Modified diaphragm for lithium-sulfur battery and preparation method thereof

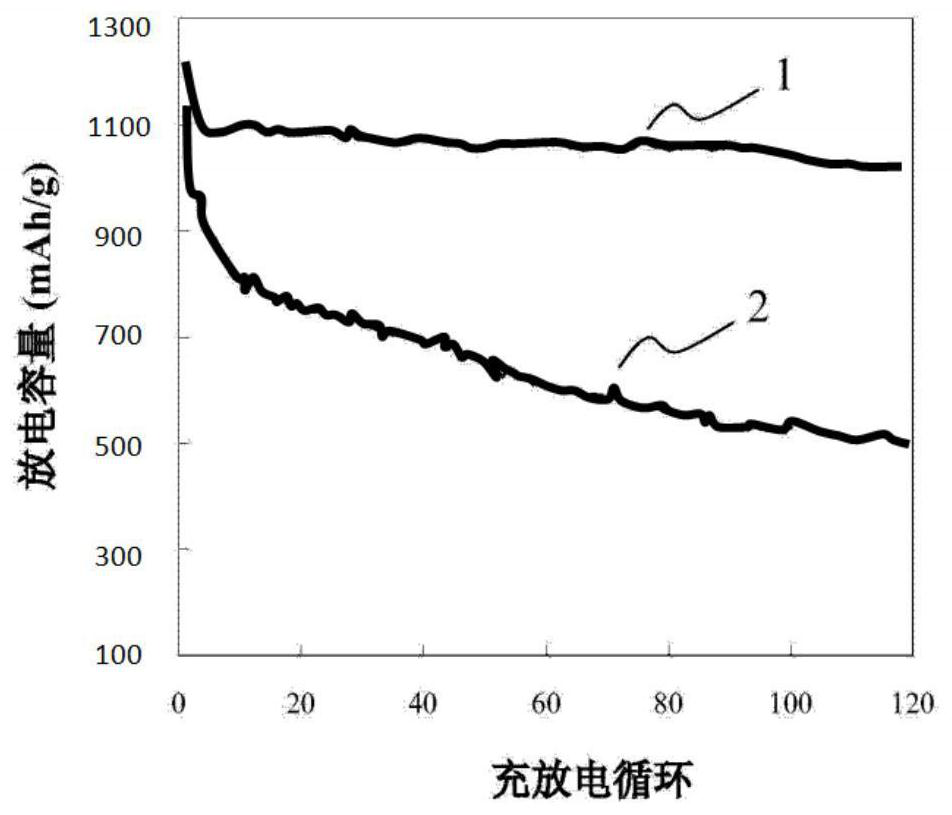

A lithium-sulfur battery and modification technology, which is applied in the direction of lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of sulfur positive electrode volume change, large polarization resistance, and low utilization rate of positive electrode materials, so as to promote Transmission, the effect of reducing interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention also provides a preparation method of the modified diaphragm for the lithium-sulfur battery, comprising the following steps:

[0037] (1) Preparation of porous carbon materials:

[0038] Clean 10 g of melamine sponge with absolute ethanol and deionized water, after drying, carbonize the melamine sponge at 500° C. for 6 hours under a nitrogen protective atmosphere, and obtain a carbon sponge after cooling;

[0039] (2) Preparation of porous graphene oxide:

[0040] Graphene oxide was ultrasonically dispersed in a 10M sodium hydroxide solution, and then refluxed at 100°C for 10 hours; the obtained samples were washed with absolute ethanol and deionized water, filtered three times, and then dried;

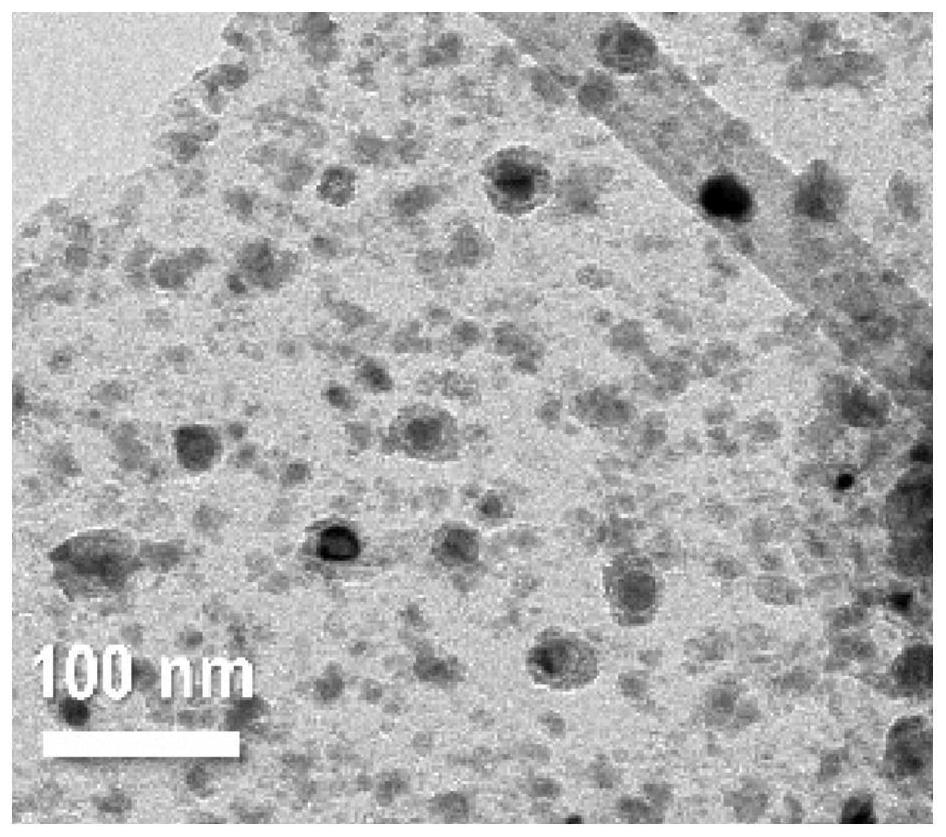

[0041] (3) Preparation of titanium cobalt oxide / porous graphene / porous carbon composite material:

[0042] A 2mol / L mixed solution of titanium salt and cobalt salt was prepared, the titanium salt was titanium tetrachloride, the cobalt salt was cobalt ace...

Embodiment 2

[0048] The present invention also provides a preparation method of the modified diaphragm for the lithium-sulfur battery, comprising the following steps:

[0049] (1) Preparation of porous carbon materials:

[0050] Clean 10 g of melamine sponge with absolute ethanol and deionized water, after drying, carbonize the melamine sponge at 500° C. for 6 hours under a nitrogen protective atmosphere, and obtain a carbon sponge after cooling;

[0051] (2) Preparation of porous graphene oxide:

[0052] Graphene oxide was ultrasonically dispersed in a 15M sodium hydroxide solution, and then refluxed at 100°C for 10 hours; the obtained samples were washed with absolute ethanol and deionized water, filtered three times, and then dried;

[0053] (3) Preparation of titanium cobalt oxide / porous graphene / porous carbon composite material:

[0054] A 2mol / L mixed solution of titanium salt and cobalt salt was prepared, the titanium salt was titanium tetrachloride, the cobalt salt was cobalt ace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com