Potassium silicate solution for coating electron beam tube fluorescent screen

A potassium silicate solution, electron beam tube technology, applied in the direction of alkali metal silicate coatings, coatings, fireproof coatings, etc., can solve the problems of long drying time, affecting the transparency of the coating solution, yellowing, etc. Curing time, shortening curing time, effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

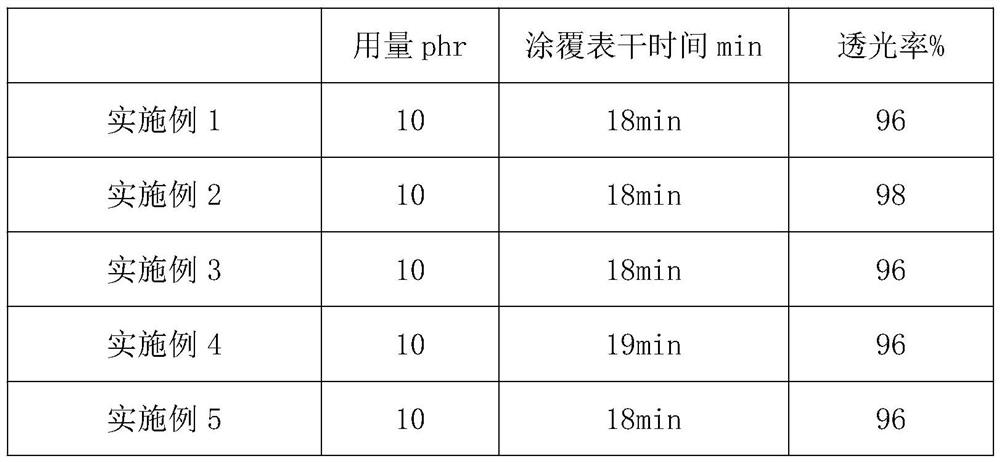

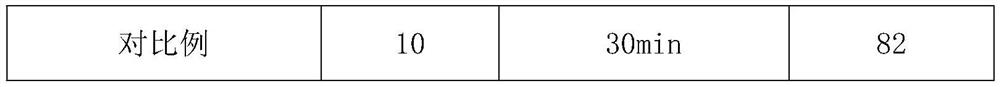

Examples

Embodiment 1

[0016] First prepare modified silica:

[0017] Mix 10 parts of white carbon black with 2 parts of hexamethyldisilazane, 2 parts of dimethyldiethoxysilane and 10 parts of deionized water, and stir for 2 hours at a temperature of 160 ° C to prepare modified white carbon black.

[0018] Then prepare the potassium silicate solution used for electron beam tube fluorescent screen coating:

[0019] Step 1: Mix 26 parts of potassium silicate aqueous solution with a concentration of 15%-20% and 4 parts of modified white carbon black, and add 3 parts of polysiloxane during the mixing process;

[0020] Step 2: Add 10 parts of aromatic solvent to the mixture prepared in Step 1, and add 3 parts of propyltriacetoxysilane at a temperature of 60°C;

[0021] Step 3: Stir the mixture prepared in step 2 continuously. During the stirring process, as the viscosity of the mixture increases continuously, deionized water is dropped into the mixture to make the mixture in a fluid adhesion state suit...

Embodiment 2

[0023] First prepare modified silica:

[0024] Mix 10 parts of white carbon black with 2 parts of hexamethyldisilazane, 2 parts of dimethyldiethoxysilane and 10 parts of deionized water, and stir for 2 hours at a temperature of 160 ° C to prepare modified white carbon black.

[0025] Then prepare the potassium silicate solution used for electron beam tube fluorescent screen coating:

[0026] Step 1: Mix 27 parts of potassium silicate aqueous solution with a concentration of 15%-20% and 5 parts of modified white carbon black, and add 4 parts of polysiloxane during the mixing process;

[0027] Step 2: Add 11 parts of aromatic hydrocarbon solvent to the mixture prepared in Step 1, and add 4 parts of propyltriacetoxysilane at a temperature of 65°C;

[0028] Step 3: Stir the mixture prepared in step 2 continuously. During the stirring process, as the viscosity of the mixture increases continuously, deionized water is dropped into the mixture to make the mixture in a fluid adhesio...

Embodiment 3

[0030] First prepare modified silica:

[0031] Mix 10 parts of white carbon black with 2 parts of hexamethyldisilazane, 2 parts of dimethyldiethoxysilane and 10 parts of deionized water, and stir for 2 hours at a temperature of 160 ° C to prepare modified white carbon black.

[0032] Then prepare the potassium silicate solution used for electron beam tube fluorescent screen coating:

[0033] Step 1: Mix 28 parts of potassium silicate aqueous solution with a concentration of 15%-20% and 6 parts of modified white carbon black, and add 4.5 parts of polysiloxane during the mixing process;

[0034] Step 2: Add 12 parts of aromatic hydrocarbon solvent to the mixture prepared in Step 1, and add 4.5 parts of propyltriacetoxysilane at a temperature of 70°C;

[0035] Step 3: Stir the mixture prepared in step 2 continuously. During the stirring process, as the viscosity of the mixture increases continuously, deionized water is dropped into the mixture to make the mixture in a fluid adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com