Preparation method of titanium alloy surface with low reflectivity to visible light

A low-reflectivity, titanium alloy technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complex manufacturing process, titanium alloy surface damage, high equipment cost, etc., and achieve easy and absorbing process parameters. The effect of stable performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a titanium alloy surface with low reflectivity to visible light, comprising the steps of:

[0031] (1) Surface cleaning pretreatment:

[0032] The TC4 titanium alloy sample to be treated is cleaned in an ultrasonic cleaner filled with deionized water, and then cleaned with absolute ethanol (purity: >99.8%), and the surface of the titanium alloy sample is dried with compressed air or Dry naturally at room temperature, pay attention to cleanliness and dust prevention, and obtain clean titanium alloy samples for later use.

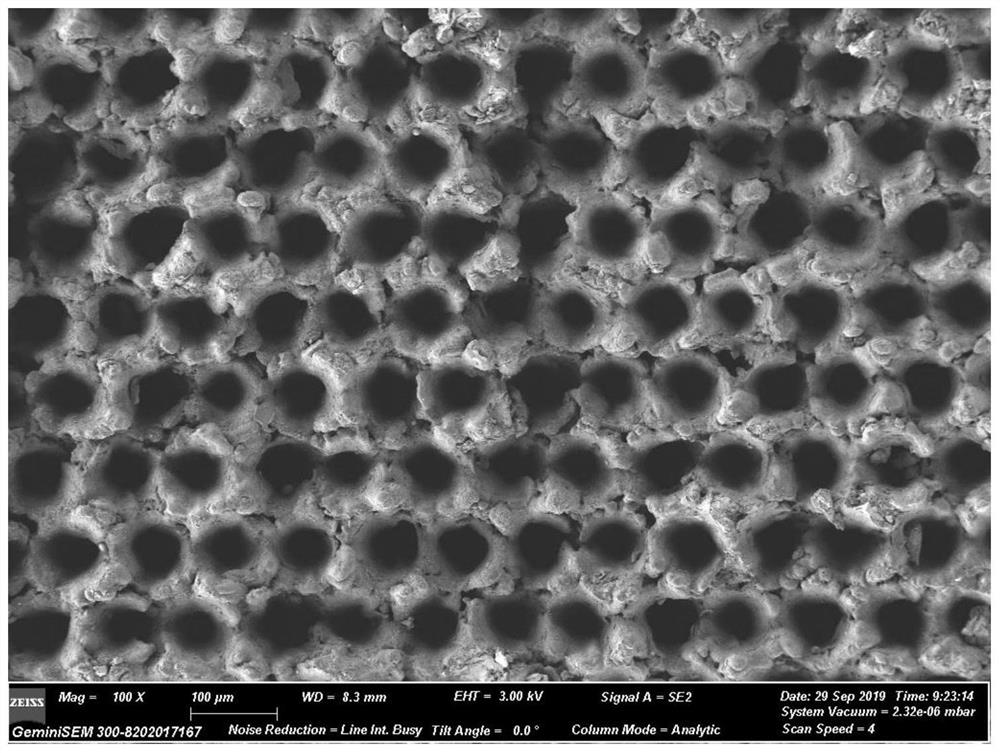

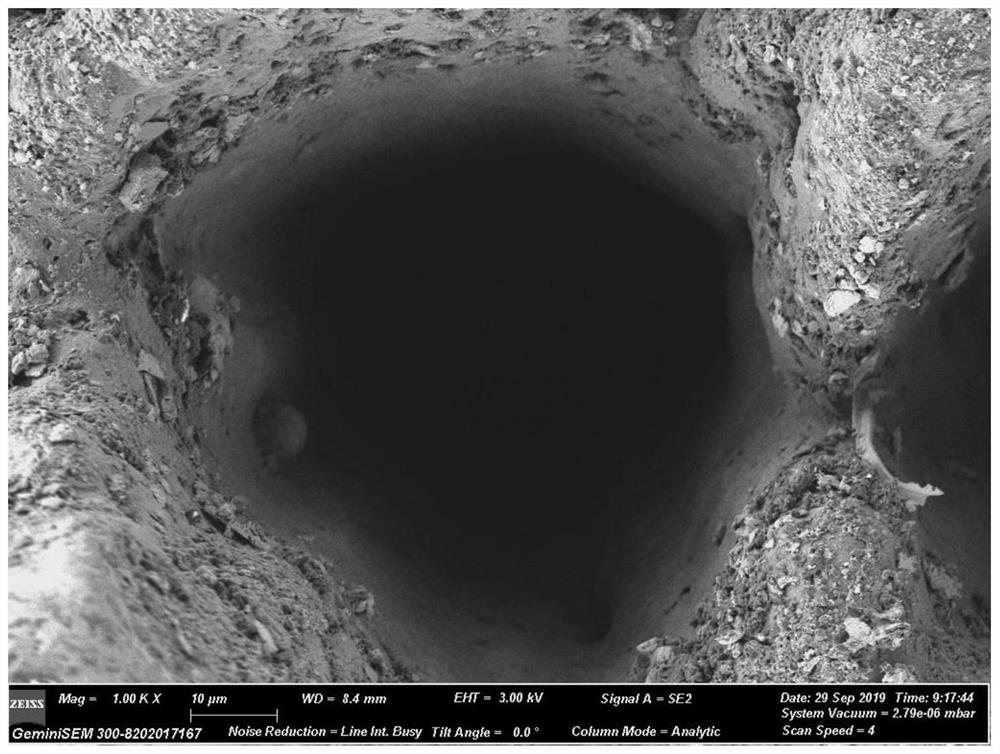

[0033] (2) Nanosecond laser preparation of pit-like nano-micro-nano tertiary structures on the surface of titanium alloys:

[0034] (a) Put the four corners of the aforementioned titanium alloy sample up and place it flat on the workbench, with air between the bottom surface of the titanium alloy sample and the workbench. First scan the surface of the sample with a focused laser beam along the X direction, the laser wavelength ...

Embodiment 2

[0042] A method for preparing a titanium alloy surface with low reflectivity to visible light, comprising the steps of:

[0043] (1) Surface cleaning pretreatment:

[0044] The TC4 titanium alloy sample to be treated is cleaned in an ultrasonic cleaner filled with deionized water, and then cleaned with absolute ethanol (purity: >99.8%), and the surface of the titanium alloy sample is dried with compressed air or Dry naturally at room temperature, pay attention to cleanliness and dust prevention, and obtain clean titanium alloy samples for later use.

[0045] (2) Nanosecond laser preparation of pit-like nano-micro-nano tertiary structures on the surface of titanium alloys:

[0046] (a) Put the four corners of the aforementioned titanium alloy sample up and place it flat on the workbench, with air between the bottom surface of the titanium alloy sample and the workbench. First scan the surface of the sample with a focused laser beam along the X direction. The laser wavelength ...

Embodiment 3

[0052] A method for preparing a titanium alloy surface with low reflectivity to visible light, comprising the steps of:

[0053] (1) Surface cleaning pretreatment:

[0054] The TC4 titanium alloy sample to be treated is cleaned in an ultrasonic cleaner filled with deionized water, and then cleaned with absolute ethanol (purity: >99.8%), and the surface of the titanium alloy sample is dried with compressed air or Dry naturally at room temperature, pay attention to cleanliness and dust prevention, and obtain clean titanium alloy samples for later use.

[0055] (2) Nanosecond laser preparation of pit-like nano-micro-nano tertiary structures on the surface of titanium alloys:

[0056] (a) Put the four corners of the aforementioned titanium alloy sample up and place it flat on the workbench, with air between the bottom surface of the titanium alloy sample and the workbench. First scan the surface of the sample with a focused laser beam along the X direction, the laser wavelength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com