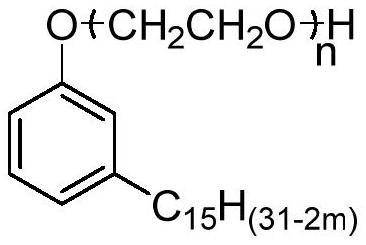

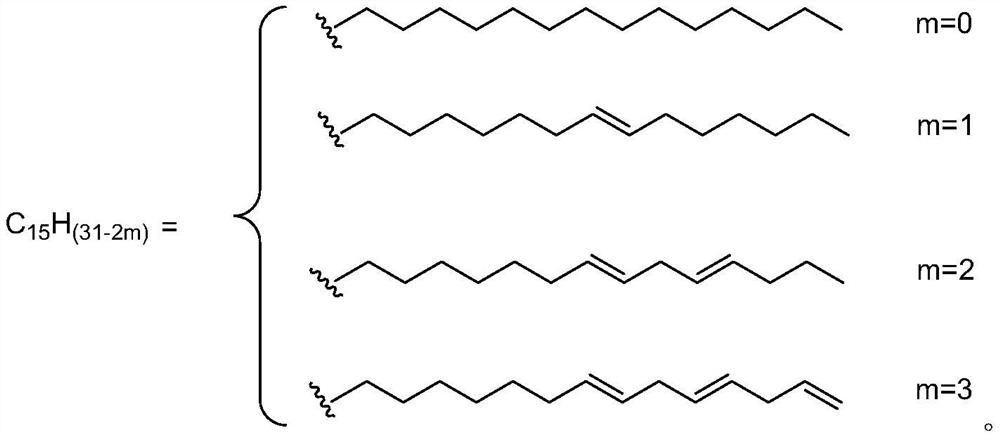

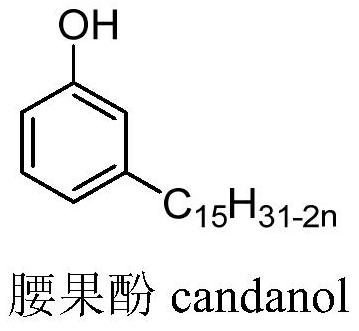

Cardanol polyoxyethylene ether as well as preparation method and application thereof

A cardanol polyoxyethylene ether, cardanol technology is applied in chemical instruments and methods, preparation of detergent mixture compositions, detergent compounding agents, etc. Insufficient research, dark color and other problems, to achieve the effect of strong natural degradation ability, good foam stability and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of cardanol polyoxyethylene ether comprises the following steps:

[0040] Put 234.64g of cardanol into a closed reaction kettle, add 2.94g of potassium hydroxide catalyst, replace the air in the reaction kettle with nitrogen for 3 times, raise the temperature to 100-110°C, keep the temperature, and keep the temperature under a negative vacuum of 0.08MPa. Press down nitrogen gas for dehydration for 30 minutes, start to add ethylene oxide at a temperature of 112.4°C, control the pressure in the reactor between 0.1Mpa and 0.2MPa during the feeding process, and control the reaction temperature at 150-170°C. After 765g of ethylene oxide, the feed intake is all over, continue to react until the pressure in the reactor no longer drops, degassing 10min under 0.1Mpa negative pressure, until the temperature drops to 75°C, add 3g of 30% hydrogen peroxide (according to the obtained cashew nut 0.003 of the theoretical yield of phenol polyoxyethylene ether (add...

Embodiment 2

[0048] The preparation method of cardanol polyoxyethylene ether comprises the following steps:

[0049] Put 197g of cardanol into a closed reaction kettle, add 2.31g of potassium hydroxide catalyst, replace the air in the reaction kettle with nitrogen for 3 times, raise the temperature to 100-110°C, keep the temperature, and keep the temperature under a vacuum of 0.1MPa. Dehydration under high temperature for 30min, and start to add ethylene oxide at a temperature of 120°C. During the feeding process, control the pressure in the reactor between 0.1Mpa and 0.2MPa, and control the reaction temperature at 150-170°C. After adding 574g of epoxy The ethane feeding is all over, continue to react until the pressure in the reactor is no longer reduced, and degas for 10min under a negative pressure of 0.1MPa. When the temperature drops to 65°C, add 2g of 30% hydrogen peroxide (according to the product cardanol polyoxygen 0.005% of the theoretical yield of vinyl ether (add 30% hydrogen p...

Embodiment 3

[0057] The preparation method of cardanol polyoxyethylene ether comprises the following steps:

[0058] Put 213g of cardanol into a closed reaction kettle, add 2.12g of sodium hydroxide catalyst, replace the air in the reaction kettle with nitrogen three times, raise the temperature to 100-110°C, keep the temperature, and under the negative pressure of 0.1MPa vacuum Dehydrate for 30 minutes, start adding ethylene oxide at a temperature of 120°C, control the pressure in the reactor between 0.1Mpa and 0.2MPa during the feeding process, control the reaction temperature at 150-170°C, and add 527g of ethylene oxide After the alkanes, the feeding is all finished, and the reaction is continued until the pressure in the reactor no longer drops, and the degassing is performed under a negative pressure of 0.1Mpa for 10 minutes. When the temperature drops to 80°C, 3.7g of hydrogen peroxide (according to cardanol polyoxyethylene) with a concentration of 30% is added. Add 30% hydrogen pero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com