Application of oil shale as feed additive

A feed additive, oil mother shale technology, applied in the application, animal feed, additional food elements, etc., to achieve the effect of saving grain, enhancing immunity, and saving grain for feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

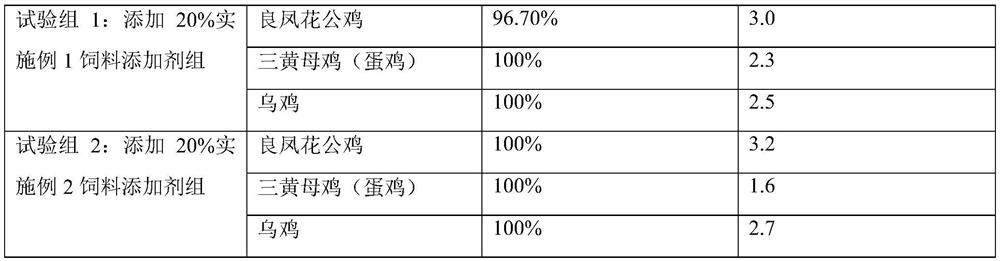

Examples

Embodiment 1

[0028] The feed additive in this embodiment is composed of 100% kerogen shale.

[0029] The granulation of above-mentioned feed additive comprises the following steps:

[0030] Step 1: Naturally air-dry the kerogen shale, crush it, and Raymond mill it into 200 mesh to obtain kerogen shale powder;

[0031] Step 2: Stir the kerogen shale powder evenly with a double-shaft horizontal mixer, enter the disc granulator for granulation, and spray water during granulation.

[0032] Step 3: After drying, cooling, and sieving, two grades of particles of 1.2-2mm and 2-4mm are obtained. After the finished product is packaged, the small particles of 1.2-2mm are used for chickens, pigs, cattle, sheep, etc., and the large particles of 2-4mm are supplied Adult chickens, ducks and geese are edible.

Embodiment 2

[0034] The feed additive of the present embodiment is made up of the raw material of following percentage by weight:

[0035] 78% kerogen shale, 20% calcite, 2% feed grade trace elements.

[0036] The granulation of above-mentioned feed additive comprises the following steps:

[0037] Step 1: natural air-drying, crushing, and Raymond milling of kerogen shale to obtain kerogen shale powder; crushing calcite and Raymond grinding to 200 mesh to obtain calcite powder;

[0038] Step 2: Stir the kerogen shale powder and calcite powder evenly with a double-shaft horizontal mixer, enter the disc granulator for granulation, and spray water during granulation, and add feed-grade trace elements.

[0039] Step 3: After drying, cooling, and sieving, two grades of particles of 1.2-2mm and 2-4mm are obtained. After the finished product is packaged, the small particles of 1.2-2mm are used for chickens, pigs, cattle, sheep, etc., and the large particles of 2-4mm are supplied Adult chickens, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com