High-concentration cyanide-containing wastewater resource recovery and intermediate product treatment method

A resource recovery and treatment method technology, which is applied in the field of high-concentration cyanide-containing wastewater resource recovery and intermediate product treatment, can solve the problems of increasing the difficulty and cost of wastewater treatment, affecting the cyanidation process, etc., and achieves significant environmental and social benefits. Effects of low price and reduced environmental risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

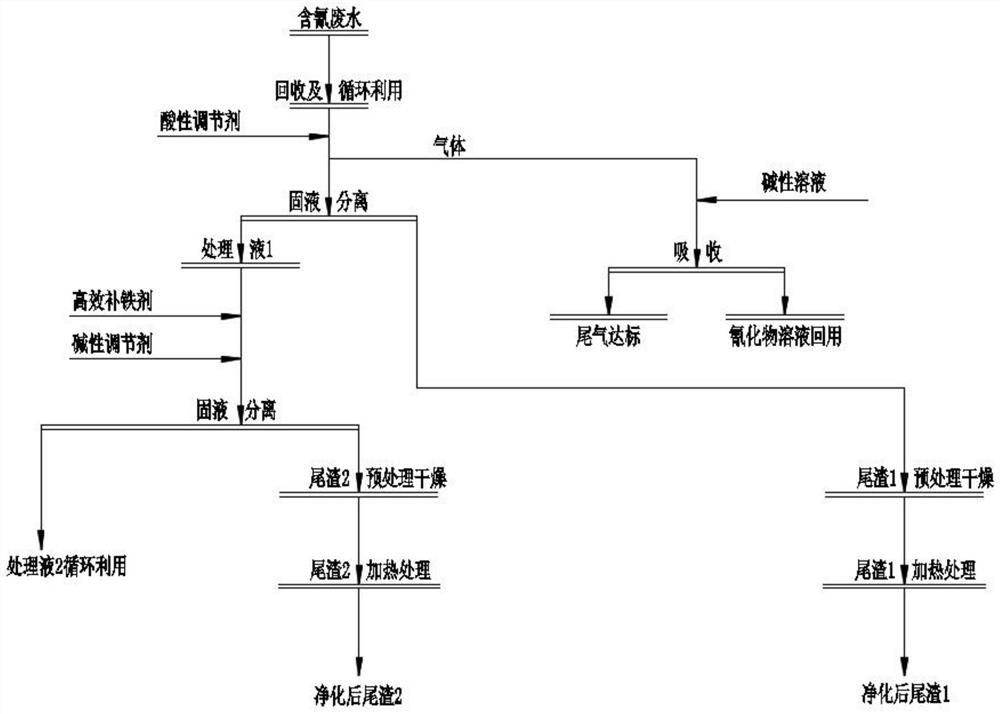

Image

Examples

Embodiment 1

[0028] This cyanide-containing wastewater contains heavy metals such as cyanide, thiocyanate and copper, iron, etc. of higher concentration, wherein the total cyanide concentration is 2540mg / L, the thiocyanate concentration is 4210mg / L, and the copper ion concentration is 830mg / L. The iron ion concentration is 550mg / L, and the treatment steps are as follows:

[0029] (1) Recovery and recycling of valuable substances in wastewater

[0030] 1) adding hydrochloric acid to the cyanide-containing wastewater, fully reacting, adjusting the pH value to 3.5, fully reacting until no sediment is generated, filtering and intercepting the treated wastewater to produce tailings 1 and treatment solution 1;

[0031] 2) The moisture content of tailings 1 is 45%, and the copper content in tailings 1 is 28%;

[0032] 3) Sodium hydroxide solution is used to absorb the gas generated in the reaction process to generate a high-concentration sodium cyanide solution, which is recycled in the cyanide ...

Embodiment 2

[0041] This cyanide-containing wastewater contains heavy metals such as cyanide, thiocyanate and copper, iron, etc. of higher concentration, wherein the total cyanide concentration is 7250mg / L, the thiocyanate concentration is 2800mg / L, and the copper ion concentration is 2100mg / L. Iron ion concentration is 1670mg / L. The processing steps are as follows:

[0042] (1) Recovery and recycling of valuable substances in wastewater

[0043] 1) Add sulfuric acid to the cyanide-containing wastewater, fully react, adjust the pH value to 2.2, fully react until no sediment is generated, and carry out gravity sedimentation to the treated wastewater to produce tailings 1 and treatment solution 1;

[0044] 2) The moisture content of the tailings 1 is 48%, and the copper content in the tailings 1 is 37%;

[0045] 3) The milk of lime solution is used to absorb the gas generated in the reaction process to generate a high-concentration calcium cyanide solution, which is recycled in the cyanide...

Embodiment 3

[0054] The cyanide-containing wastewater contains relatively high concentrations of cyanide and heavy metals such as copper, iron, and zinc, among which the total cyanide concentration is 2480mg / L, the copper ion concentration is 340mg / L, the iron ion concentration is 670mg / L, and the zinc ion concentration is 300mg / L, the processing steps are as follows:

[0055] (1) Recovery and recycling of valuable substances in wastewater

[0056] 1) Add nitric acid to the cyanide-containing wastewater, fully react, adjust the pH value to 4.5, and fully react until no sediment is generated. centrifuging the treated wastewater to produce tailings 1 and treatment liquid 1;

[0057] 2) The moisture content of the tailings 1 is 42%, and the copper content in the tailings 1 is 17%.

[0058] 3) The calcium carbide slag emulsion is used to absorb the gas generated during the reaction process to generate a high-concentration calcium cyanide solution, which is recycled in the cyanide leaching p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com