Cement kiln tail waste gas colored smoke plume treatment system and method

A technology for cement kiln and kiln tail, which is applied in the field of non-ferrous plume treatment system of kiln tail waste gas of cement kiln, can solve the problems of limited heating range, low temperature, insufficient dry flue gas emission, etc., to solve environmental protection problems and facilitate maintenance. , the effect of completely eliminating visual pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

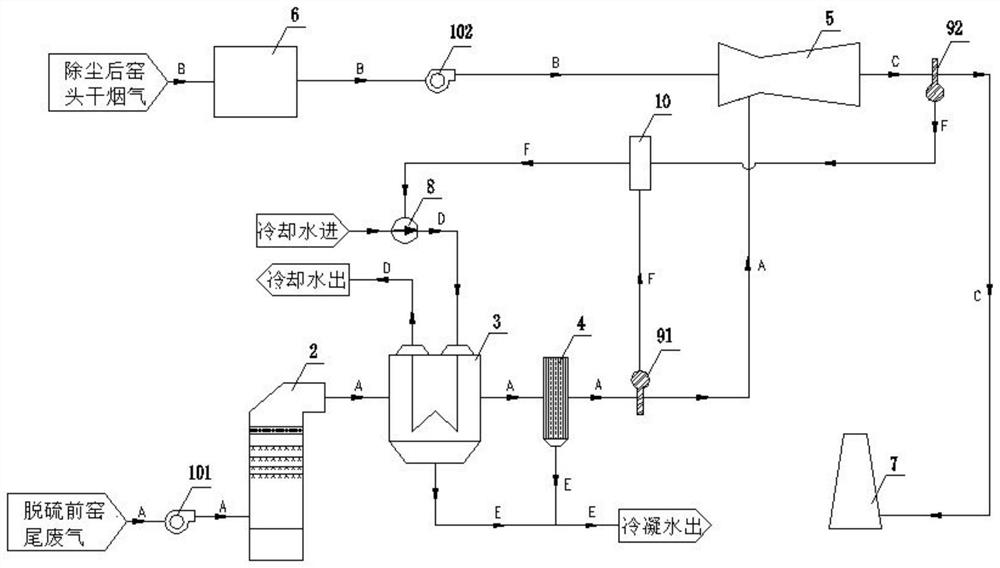

[0038] refer tofigure 1 , a cement kiln kiln exhaust gas colored plume treatment system, comprising a first exhaust fan 101, a second exhaust fan 102, a desulfurization tower 2, a condensation system, a swirl mixer 5 and a waste heat boiler 6, the first exhaust fan 101. The desulfurization tower 2, the condensing system and the swirl mixer 5 are sequentially connected through the kiln tail exhaust gas pipeline A, and the waste heat boiler 6, the second exhaust fan 102 and the swirl mixer 5 are sequentially connected through the kiln head flue gas pipeline B, The cement kiln exhaust gas before desulfurization enters the first exhaust fan 101, the desulfurization tower 2, the condensing system and the swirl mixer 5 through the kiln exhaust pipeline A in sequence, and the dry flue gas from the cement kiln head enters the waste heat through the kiln flue gas pipeline B in sequence The boiler 6, the second exhaust fan 102 and the swirl mixer 5, the outlet of the swirl mixer 5 is con...

Embodiment 2

[0057] refer to figure 1 , this embodiment is a modification based on Embodiment 1, specifically: the heat exchange tubes of the flue condenser 3 in Embodiment 1 are made of fluoroplastics, the diameter of the tube is 10-14 mm, and the wall thickness is 1 mm. U-shaped arrangement; the flue condenser 3 in this embodiment can be replaced by a titanium tube with a diameter of not less than 25mm and a wall thickness of 1-1.5mm. The heat exchange tubes are arranged in an S-shaped arrangement, and metal finned tubes can also be used Instead, the pipe diameter is not less than 38mm, the wall thickness is 3-5mm, and the heat exchange tubes are arranged in an S shape.

[0058] The specific work flow of this embodiment is consistent with that of Embodiment 1.

Embodiment 3

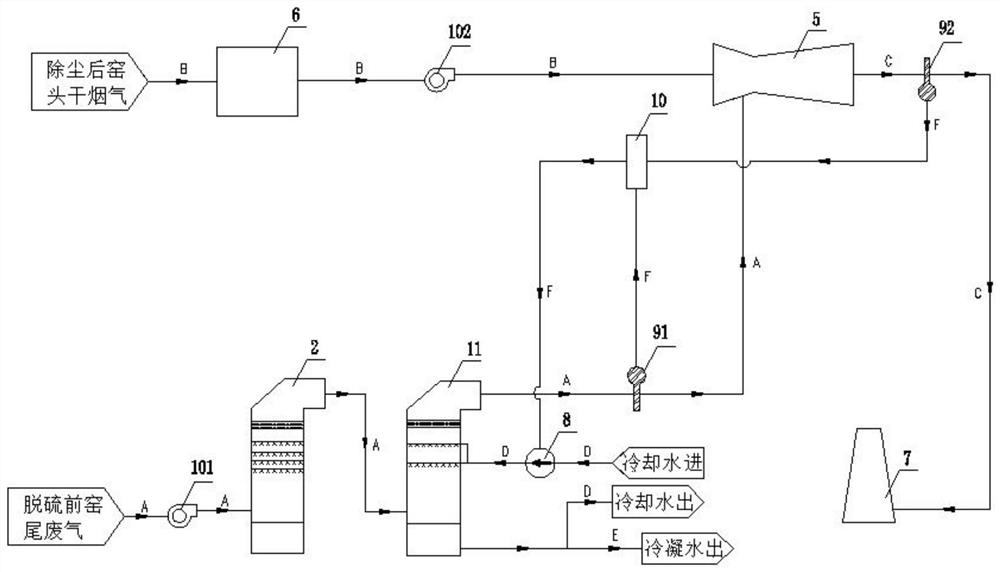

[0060] refer to figure 2 , this embodiment is a change based on embodiment 1, specifically: the flue condenser 3 in embodiment 1 is a partitioned wall heat exchanger, and this embodiment is replaced by a spray tower 11, and embodiment 1 is cancelled. The flue demister 4 in the present embodiment has its own demister on the top floor of the spray tower 11.

[0061] Specifically, the condensing system includes a cooling water pump 8 and a spray tower 11. The top of the desulfurization tower 2 is connected to the bottom of the spray tower 11 through the kiln tail waste gas pipeline A, and the top of the spray tower 11 is connected to the bottom of the spray tower 11 through the kiln tail. The exhaust gas pipeline A is connected to the swirl mixer 5; the spray layer of the spray tower 11 is provided with a cold medium inlet, connected to the water inlet side of the cooling water pipeline D, and a cooling water pump 8 is set, and the spray tower 11 The bottom of the cooling mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com