Preparation method of sea pebble, sea sand, seawater and regenerated micro-powder concrete

A technology for regenerating micropowder and sea pebbles, which is applied in the field of preparation of regenerated micropowder concrete from sea pebble, sea sand and seawater, can solve the problems of limiting the application of recycled concrete, low concrete tensile strength, and large shrinkage of concrete, and achieves green sustainable development, The effect of promoting ecological and economic benefits, increasing tensile strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

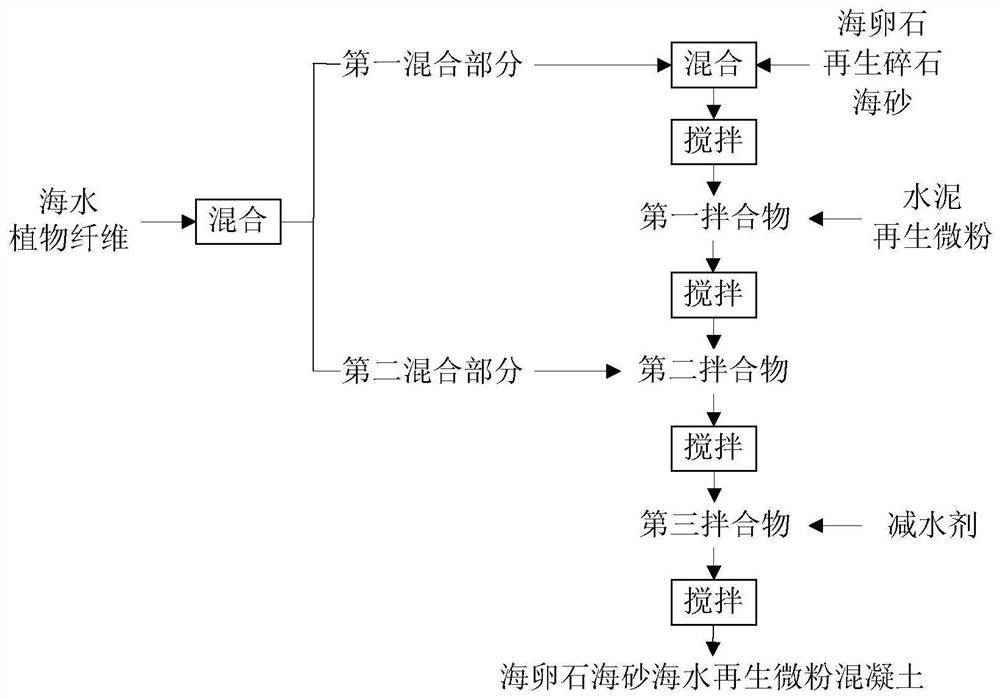

Method used

Image

Examples

Embodiment 1

[0069] Prepare sea pebble sea sand seawater recycled micropowder concrete sample 1#, by weight percentage, including the following components: cement 10.8%; recycled micropowder 2%; sea pebble 27.5%; recycled crushed stone 27.5%; sea sand 25%; %; plant fiber 1%; water reducing agent 0%. See Table 1 for specific ratios.

[0070] Among them, the cement is P.O.42.5 ordinary Portland cement; the recycled micropowder is the particles with a particle size of less than 75 μm and an activity index greater than 70% obtained after crushing, removing impurities, and grinding of waste concrete; sea pebbles are 5-25mm continuous graded sea Pebbles; recycled crushed stones are 5-25mm continuous graded recycled crushed stones obtained from waste concrete after crushing, impurity removal, and screening; sea sand is sea sand with a fineness modulus of 2.7; plant fibers are jute fibers with a length of 10 mm.

[0071] The plant fiber and seawater are evenly mixed according to the proportion to...

Embodiment 2

[0074] Prepare sea pebble sea sand seawater recycled micropowder concrete sample 2#, by weight percentage, including the following components: cement 9.8%; recycled micropowder 2%; sea pebble 27.5%; recycled crushed stone 27.5%; sea sand 25%; %; plant fiber 2%; water reducing agent 0%. See Table 1 for specific ratios.

[0075] Among them, the cement is P.O.42.5 ordinary Portland cement; the recycled micropowder is the particles with a particle size of less than 75 μm and an activity index greater than 70% obtained after crushing, removing impurities, and grinding of waste concrete; sea pebbles are 5-25mm continuous graded sea Pebbles; recycled crushed stones are 5-25mm continuous graded recycled crushed stones obtained from waste concrete after crushing, impurity removal, and screening; sea sand is sea sand with a fineness modulus of 2.7; plant fibers are jute fibers with a length of 10 mm.

[0076] The plant fiber and seawater are evenly mixed according to the proportion to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com