Mesocarbon microbeads, graphite anode material, preparation methods thereof, and lithium ion battery

A technology of mesophase carbon microspheres and graphite negative electrodes, applied in the directions of graphite, battery electrodes, secondary batteries, etc., can solve the problems of low discharge capacity, high discharge capacity, poor rate performance, etc., and achieve high discharge capacity and graphitization degree. The effect of high and high fast charging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

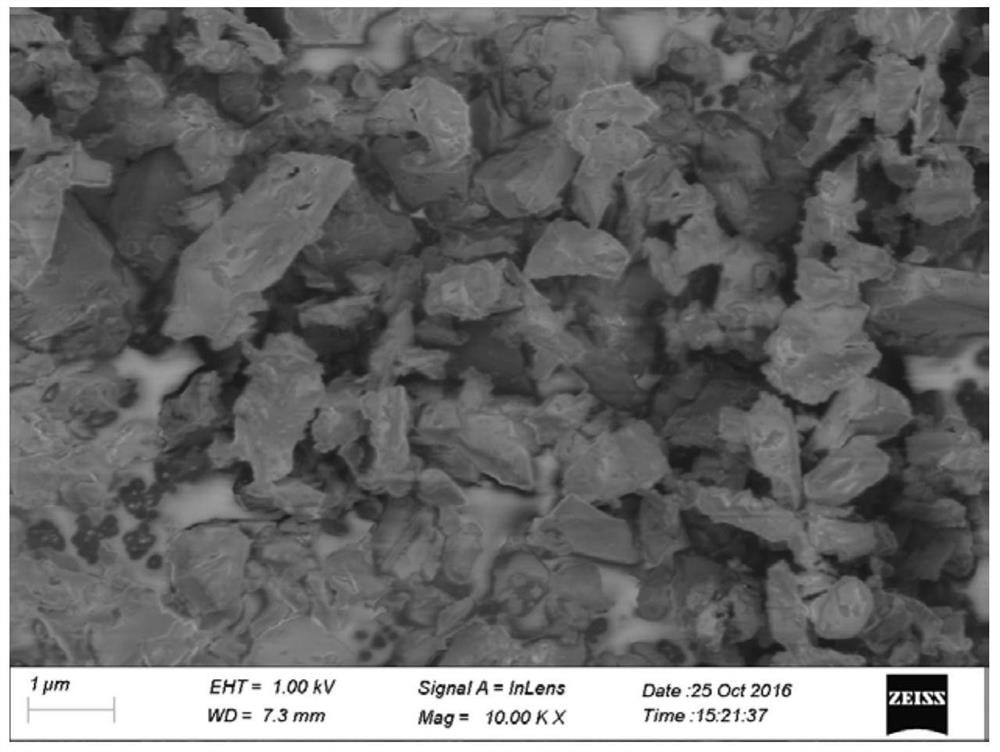

[0077] (1) SiC dry powder with a Dv50 particle size of 0.3 μm (SEM picture as shown in figure 1 Shown) is added in the washing oil solvent, and the mass fraction of silicon carbide in the solvent is 10%. Add hexamethyldisilamine (HMDS) according to 0.5% of the mass of silicon carbide dry powder, turn on high-speed stirring (line speed 15m / s) and heat up to 100°C for constant temperature treatment for 3 hours to obtain silicon carbide slurry.

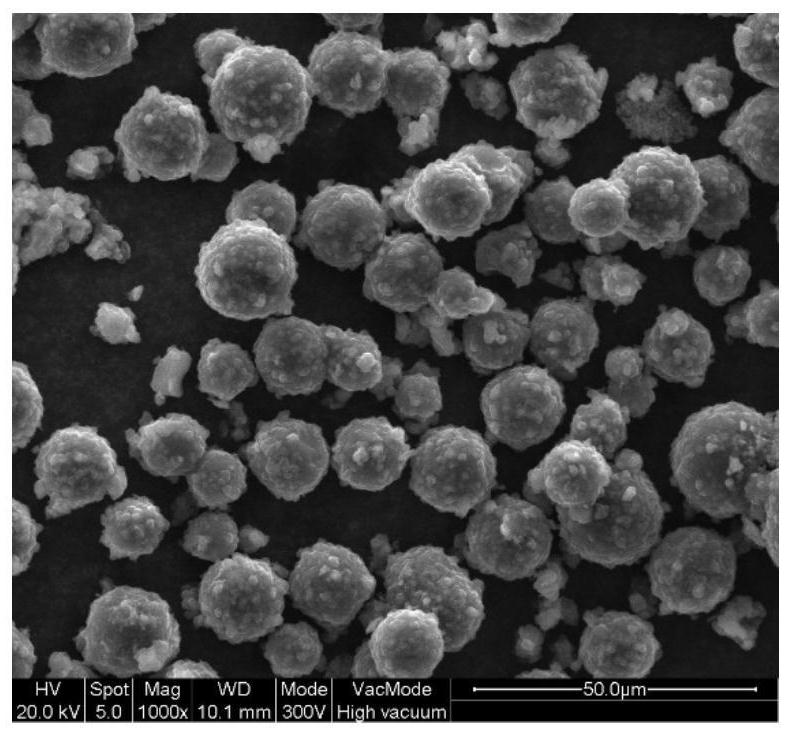

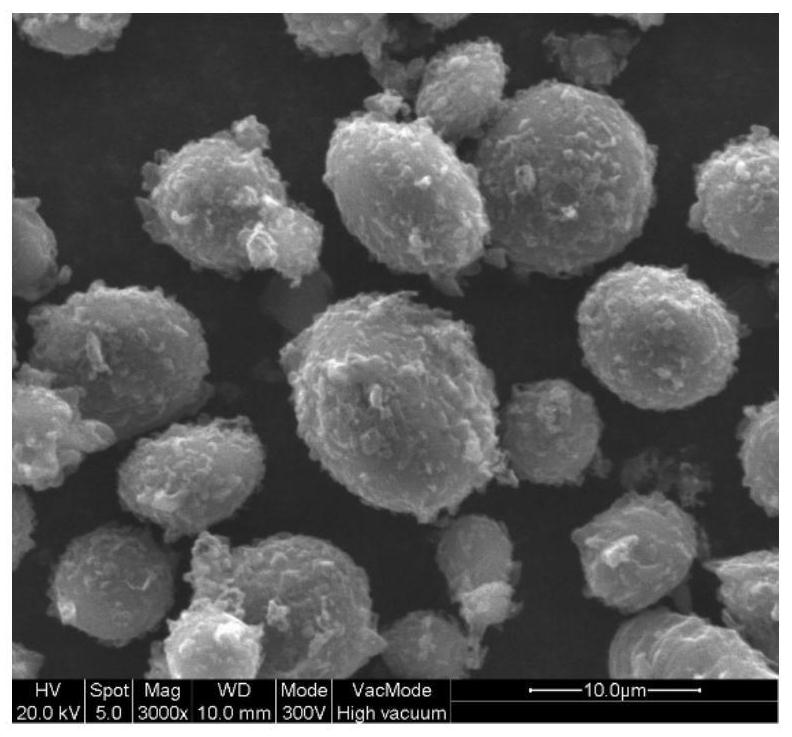

[0078] (2) Add the silicon carbide and refined coal pitch in step (1) to the molten refined pitch at a mass ratio of 0.005:1, and start stirring. The temperature of the system was raised to 440°C and kept constant for 8 hours. Turn off the heating, and when the temperature drops to 300°C, add toluene five times the weight of refined coal pitch to the reaction, filter while it is hot, and rinse with toluene of the same quality, and vacuum dry at 110°C for 24 hours to obtain mesophase carbon containing silicon carbide particles inside Mi...

Embodiment 2

[0082] The dispersant hexamethyldisilazane in step (1) in Example 1 was changed to trimethylchlorosilane, and other conditions and proportioning parameters remained unchanged to obtain the sample of Example 2.

Embodiment 3

[0084] Change the median Dv50 of silicon carbide in step (1) in Example 1 to 0.1 μm, and keep other conditions and proportioning parameters unchanged to obtain the sample of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com