Multi-primary-color laser array side-entry type light homogenizing surface light source of liquid crystal display

A liquid crystal display and multi-primary color technology, applied in the field of laser backlight, can solve the problems of uneven intensity distribution, uneven brightness and darkness of the blurred screen, and low brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

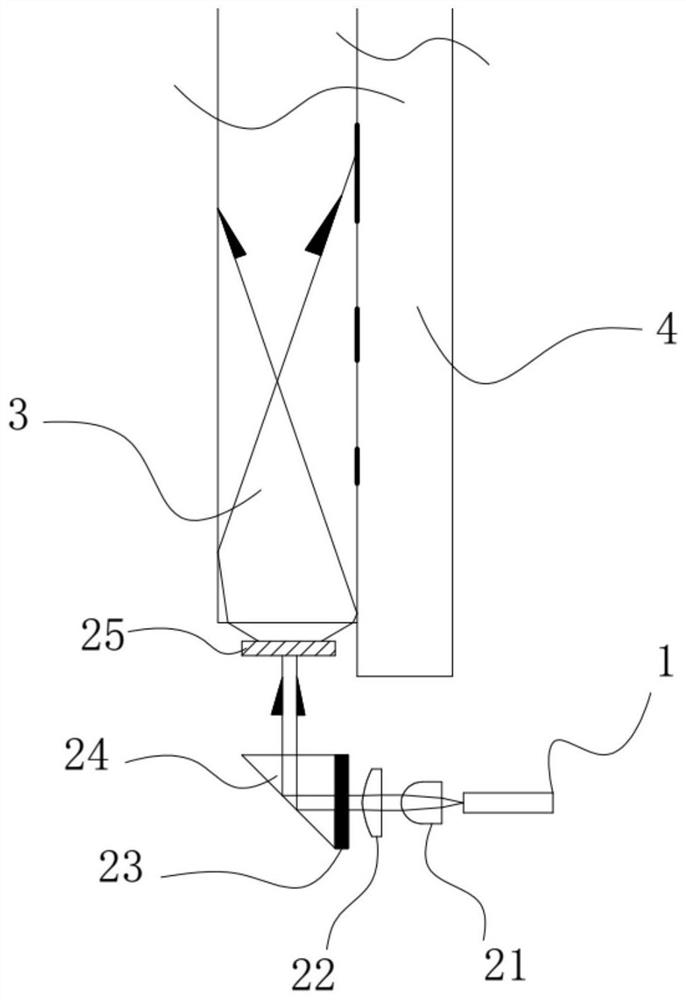

[0036] as attached image 3 As shown, this embodiment discloses a condition and a backlight source for converting a Gaussian laser beam emitted by an end-emitting laser into a top-hat laser beam. Specifically, the end-emitting visible light laser 1 is arranged perpendicular to the light-emitting surface of the light guide plate 3 . A Gaussian laser beam fast-axis compression cylindrical lens 21 and a Gaussian laser beam collimating aspheric mirror 22 are installed at the light exit of the end-emitting visible light laser 1 to focus the Gaussian laser beam into a laser spot with a diameter less than 1.5mm. The laser spot is incident on the refractive micro-optical beam expander 23 arranged on the right-angled surface of the rectangular prism 24 . The refractive micro-optical beam expander 23 expands the laser spot into a flat-top line beam with a uniformity greater than 60%. The length of the flat top-shaped line beam is parallel to the long side or wide side of the light gui...

Embodiment 2

[0039] as attached Figure 4 As shown, this embodiment discloses a condition and a backlight source structure for converting a Gaussian laser beam emitted by an end-emitting laser into a top-hat laser beam.

[0040] Specifically, the end-emitting visible light laser 1 is arranged perpendicular to the light-incident surface of the side of the light guide plate 3 . A Gaussian laser beam collimator 26 is installed at the light exit of the end-emitting visible light laser 1 to focus the Gaussian laser beam into a laser spot with a divergence angle of 4°. The laser spot is incident on the micro-cylindrical lens array 27 , and the arrangement direction of the micro-cylindrical lens array 27 is that the length of the micro-cylindrical lens is parallel to the thickness direction of the light guide plate 3 . After the laser spot passes through the micro-cylindrical lens array 27, it is expanded into an approximately flat-top laser line spot with a fast-axis divergence angle of 150° an...

Embodiment 3

[0044] as attached Figure 5 As shown, this embodiment discloses a liquid crystal display backlight homogenization structure using a chip-type vertical cavity laser (VCSEL) array as a light source.

[0045] The patch-type vertical cavity blue laser 11 , the patch-type vertical cavity red laser 12 and the patch-type vertical cavity green laser 13 together constitute a backlight source for a patch-type three-primary-color laser liquid crystal display.

[0046] The central wavelength of the three-color vertical cavity visible light laser is between 400-490nm for blue light, 500-580nm for green light, and 600-680nm for red light, and the spectral half-peak width of the three-color vertical cavity visible light laser is less than 10nm.

[0047] Specifically, several patch-type vertical cavity blue lasers 11, several patch-type vertical cavity red lasers 12, and several patch-type vertical cavity green lasers 13 are alternately arranged on the heat-conducting PCB board. A Gaussian ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com