Method for preparing porous biochar through ionic liquid modified waste biomass low-temperature pyrolysis, porous biochar and application of porous biochar

A technology for waste biomass, ionic liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

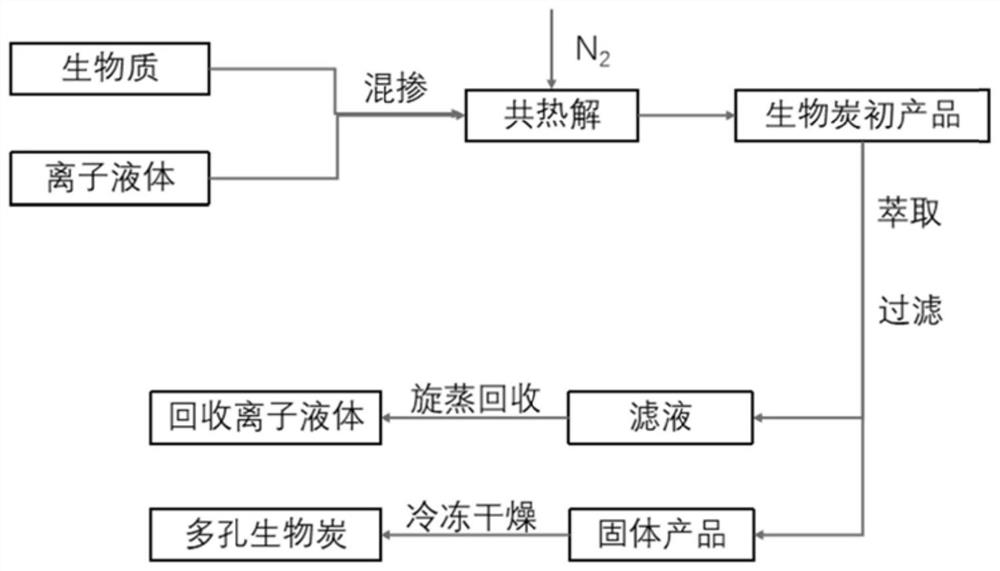

[0046] The method for preparing porous biochar by low-temperature pyrolysis of waste biomass modified by ionic liquid in this embodiment, such as figure 1 As shown, including steps such as blending, co-pyrolysis, extraction, filtration, freeze-drying, and rotary evaporation recovery, a biochar product with large specific surface area, high porosity, and more surface functional groups is finally obtained.

[0047] (1) Blending refers to heating the reactants to a temperature range of 20-30° C. higher than the melting point of the ionic liquid, so that the ionic liquid is in a molten state and fully mixed with the biomass.

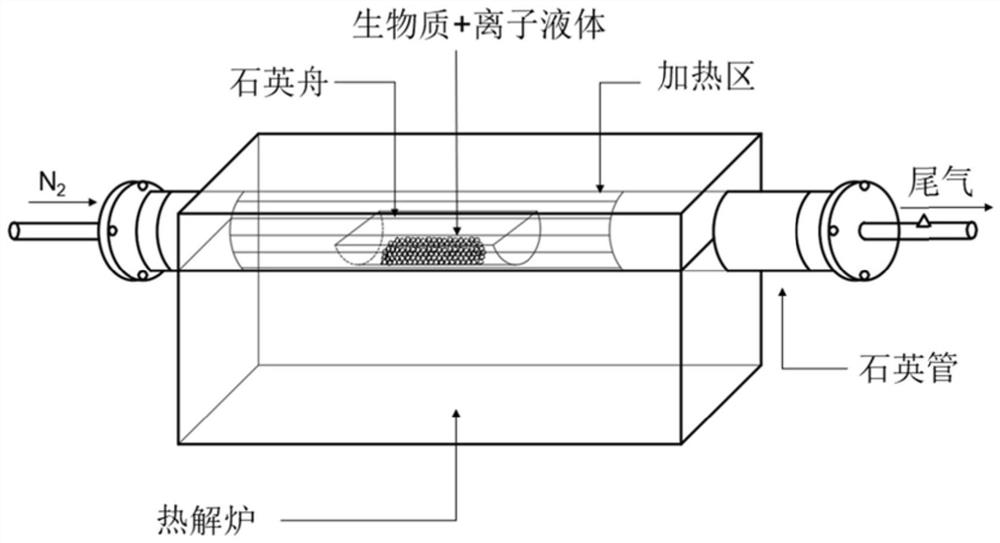

[0048] (2) In co-pyrolysis, a small high-temperature sintering tube furnace produced by Hefei Kejing Material Technology Co., Ltd., model OTF-1200X-S, was used. Put the uniformly mixed reactants in a quartz boat with a length of 10cm and a radius of 2cm. Place the quartz boat in the quartz tube of the tube furnace. The original air in the quartz tube starts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com