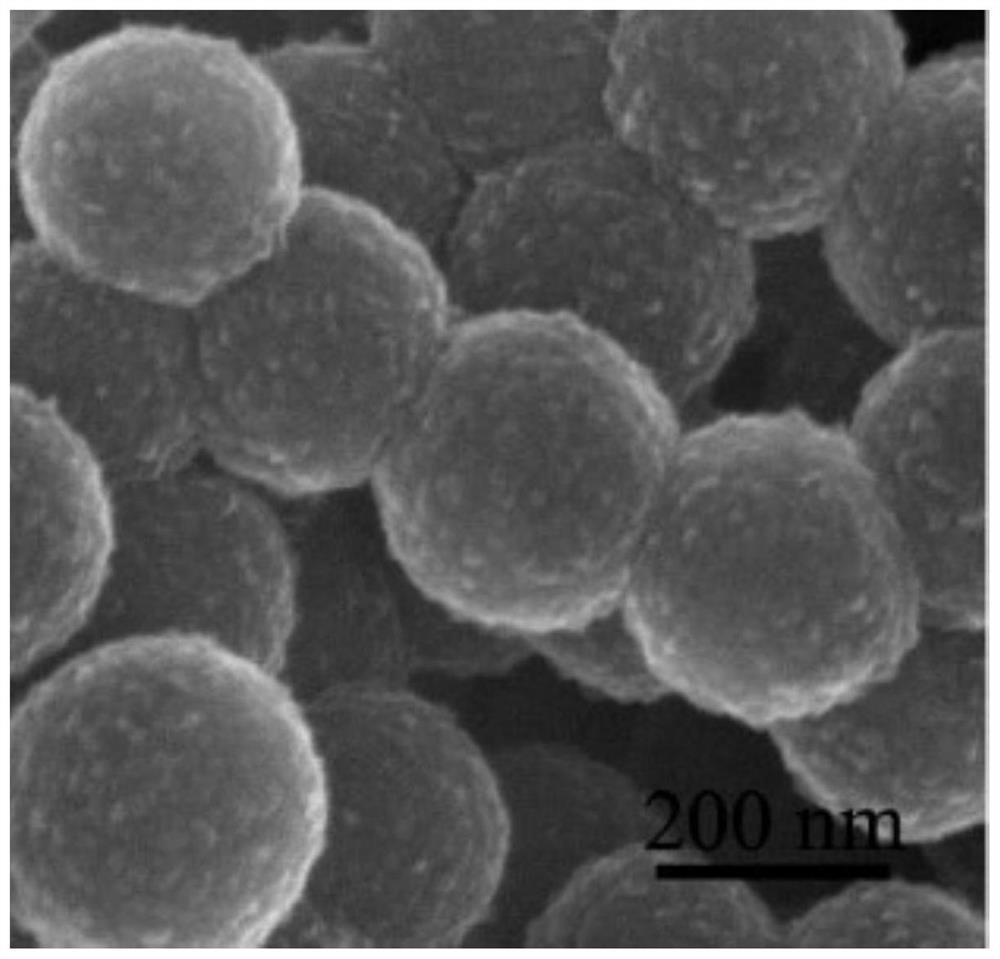

[0031] Using coal-based pitch as raw material, under the pressure of 500 °C and 0.5 MPa, undergo thermal condensation reaction for 5 hours to obtain mesophase pitch carbon microspheres with a particle size of about 20 microns;

[0032] In an air atmosphere, the mesophase pitch carbon microspheres were pre-oxidized at 280°C for 2 hours;

[0033] Under a nitrogen atmosphere, heat-treat the pre-oxidized mesophase pitch carbon microspheres at 1000°C for 2 hours to obtain carbon microspheres;

[0034] Put the carbon microspheres in a mixed solution of sulfuric acid and nitric acid with a volume ratio of 1:1, and heat to 80°C to oxidize the surface of the carbon microspheres for 6 hours;

[0035] Disperse the carbon microspheres after surface oxidation treatment in tetrahydrofuran, add octadecylamine as a modifier, and react at 150°C for 6 hours to ...

Embodiment 2

[0039] This embodiment provides a kind of carbon microsphere lubricating liquid antiwear agent, is prepared by the following method:

[0040] Using petroleum asphalt as raw material, at 350°C and 1.5MPa pressure, undergo thermal condensation reaction for 12 hours to obtain mesophase pitch carbon microspheres with a particle size of about 30 microns;

[0041] In an air atmosphere, the mesophase pitch carbon microspheres were pre-oxidized at 350 °C for 1 h;

[0042] Under a nitrogen atmosphere, heat-treat the pre-oxidized mesophase pitch carbon microspheres at 2000°C for 1 hour to obtain carbon microspheres;

[0043] Put the carbon microspheres in a mixed solution of sulfuric acid and nitric acid with a volume ratio of 2:1, and heat to 150°C to oxidize the surface of the carbon microspheres for 5 hours;

[0044] Disperse the surface oxidized carbon microspheres in toluene, add oleic acid as a modifier, and react at 120°C for 12 hours to obtain a lubricating liquid antiwear agen...

Embodiment 3

[0048] This embodiment provides a kind of carbon microsphere lubricating liquid antiwear agent, is prepared by the following method:

[0049] Using coal-based pitch as raw material, under the pressure of 500°C and 2 MPa, undergo thermal condensation reaction for 10 hours to obtain mesophase pitch carbon microspheres with a particle size of about 30 microns;

[0050] In an air atmosphere, the mesophase pitch carbon microspheres were pre-oxidized at 200°C for 5h;

[0051] Under a nitrogen atmosphere, heat-treat the pre-oxidized mesophase pitch carbon microspheres at 500°C for 5 hours to obtain carbon microspheres;

[0052] Put the carbon microspheres in a mixed solution of sulfuric acid and nitric acid with a volume ratio of 1:2, and heat to 50°C to oxidize the surface of the carbon microspheres for 12 hours;

[0053] Disperse the carbon microspheres after surface oxidation treatment in N-methylpyrrolidone, add stearic acid as a modifier, and react at 50°C for 24 hours to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com