Preparation method of air-entraining ester polycarboxylate superplasticizer

A technology of ester polycarboxylic acid and water reducer, which is applied in the field of construction admixtures, can solve the problems of increased chemical erosion resistance of concrete, poor concrete workability, and reduced concrete strength, and achieves increased system space and steric effects, Good air-entraining and foam-stabilizing properties, and the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

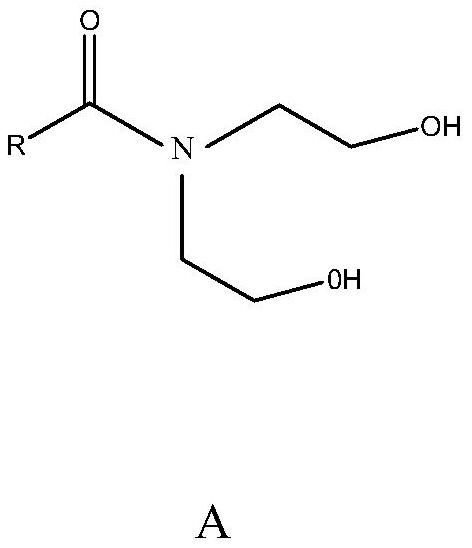

[0039] (1) Preparation of esterification product: In parts by weight, 30 parts of acrylic acid and 100 parts of coconut acid diethanolamide are added to the first reaction vessel for mixing, and under nitrogen conditions, 0.65 parts of cerium sulfate and 2.6 parts of 4-hydroxyl Piperidinol oxygen free radical, and adjust the temperature to 80°C, react for 6h, and obtain the esterification product of monomer with amide, dihydroxyl group and unsaturated acid;

[0040](2) Copolymerization reaction: by weight, earlier the esterification product that 1 part of step (1) makes, 100 parts of polypropylene glycol di(meth)acrylates of molecular weight 2400, 0.3 part of dodecylbenzenesulfonic acid Sodium, 0.6 parts of diethylene glycol monolaurate and 114 parts of water are added to the second reaction vessel and stirred evenly, 1.8 parts of ammonium persulfate and 20 parts of water are mixed evenly in the first dropping device; 2 parts of hydrogen sulfite Sodium, 1 part of thioglycolic ...

Embodiment 2

[0043] (1) Preparation of esterification product: by weight, 61.5 parts of maleic anhydride and 100 parts of cocoic acid diethanolamide were added to the first reaction vessel for mixing, and under nitrogen conditions, 2.42 parts of antimony trioxide, 0.48 Parts of 4-tert-butylcatechol, and adjust the temperature to 90 ° C, react for 5 hours, that is, the esterification product of a monomer with an amide and a double hydroxyl group and an unsaturated acid;

[0044] (2) Copolymerization reaction: by weight, first the esterification product that 2.5 parts of steps (1) make, 100 parts of polyethylene glycol polypropylene glycol di(meth)acrylates of molecular weight 3000, 0.6 part of dodecane Sodium phenylsulfonate, 1.2 parts of diethylene glycol monolaurate and 114 parts of water are added to the second reaction vessel and stirred evenly, and 2 parts of hydrogen peroxide and 20 parts of water are mixed evenly in the first dropping device; 3 times Sodium phosphate, 1.5 parts of me...

Embodiment 3

[0047] (1) Preparation of esterification products: in parts by weight, 60 parts of fumaric acid and 100 parts of cocoic acid diethanolamide are added to the first reaction vessel for mixing, and under nitrogen conditions, 5.6 parts of p-toluenesulfonic acid, 1.3 parts of p-toluenesulfonic acid and 1.3 parts of Parts of methyl hydroquinone, and adjust the temperature to 110 ° C, react for 4 hours, that is, the esterification product of monomers with amide and dihydroxyl groups and unsaturated acids is obtained;

[0048] (2) Copolymerization reaction: in parts by weight, first 3.5 parts of the esterification product obtained in step (1), 100 parts of polytetramethylene glycol monomethacrylate with a molecular weight of 3000, and 0.45 parts of dodecylbenzenesulfonic acid Sodium, 0.9 parts of diethylene glycol monolaurate and 116 parts of water are added to the second reaction vessel and stirred evenly, and 2 parts of hydrogen peroxide and 20 parts of water are mixed evenly in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com