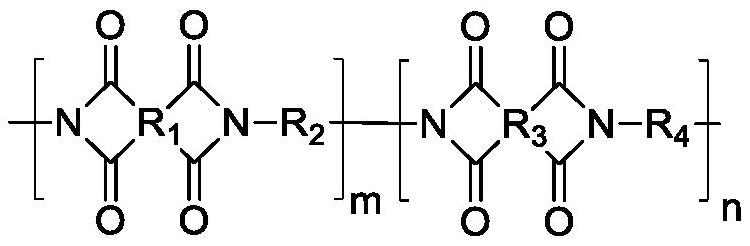

Cross-linked network-shaped silicon-carbon negative electrode binder and silicon-carbon negative electrode plate

A cross-network and binder technology, applied in the direction of negative electrodes, battery electrodes, structural parts, etc., can solve the problems of poor bonding performance, poor cycle stability, high internal resistance of batteries, etc., to improve cycle reversibility, stretch The effect of high strength and strong expansion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

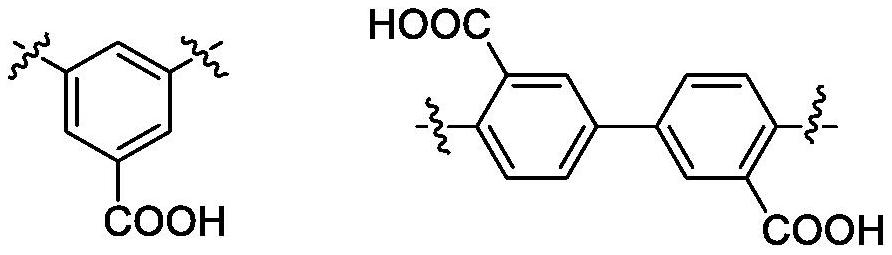

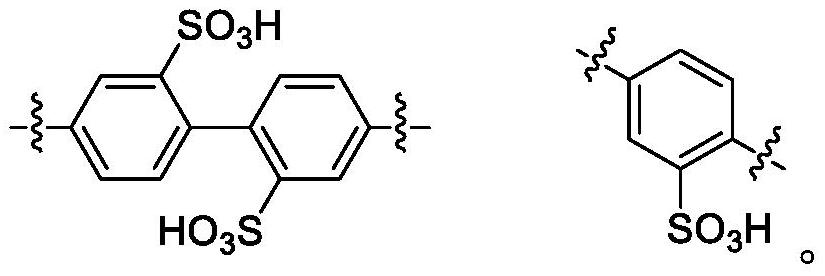

[0027] A kind of cross-network silicon carbon negative electrode binder, its preparation method comprises the steps:

[0028] S1. Under nitrogen protection, pour 1.128g (6mmol) 2,5-diaminobenzenesulfonic acid, 0.608g (4mmol) 3,5-diaminobenzoic acid, 50mL m-cresol and 0.607g (6mmol) triethylamine Put it into a three-necked flask, heat to 60°C and dissolve all diamine monomers, then cool to room temperature, add 3.22g (10mmol) 3,3',4,4'-benzophenone tetracarboxylic dianhydride to the above solution , stirred at room temperature for 4 hours to obtain a polyamic acid solution with a solid content of 10% by weight; slowly raised the temperature of the polyamic acid solution to 180 ° C, and maintained this temperature for 18 hours, cooled to room temperature, and then washed with a large amount of methanol to obtain a solid precipitate , filter the solid precipitate and pulverize, and dry under vacuum at 100°C to obtain sulfonated polyimide in the form of triethylamine salt; soak th...

Embodiment 2

[0034] A kind of cross-network silicon carbon negative electrode binder, its preparation method comprises the steps:

[0035] S1. Under nitrogen protection, pour 1.128g (6mmol) 2,5-diaminobenzenesulfonic acid, 0.608g (4mmol) 3,5-diaminobenzoic acid, 50mL m-cresol and 0.607g (6mmol) triethylamine Put it into a three-necked flask, heat to 60°C and all the diamine monomers are dissolved, then cool to room temperature, add 3.583g (10mmol) diphenylsulfonetetracarboxylic dianhydride to the above solution, and stir at room temperature for 4 hours to obtain a solid content of It is a 10wt% polyamic acid solution; the polyamic acid solution is slowly heated to 180° C., and maintained at this temperature for 18 hours, cooled to room temperature, and then washed with a large amount of methanol to obtain a solid precipitate, which is filtered and pulverized. Vacuum drying under ℃ obtains the sulfonated polyimide that exists in the form of triethylamine salt; Soak the sulfonated polyimide ...

Embodiment 3

[0040] A cross-linked silicon carbon negative electrode binder whose preparation method is the same as in Example 1, except that in step S1, 3.263g (10mmol) diphenyl sulfide tetracarboxylic dianhydride is used to replace 3.22g (10mmol) 3, 3', 4, 4'-benzophenone tetracarboxylic dianhydride is used as a raw material, and the structural formula of the obtained sulfonated polyimide is

[0041] Wherein, the preparation method of the silicon-carbon negative electrode sheet is the same as that of Example 1, except that the adhesive glue solution described in this embodiment is selected, and the above-mentioned silicon-carbon negative electrode sheet is assembled into a button battery according to the method described in Example 1. Charge and discharge test, the specific test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com