Manual processing method of crystal glass artware

A technology of crystal glass and processing methods, which is applied in the direction of blown glass, glass forming, glass manufacturing equipment, etc., and can solve problems such as scrapped handicrafts, large vital capacity, and high work pressure of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

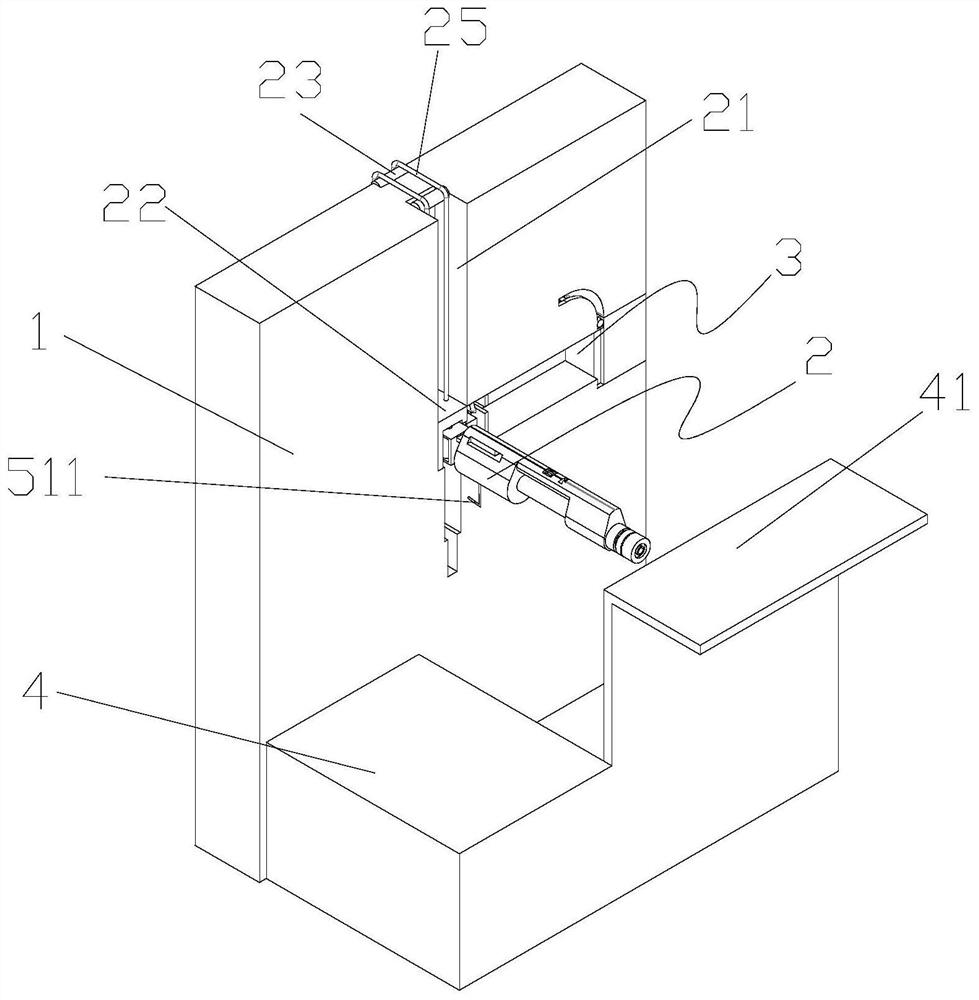

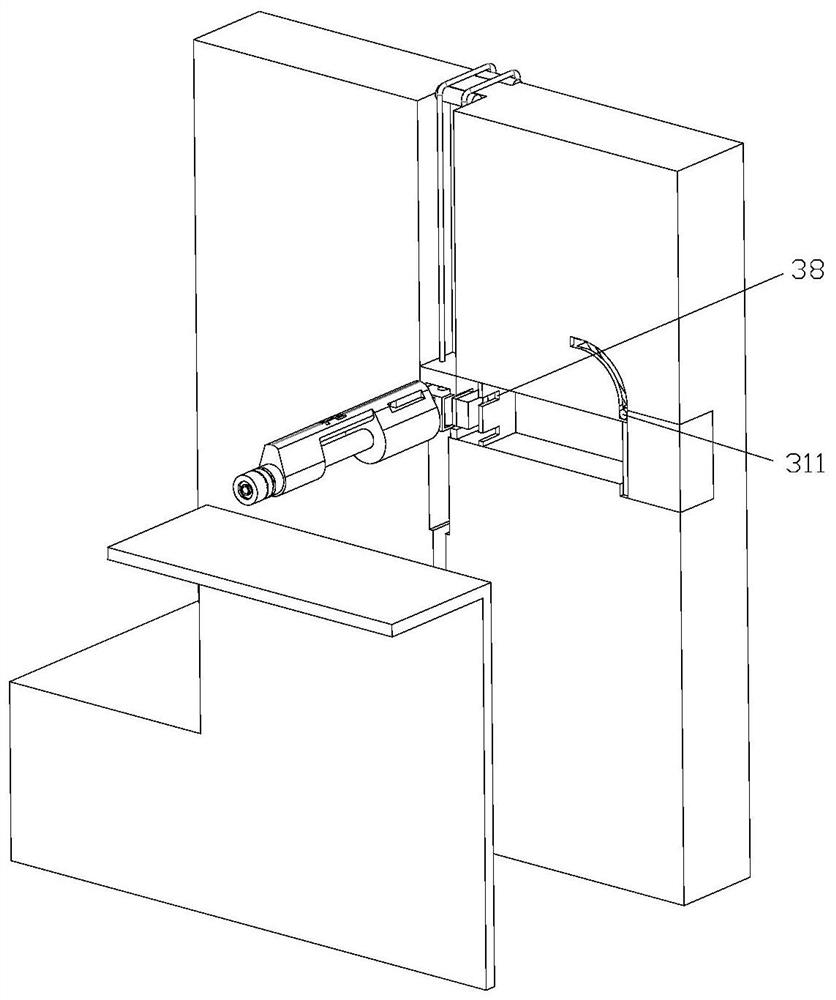

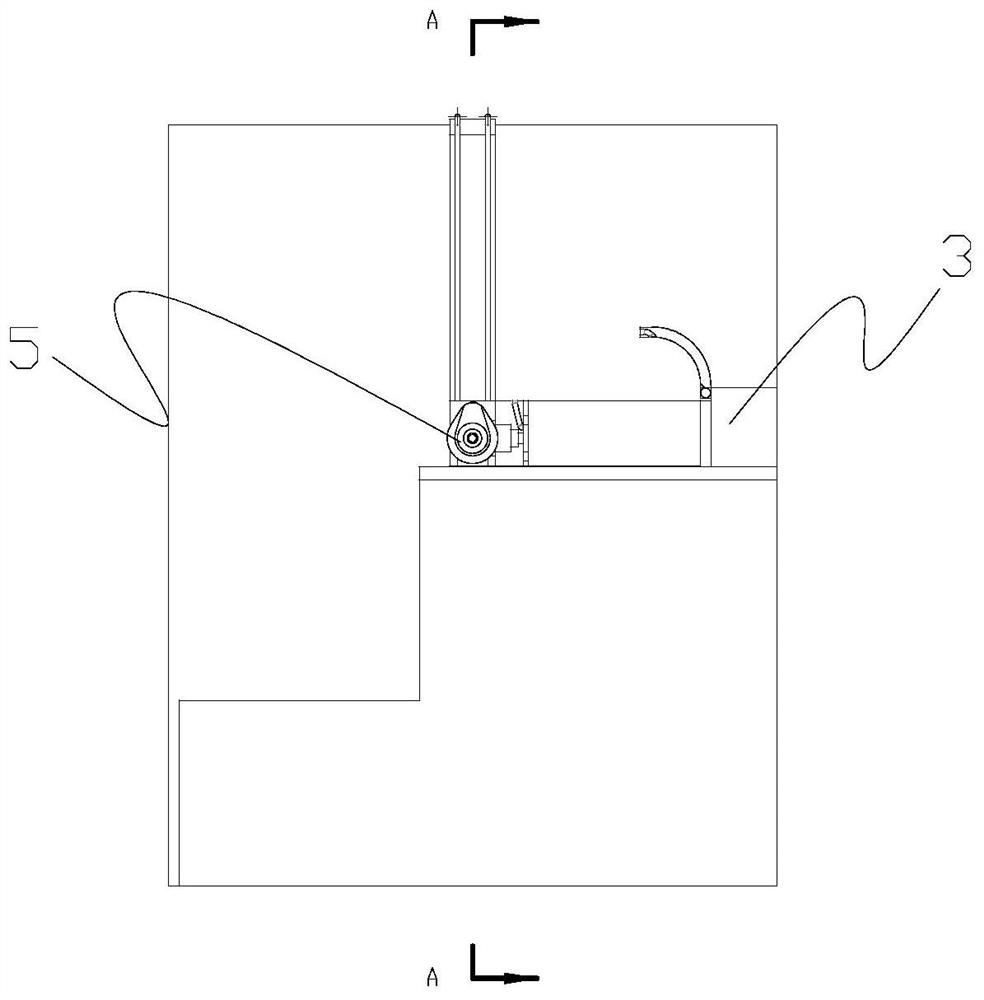

Image

Examples

Embodiment 1

[0049] A method for manual processing of crystal glass handicrafts, characterized in that: it is composed of the following components by weight: nano silicon powder 90kg, potassium nitrate 2kg, zirconium silicate 2kg, calcite 15kg, sodium fluoride 1kg, Yuanming powder 1kg, sodium nitrate 1kg, kyanite 1kg, rare earth oxide 0.012kg, nano selenium powder 0.008kg, nano cobalt powder 0.065kg, cellulose 0.0038kg, phosphotungstic acid 0.1kg. The process steps are as follows (1) Weigh potassium nitrate, zirconium silicate, calcite, sodium fluoride, Yuanming powder, sodium nitrate, kyanite, rare earth oxide and phosphotungstic acid according to the weight ratio, and send them into a mixer to mix evenly, Then send it into an ultrasonic disperser for ultrasonic dispersion for 1 hour to obtain a mixture for later use; (2) put the ultrasonically dispersed mixture into a ball mill, add nano silicon powder, nano selenium powder, nano cobalt powder and cellulose to obtain a The agate ball is ...

Embodiment 2

[0051] A method for manual processing of crystal glass handicrafts, characterized in that: it is composed of the following components by weight: 110kg of nano-silicon powder, 3kg of potassium nitrate, 2.5kg of zirconium silicate, 20kg of calcite, 2kg of sodium fluoride, 2kg of Yuanming powder, 2kg of nitric acid Sodium 1.5kg, kyanite 1.5kg, rare earth oxide 0.05kg, nano selenium powder 0.03kg, nano cobalt powder 0.09kg, cellulose 0.058kg, phosphotungstic acid 1kg. The process steps are as follows (1) Weigh potassium nitrate, zirconium silicate, calcite, sodium fluoride, Yuanming powder, sodium nitrate, kyanite, rare earth oxide and phosphotungstic acid according to the weight ratio, and send them into a mixer to mix evenly, Then send it into an ultrasonic disperser for ultrasonic dispersion for 1 hour to obtain a mixture for later use; (2) put the ultrasonically dispersed mixture into a ball mill, add nano silicon powder, nano selenium powder, nano cobalt powder and cellulose t...

Embodiment 3

[0053] A method for manual processing of crystal glass handicrafts is characterized in that: it is composed of the following components by weight: 100kg of nano-silica powder, 2.5kg of potassium nitrate, 2.2kg of zirconium silicate, 17kg of calcite, 1.5kg of sodium fluoride, and 1.5kg of Yuanming powder. kg, sodium nitrate 1.2kg, kyanite 1.2kg, rare earth oxide 0.032kg, nano selenium powder 0.019kg, nano cobalt powder 0.075kg, cellulose 0.048kg, phosphotungstic acid 0.5kg. The process steps are as follows (1) Weigh potassium nitrate, zirconium silicate, calcite, sodium fluoride, Yuanming powder, sodium nitrate, kyanite, rare earth oxide and phosphotungstic acid according to the weight ratio, and send them into a mixer to mix evenly, Then send it into an ultrasonic disperser for ultrasonic dispersion for 1 hour to obtain a mixture for later use; (2) put the ultrasonically dispersed mixture into a ball mill, add nano silicon powder, nano selenium powder, nano cobalt powder and ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com