Multi-stage centrifugal pump for saline injection

A salt water injection and centrifugal pump technology, which is applied to the components, pumps, and pump devices of the pumping device for elastic fluids, which can solve the problem that the high water delivery volume cannot be completed at a high speed, the maintenance cost is high, and the injection pressure is unstable. and other problems, to achieve a wide range of process pressure and flow requirements, facilitate the utilization and efficiency of working hours, and ensure the effect of consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and corresponding embodiment, the present invention is described in detail, and following embodiment is carried out under the premise of technical solution of the present invention, has provided detailed embodiment and concrete operation process, but protection scope of the present invention does not Limited to the following examples.

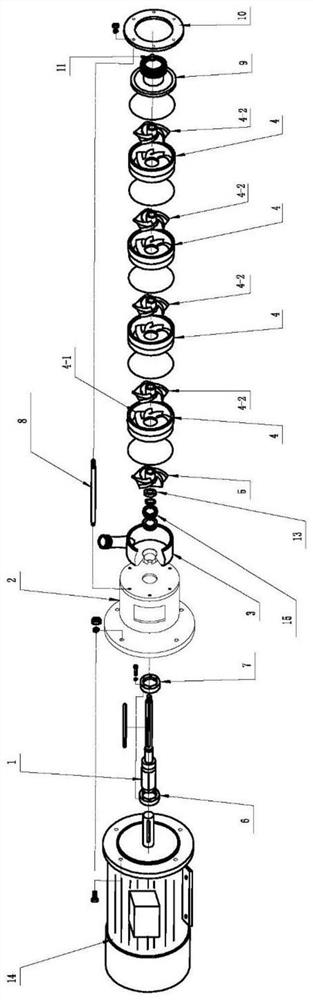

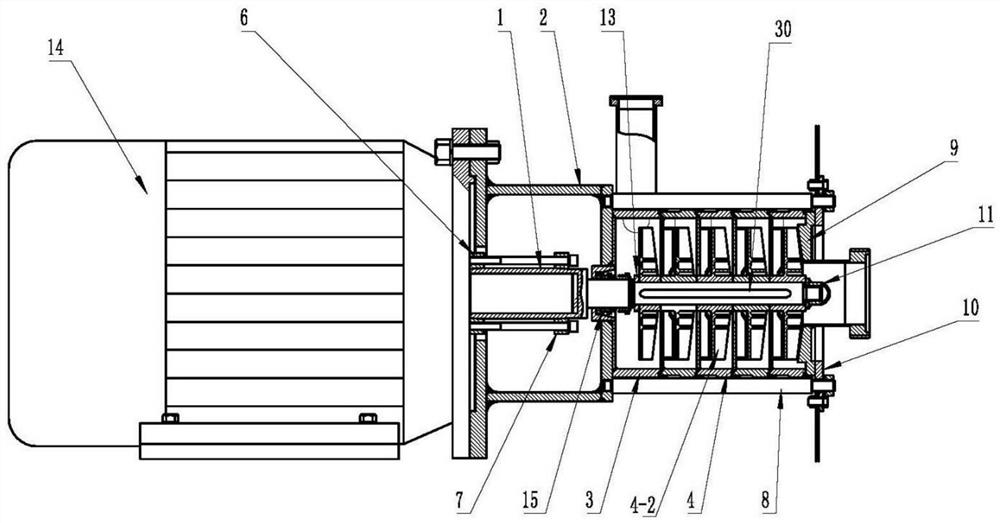

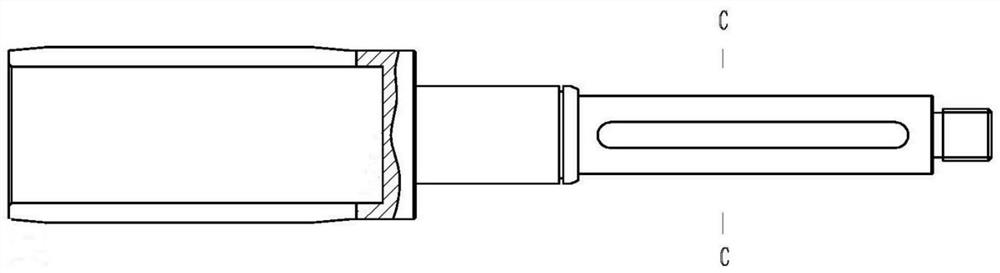

[0033] Such as figure 1 As shown, a multi-stage centrifugal pump for brine injection according to the present invention includes, from left to right: a motor 14, a lower lock plate 6, a water pump shaft 1, an upper lock plate 7, a connecting plate 2, a base 3, and a mechanical seal 15 , the first impeller 5, 4 pump casing groups, the front plate 9 and the pressure plate 10. It is not difficult for those skilled in the art to understand that the number of pump casing groups can be adjusted according to actual needs.

[0034] Each pump casing group includes: pump casing 4 and the second impe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com