Inorganic mineral enhancer

An inorganic mineral and reinforcing agent technology, applied in the field of inorganic mineral reinforcing agent, can solve the problems of delayed hydration exothermic peak, early strength reduction, shrinkage deformation increase, etc., and achieves environmental protection, early strength improvement, hydration Heat release reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

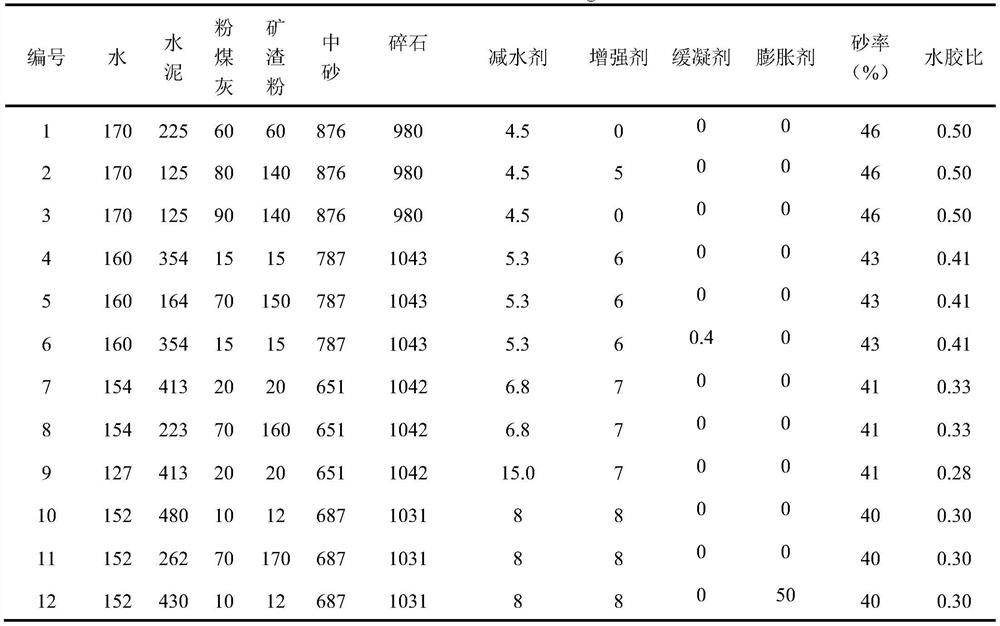

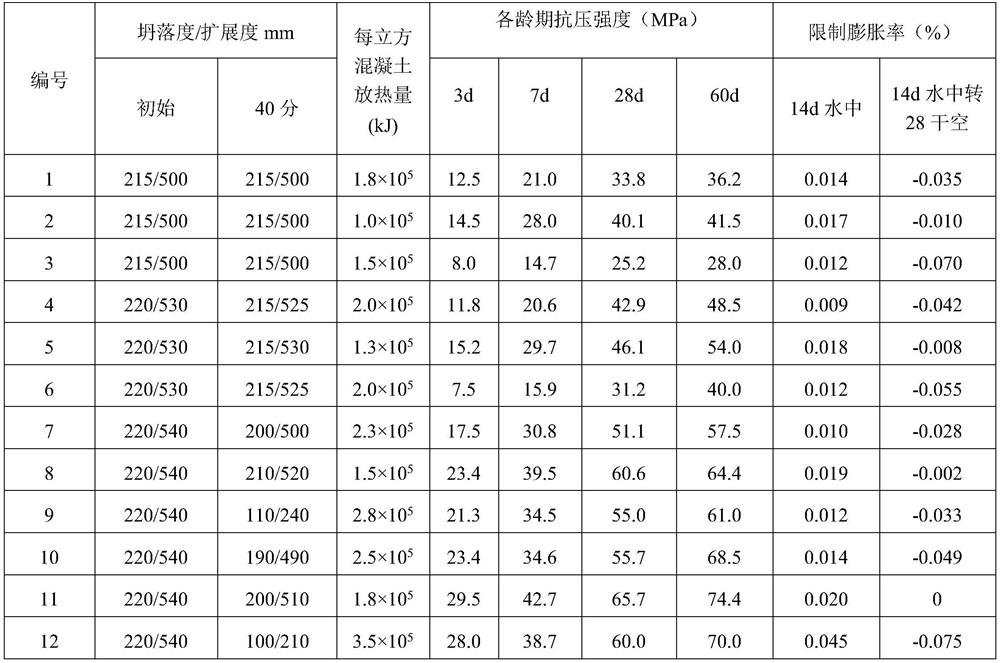

Embodiment 1

[0014] Example 1 The concrete components are as follows in parts by mass: 170 parts of water, 225 parts of cement, 60 parts of fly ash, 60 parts of slag powder, 876 parts of medium sand, 980 parts of gravel, 4.5 parts of water reducing agent, reinforcing agent 0 parts, retarder 0 parts, expansion agent 0 parts.

Embodiment 2

[0015] Example 2 The concrete components are as follows in parts by mass: 170 parts of water, 125 parts of cement, 80 parts of fly ash, 140 parts of slag powder, 876 parts of medium sand, 980 parts of gravel, 4.5 parts of water reducing agent, reinforcing agent 5 parts, retarder 0 parts, expansion agent 0 parts.

Embodiment 3

[0016] Example 3 The concrete components are as follows in parts by mass: 170 parts of water, 125 parts of cement, 90 parts of fly ash, 140 parts of slag powder, 876 parts of medium sand, 980 parts of gravel, 4.5 parts of water reducing agent, reinforcing agent 0 parts, retarder 0 parts, expansion agent 0 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com