High-flux super-resolution focal spot generation device based on optical fibers

A generation device and super-resolution technology, applied in the field of optical engineering, can solve problems such as low throughput of systems and technical solutions, achieve the effects of reducing device cost and system space, improving processing speed and imaging speed, and compact system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

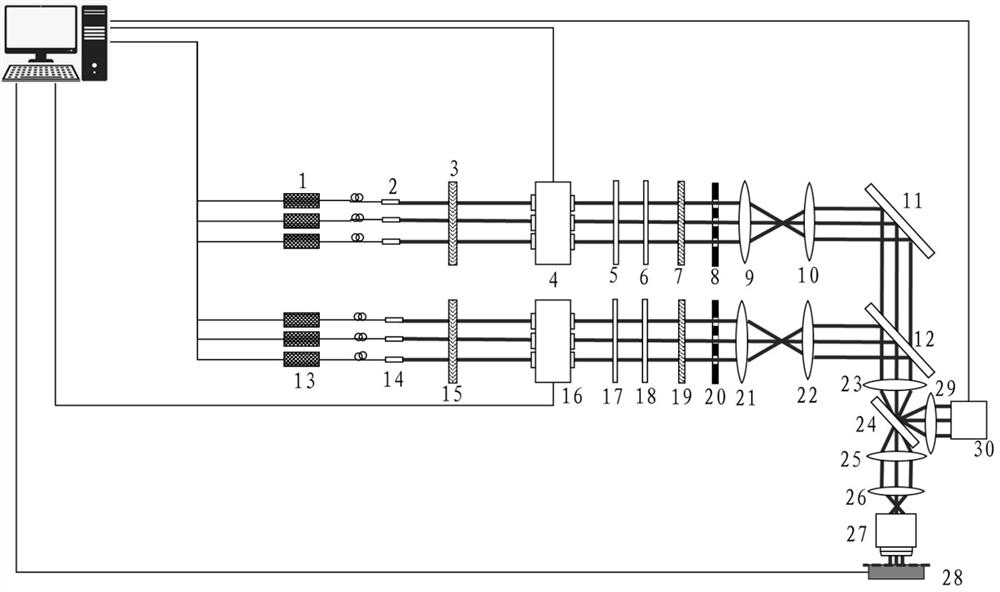

[0017] figure 1 Only 3-way light is taken as an example and only the chief light of each light is drawn for illustration, the actual number and arrangement are not limited.

[0018] Such as figure 1 As shown, the present invention is a fiber-based high-throughput super-resolution focal spot generation device, including a suppressed light laser array 1, a suppressed vortex fiber array 2, a first microlens array 3, and a first multi-channel acousto-optic modulator 4. The first half-wave plate 5, the first quarter-wave plate 6, the second microlens array 7, the first pinhole array 8, the first lens 9, the second lens 10, the mirror 11, the dichroic mirror 12. Excitation laser array 13, excitation optical fiber array 14, third microlens array 15, second multi-channel acousto-optic modulator 16, second half-wave plate 17, second quarter-wave plate 18, fourth Micro-lens array 19, the second aperture array 20, the third lens 21, the fourth lens 22, the fifth lens 23, the half mirro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com