Capillary aluminum tube for high-speed flow of gallium-based liquid metal containing oxide layer and preparation method thereof

A liquid metal, high-speed flow technology, applied in the field of microelectronics, can solve problems such as failure of aluminum-based heat sink components, catastrophic accidents, and difficulty in normal flow of liquid metal, so as to prevent embrittlement reactions and broaden the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

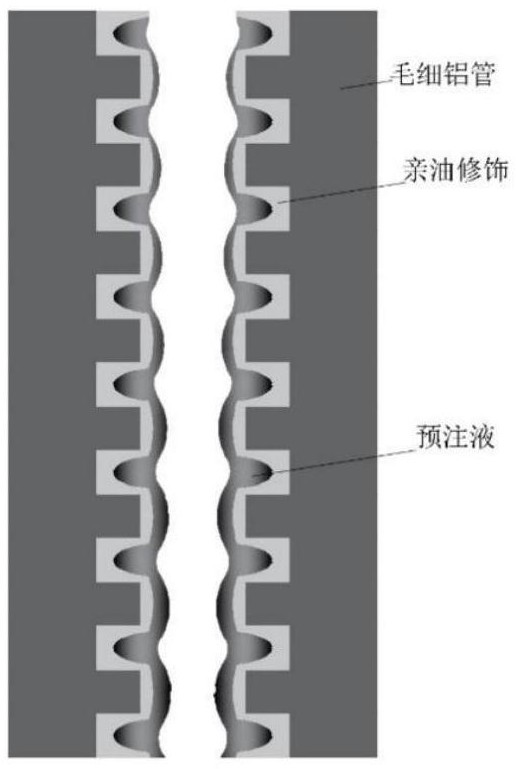

[0055] A preparation method of a capillary aluminum tube capable of high-speed flow of gallium-based liquid metal containing an oxide layer, comprising the following steps:

[0056] (1) Pretreatment of capillary aluminum tube

[0057] After filling the capillary aluminum tube with acetone, seal it, ultrasonically clean it for 5-10min, and the ultrasonic frequency is 40-60kHz; after pouring out the acetone, inject alcohol, seal it, and ultrasonically clean it for 5-20min, and the ultrasonic frequency is 40-60kHz; after pouring out the alcohol Inject deionized water, seal, ultrasonically clean for 5-15min, and the ultrasonic frequency is 40-60kHz.

[0058] The above-mentioned cleaned capillary aluminum tube is placed in an oven at 60-150° C. for drying treatment, the drying time is 20-120 min, and it is sealed for future use.

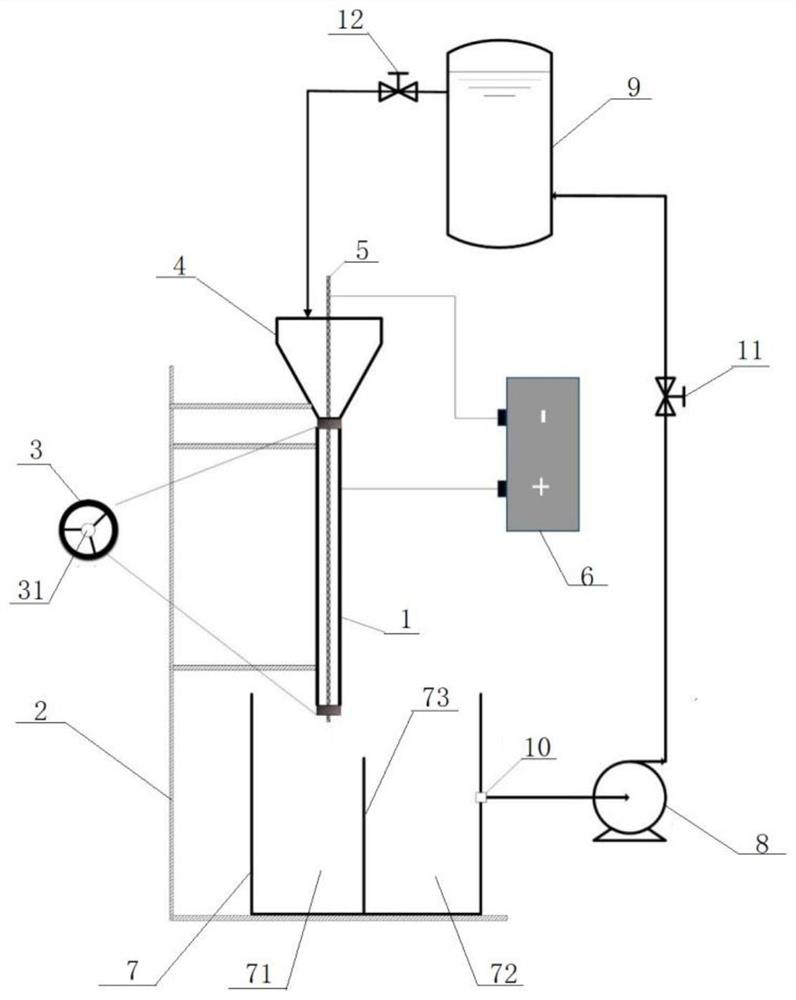

[0059] (2) Electrochemical machining of the inner wall of the capillary aluminum tube

[0060] The inner wall of the capillary aluminum tube is electro...

Embodiment 1

[0084] (1) Pretreatment of capillary aluminum tube

[0085] After the capillary aluminum tube with an inner diameter of 200 μm was filled with acetone, sealed, ultrasonically cleaned for 6 minutes, and the ultrasonic frequency was 40 kHz; after pouring out the acetone, poured alcohol, sealed, and ultrasonically cleaned for 6 minutes, and the ultrasonic frequency was 40 kHz; poured out the alcohol and injected deionized water. , sealed, ultrasonic cleaning 8min, ultrasonic frequency is 40kHz. The above-mentioned cleaned capillary aluminum tube was placed in an oven at 60° C. for drying treatment, and the drying time was 30 min. Save for backup.

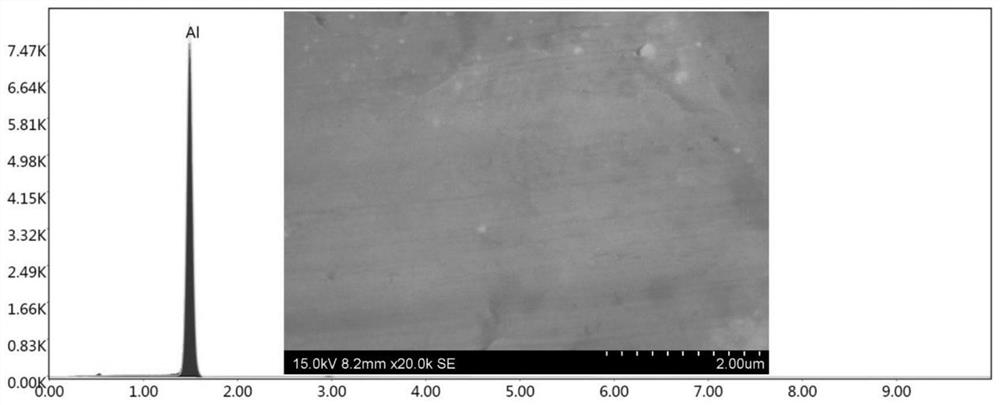

[0086] The surface microstructure and element analysis of the inner wall of the capillary aluminum tube after surface cleaning are as follows: image 3 As shown, the XRD pattern is as Figure 4 The corresponding obtained element amounts are shown in Table 1. from image 3 It can be seen from the microstructure of the inner wall of...

Embodiment 2

[0109] (1) Pretreatment of capillary aluminum tube

[0110] A capillary aluminum tube with an inner diameter of 500 μm was used, and the pretreatment parameters and process were the same as those in Example 1.

[0111] (2) Electrochemical machining of the inner wall of the capillary aluminum tube

[0112] The electrochemical machining device is the same as that of Example 1.

[0113] The concentration of the electrolyte solution selected during electrochemical machining is 0.25mol / L NaCl solution, and the current density is 250mA / cm 2 , the reaction temperature was 25 °C, and the reaction time was 15 min. After the reaction, anhydrous ethanol was injected into the capillary aluminum tube, sealed, and ultrasonically cleaned for 5 minutes. 8min, the ultrasonic frequency is 40kHz. Finally, the capillary aluminum tube was dried in a 60°C oven for 25 min.

[0114] (3) Anodizing processing of the inner wall of the capillary aluminum tube

[0115] The electrolyte solution is a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com