High-temperature-resistant cable internal insulating material and preparation method and application thereof

An internal insulation and high temperature resistant technology, applied in insulators, inorganic insulators, organic insulators, etc., can solve the problem that the resistivity is greatly affected by temperature, the amount of space charge injection and accumulation is small, and inorganic nanoparticles are compatible with polymer matrix materials. It can improve compatibility, reduce the amount of space charge injection and accumulation, and improve the problem of space charge accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

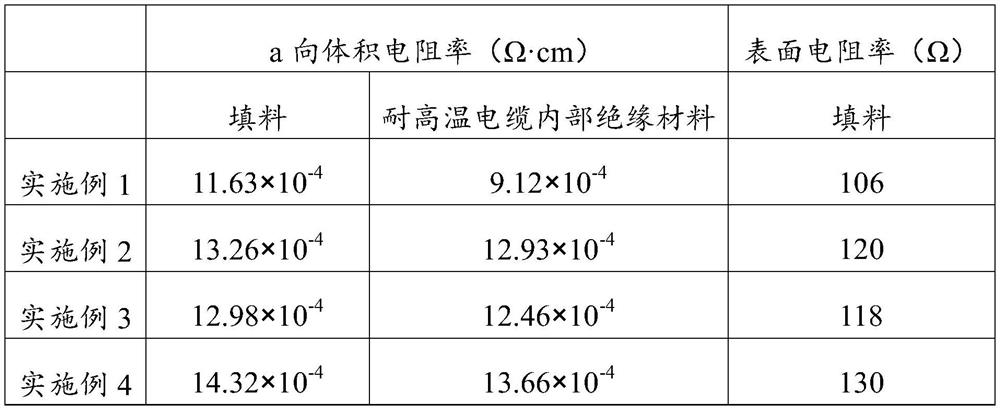

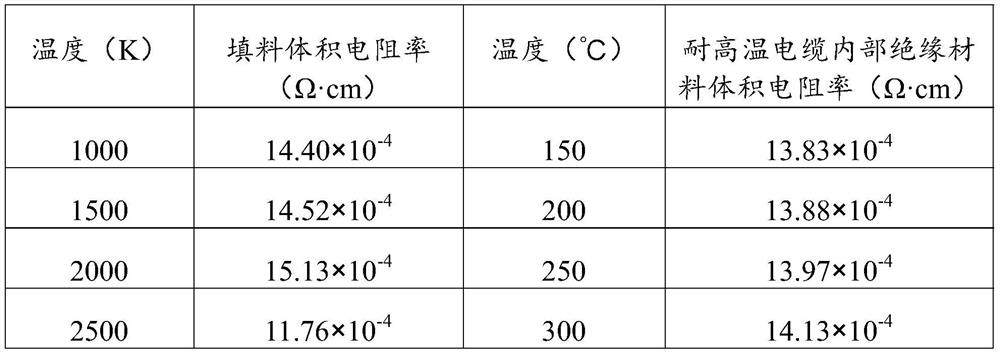

Examples

Embodiment 1

[0031] A preparation method for an internal insulation material of a high temperature resistant cable, comprising the steps of:

[0032] (1) Mix zinc sulfate with sodium hydroxide at a ratio of 1:2, and then add TiO with the amount of zinc sulfate and other substances 2 , after hydrothermal reaction at 180°C for 3.5h in the reactor, washed and dried to constant weight, TiO 2 -ZnO composite material;

[0033] (2) TiO 2 - Fabrication of ZnO composite material supporting substrate: coating epoxy resin on the substrate, the thickness of epoxy resin is 1mm, and then TiO 2 -ZnO composite material is evenly laid on the epoxy resin and dried at room temperature, TiO 2 -ZnO composite with a thickness of 2 mm to obtain TiO 2 - ZnO composite support substrate;

[0034] (3) Coating: The target material of the high-purity pyrolytic graphite target is placed horizontally in the vacuum chamber, so that the center of the target material is located at the center of the circle correspondin...

Embodiment 2

[0040] A preparation method for an internal insulation material of a high temperature resistant cable, comprising the steps of:

[0041] (1) Mix zinc nitrate with sodium hydroxide at a ratio of 1:2, and then add TiO with the amount of zinc nitrate and other substances 2 , after hydrothermal reaction at 200 ° C for 2.5 h in the reactor, washed and dried to constant weight, TiO 2 -ZnO composite material;

[0042] (2)TiO 2 - Fabrication of ZnO composite material supporting substrate: coating epoxy resin on the substrate, the thickness of epoxy resin is 1.5mm, and then TiO 2 -ZnO composite material is evenly laid on the epoxy resin and dried at room temperature, TiO 2 -ZnO composite with a thickness of 2.5 mm to obtain TiO 2 - ZnO composite support substrate;

[0043] (3) Coating: The target material of the high-purity pyrolytic graphite target is placed horizontally in the vacuum chamber, so that the center of the target material is located at the center of the circle corres...

Embodiment 3

[0049] A preparation method for an internal insulation material of a high temperature resistant cable, comprising the steps of:

[0050] (1) Mix zinc sulfate with sodium hydroxide at a ratio of 1:2, and then add TiO with the amount of zinc sulfate and other substances 2 , after hydrothermal reaction at 220°C for 3 hours in the reactor, washed and dried to constant weight, TiO 2 -ZnO composite material;

[0051] (2)TiO 2 - Fabrication of ZnO composite material supporting substrate: coating epoxy resin on the substrate, the thickness of epoxy resin is 1.5mm, and then TiO 2 -ZnO composite material is evenly laid on the epoxy resin and dried at room temperature, TiO 2 -ZnO composite with a thickness of 2.5 mm to obtain TiO 2 - ZnO composite support substrate;

[0052] (3) Coating: The target material of the high-purity pyrolytic graphite target is placed horizontally in the vacuum chamber, so that the center of the target material is located at the center of the circle corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com