High-temperature water slag flushing dead steam energy-saving water collection and pollutant treatment system and method

A technology for high-temperature water and pollutants, applied in water/sewage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., can solve equipment corrosion, low heat exchange efficiency of air coolers, and incomplete treatment scope and other issues, to achieve the effect of reducing pollutant discharge, preventing acid corrosion, and solving environmental protection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

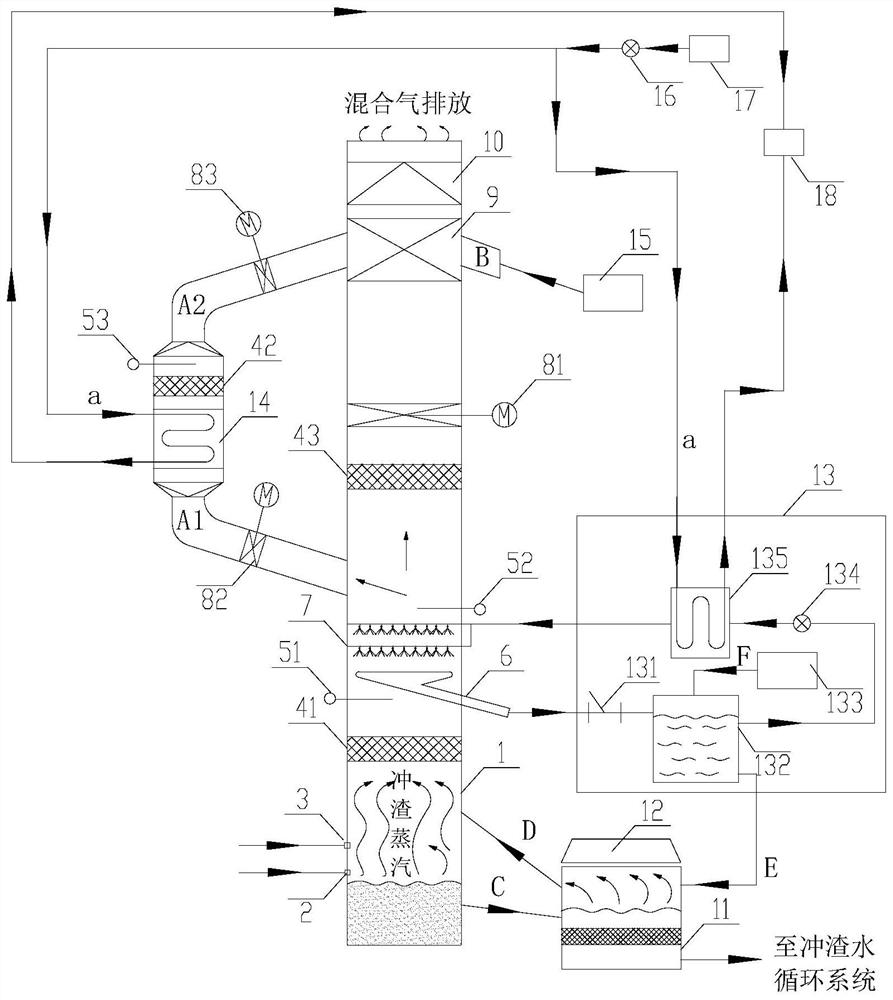

Embodiment 1

[0041] refer to figure 1 , a high-temperature water washing slag lack of steam energy-saving water collection and pollutant treatment system includes a high-altitude granulation tower 1, a slag washing water inlet 2 arranged on the tower body of the high-altitude granulation tower 1 sequentially from bottom to top, High temperature slag inlet 3, spray device 7, mixed air heating area 9, mixed air induced fan 10; also includes slag flushing pool 11, spray water condensate treatment unit 13, exhaust steam bypass condenser 14, gas heat source unit 15 and the second demister 42; the spray water condensate treatment unit 13 is connected to the spray device 7, and provides spray water for the spray device 7 through the spray water pipeline, and the slag washing pool 11 passes through the slag water ditch C is connected to the tower wall at the bottom of the high-altitude granulation tower 1, and the top side wall of the slag washing tank 11 is connected to the tower wall of the high...

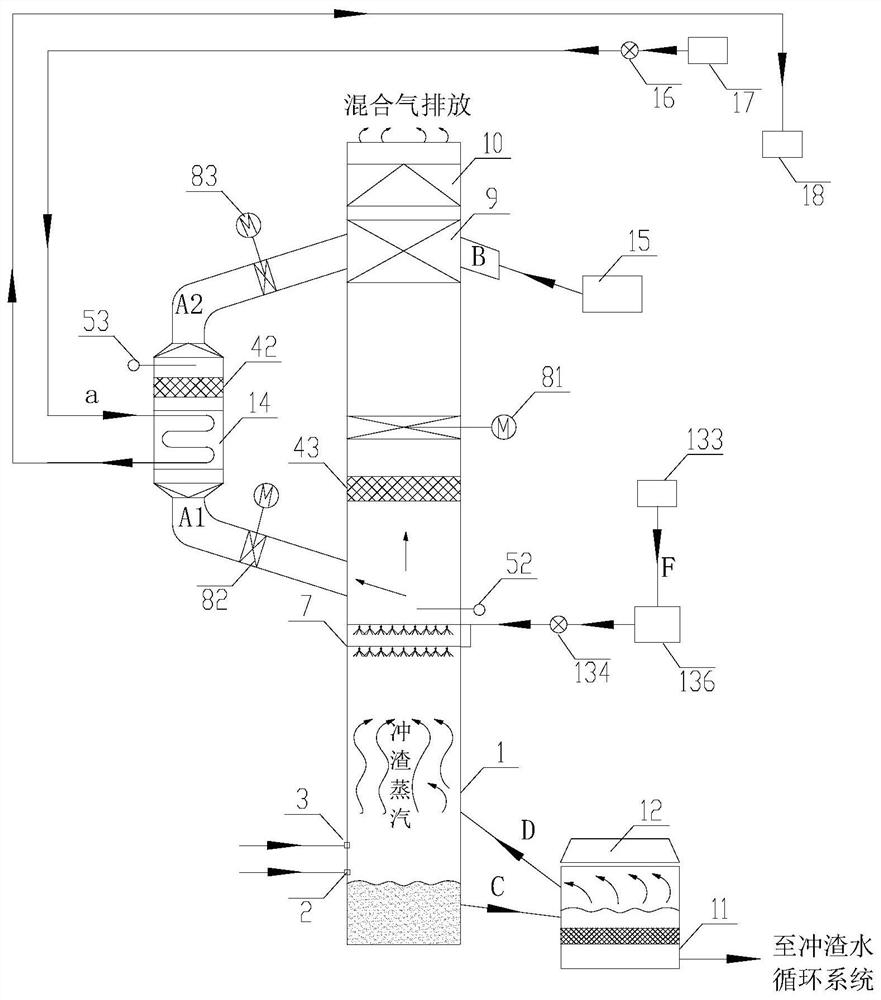

Embodiment 2

[0062] refer to figure 2 , the governance system of this embodiment makes the following changes on the basis of Embodiment 1:

[0063] First, cancel the first demister 41, the first temperature-hygrometer 51, and the liquid collection tray 6 in Embodiment 1;

[0064] Second, the spray water condensate treatment unit 13 of this embodiment replaces the spray water condensate treatment unit 13 of Embodiment 1 with a conditioning device 133 , a circulation pump 134 and a second water supply tank 136 .

[0065] Specifically, the spray water condensate treatment unit 13 includes a conditioning device 133, a circulating pump 134, and a second replenishing water tank 136, and the second replenishing water tank 136 is connected to the water inlet of the spraying device 7 through the circulating pump 134, for The spraying device 7 provides spraying water, and the tempering device 133 is connected to the top of the second supplementary water tank 136 through the alkali agent pipeline F...

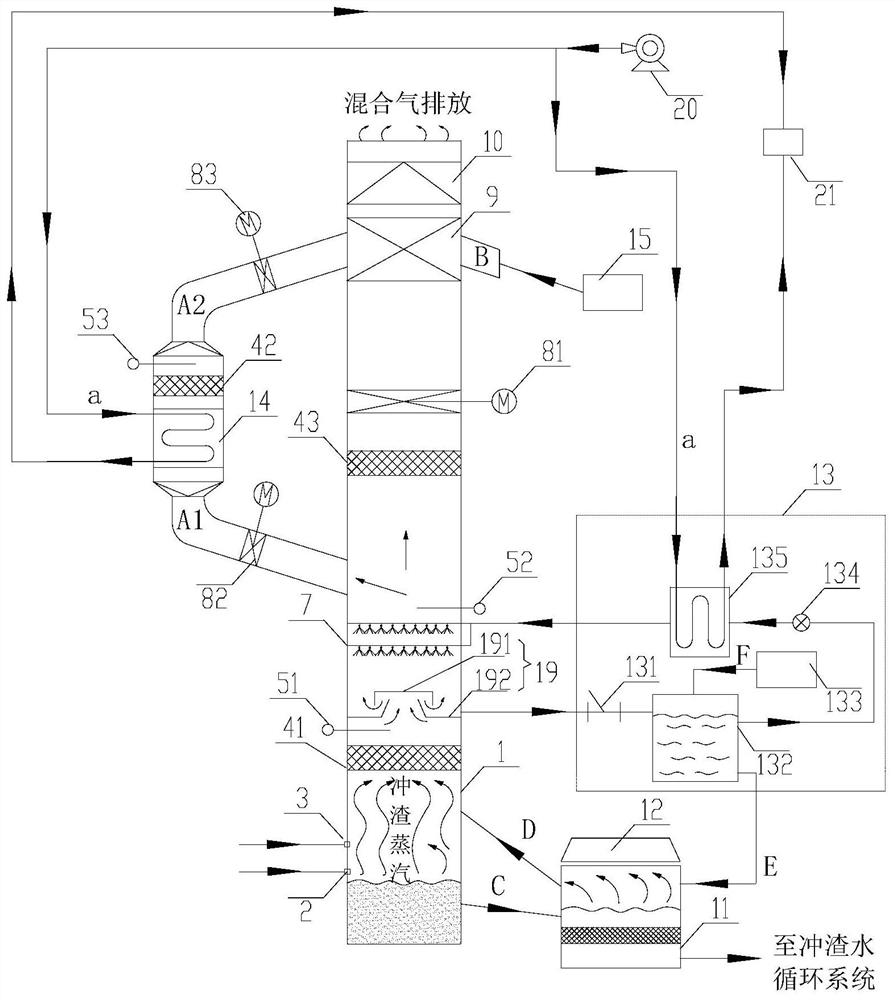

Embodiment 3

[0076] refer to image 3 , the governance system of this embodiment makes the following changes on the basis of Embodiment 1:

[0077] First, the spray water and condensed water collection device in embodiment 1 is the liquid collection tray 6, which is replaced by the rising steam liquid collection tray 19 in this embodiment;

[0078] Specifically, the steam and liquid collecting tray 19 includes a central baffle plate 191 and a lower tray 192, the outer ring of the lower tray 192 is installed on the inner wall of the high-altitude granulation tower 1, and the center of the lower tray 192 has a The exhaust cylinder has a circular truncated cross-section that gradually decreases from bottom to top. The exhaust cylinder has an exhaust channel for the slag flushing steam to migrate upward. The central baffle plate 191 is located at the exhaust Directly above the channel, the outer ring of the central baffle plate 191 has a guide edge extending downward, and the outer diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com