Preparation method of nanometer SiC capable of being used as negative electrode material of lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in the field of lithium-ion batteries, can solve problems such as complex synthesis routes, coarse particles, and lack of purity, and achieve the effects of simple process, low energy consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

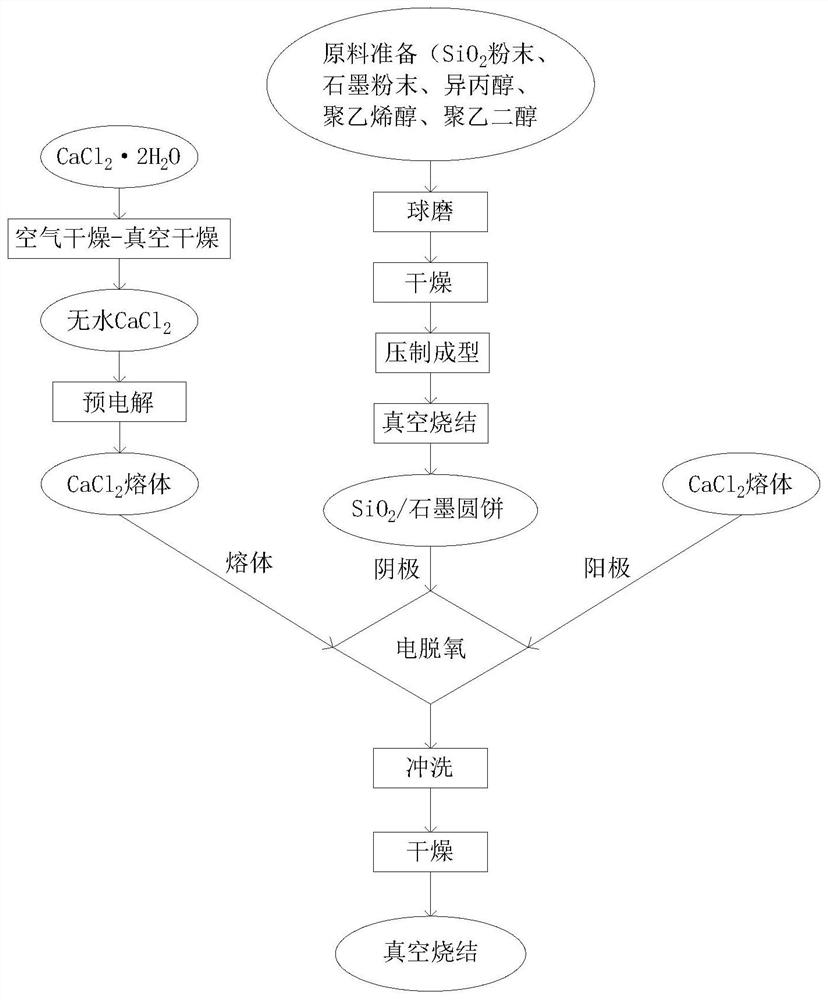

Method used

Image

Examples

Embodiment 1

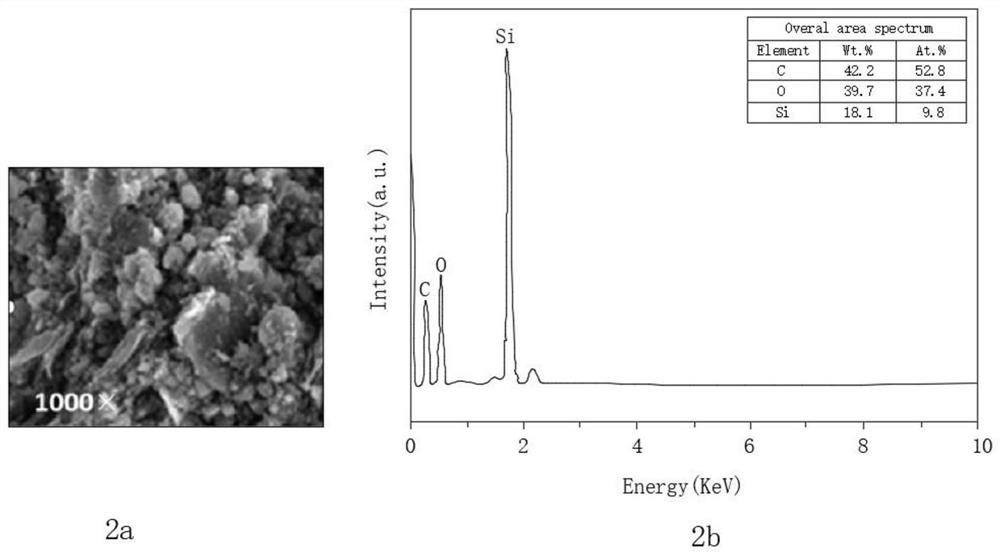

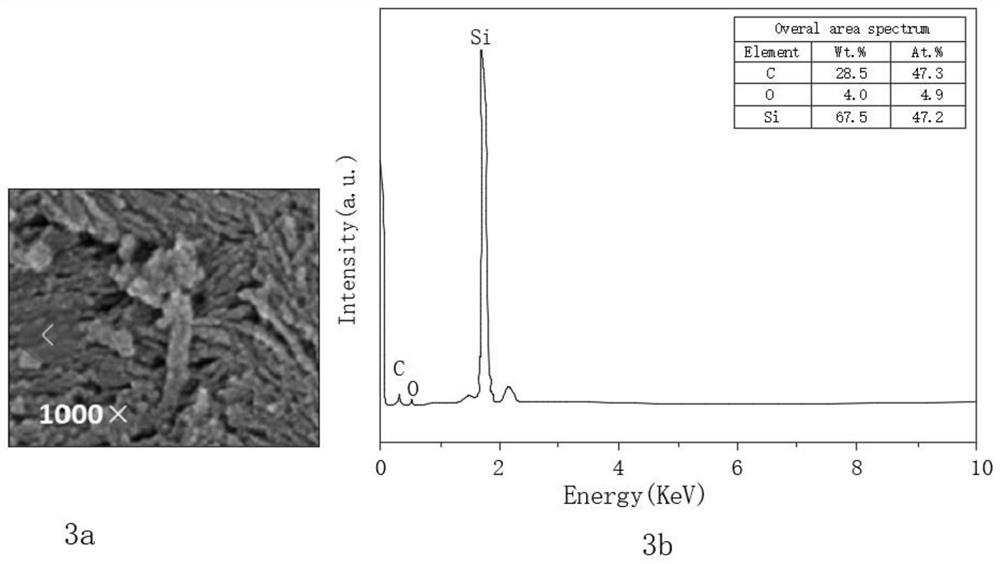

[0045] First weigh 98 parts of isopropanol, 1 part of polyvinyl alcohol, and 0.5 parts of polyethylene glycol, put them into a ball mill tank, stir properly with a glass rod, and then weigh 10 parts of SiO 2 The powder and 15 parts of graphite powder should be properly stirred with a glass rod and then ball milled. After being fully dispersed, take it out and dry it in a drying oven at 100°C. Press it into a 0.4g round cake with a diameter of 12mm under a pressure of 5MPa. , transferred to a high-temperature oven for sintering at 1200°C, the sintering time is 2.5h, and the sintering atmosphere is Ar+3vt%H 2 , in addition, take 550g CaCl 2 2H 2 O was dried in air at 180°C for 48h and then vacuum-dried at the same temperature for 24h, or air-dried at 260°C for 12h and then vacuum-dried at the same temperature for 6h to obtain CaCl 2 , weigh the CaCl prepared in the previous step 2 About 400g is placed in an alumina crucible, and then placed in a vertical high-temperature rea...

Embodiment 2

[0048] First weigh 99 parts of isopropanol, 1.2 parts of polyvinyl alcohol, and 1 part of polyethylene glycol, put them into a ball mill tank, stir properly with a glass rod, and then weigh 5 parts of SiO 2 The powder and 8 parts of graphite powder were properly stirred with a glass rod and started ball milling. After being fully dispersed, they were taken out and dried in an oven at 110°C. Under a pressure of 8MPa, they were pressed into a 1g round cake with a diameter of 18mm. Transfer to a high temperature oven for sintering at 1250°C, the sintering time is 3h, and the sintering atmosphere is Ar+4vt%H 2 , In addition, take 550g CaCl 2 2H 2 O was dried in air at 180°C for 48h and then vacuum-dried at the same temperature for 24h, or air-dried at 280°C for 12h and then vacuum-dried at the same temperature for 6h to obtain CaCl 2 , weigh the CaCl prepared in the previous step 2 About 400g is placed in an alumina crucible, and then placed in a vertical high-temperature react...

Embodiment 3

[0051] First weigh 100 parts of isopropanol, 1.5 parts of polyvinyl alcohol, and 1 part of polyethylene glycol, put them into a ball mill tank, stir properly with a glass rod, and then weigh 10 parts of SiO 2 The powder and 15 parts of graphite powder are properly stirred with a glass rod and started ball milling. After being fully dispersed, take them out and put them in an oven for drying at 120°C. Press them into a 2g round cake with a diameter of 25mm under a pressure of 10MPa. Transfer to a high-temperature oven for sintering at 1300°C, the sintering time is 2.5h-3.5h, and the sintering atmosphere is Ar+6vt%H 2 , in addition, take 550g CaCl 2 2H2O was dried in air at 200°C for 48h and then vacuum-dried at the same temperature for 24h, or air-dried at 300°C for 12h and then vacuum-dried at the same temperature for 6h to obtain CaCl 2 , weigh the CaCl prepared in the previous step 2 About 400g is placed in an alumina crucible, and then placed in a vertical high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com