Rock wool board production line

A production line, rock wool board technology, applied in the direction of processing discharged materials, lighting and heating equipment, furnace components, etc., can solve the problems of rock wool compressive strength decline, inconvenient rock wool board placement, rock wool board low work efficiency and other problems , to achieve the effect of improving compressive strength, improving convenience and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

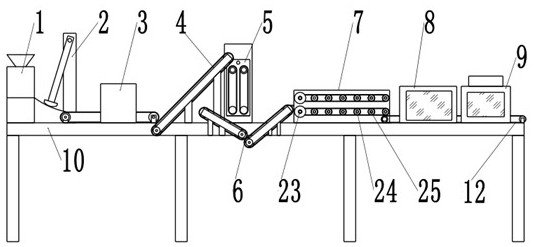

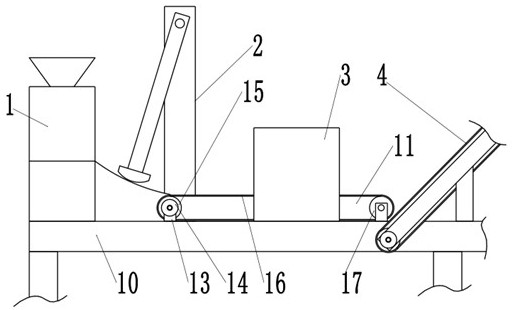

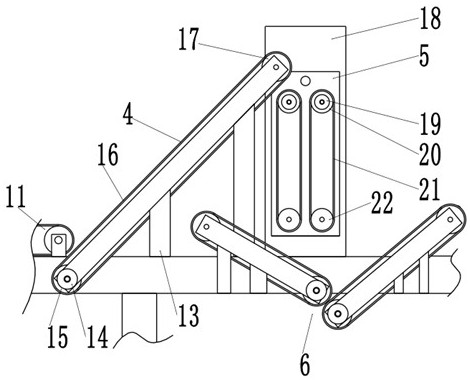

[0036] A rock wool board production line, including a workbench 10, the top of the workbench 10 is fixed with a cotton collector 1, a pendulum cotton cloth machine 2, a forming machine 3, a first conveying mechanism 4, a vertical thread pendulum cotton cloth machine 5, The second conveying mechanism 6, the folding mechanism 7 and the curing furnace 8, the top end of the workbench 10 is equipped with a cooling box 9 through bolts, and the top of the workbench 10 is equipped with a third conveying mechanism 11 and a fourth conveying mechanism 12 through bolts, One side of folding mechanism 7 is equipped with servo motor two 23, and servo motor two 23 drives some gear discs 25 by chain 24, and the output end of servo motor two 23 and one side of discount mechanism 7 are all equipped with gear discs 25, gears The rotation of the disk 25 can drive the folding roller 26 to rotate. The outer wall of the gear disk 25 is meshed with a chain 24, and one side of the gear disk 25 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com