Spraying-free polybutylene terephthalate fiber-added composite material and preparation method thereof

A technology of polybutylene terephthalate and composite materials, which is applied in the field of spray-free polybutylene terephthalate plus fiber composite materials and its preparation, and can solve the problem of damaging the overall mechanical properties and temperature resistance of composite materials Performance, comprehensive mechanical properties and temperature resistance and chemical resistance discount, poor surface gloss of floating fibers on the surface, etc., to achieve the effect of improving the contact interface layer, excellent mechanical properties and temperature resistance, and high surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

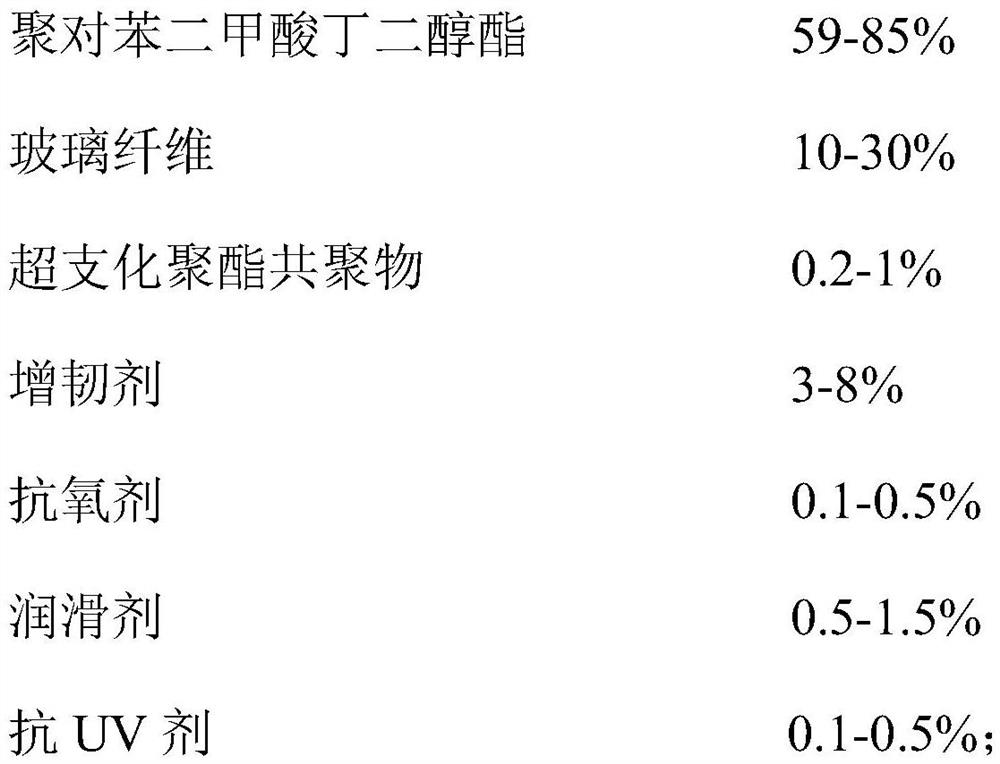

[0063] The present embodiment provides a spray-free polybutylene terephthalate fiber-reinforced composite material, which is prepared from the following components by weight percentage:

[0064]

[0065] The preparation method of the above-mentioned spray-free polybutylene terephthalate fiber-reinforced composite material is as follows:

[0066] The polybutylene terephthalate, hyperbranched polyester copolymer, toughener BF-E, antioxidant 1098, antioxidant S-9228, lubricant ST-LS100, lubricant OP wax and Anti-UV agent UV-234 is mixed, the mixed material is added to the twin-screw extruder from the main feeding port, and the glass fiber is added to the side feeding port of the twin-screw extruder, and melt blending , after extrusion, the spray-free polybutylene terephthalate fiber-added composite material is obtained; the process parameters of the twin-screw extruder are as follows: the temperature of the first zone is 220°C, the temperature of the second zone is 230°C, and ...

Embodiment 2

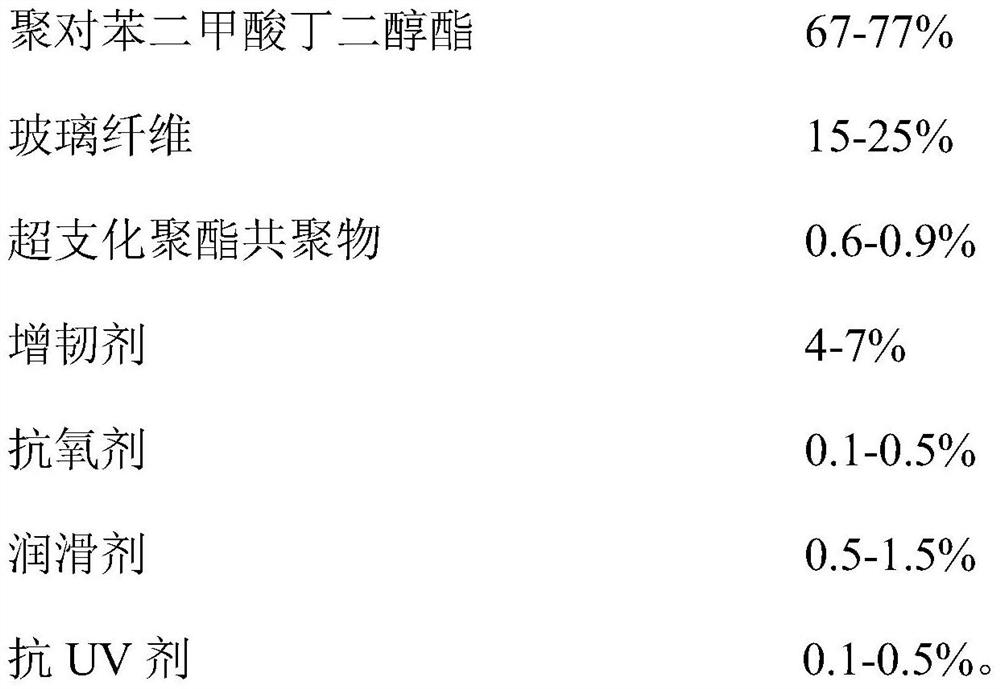

[0068] The present embodiment provides a spray-free polybutylene terephthalate fiber-reinforced composite material, which is prepared from the following components by weight percentage:

[0069]

[0070] The preparation method of the above-mentioned spray-free polybutylene terephthalate fiber-reinforced composite material is as follows:

[0071] The polybutylene terephthalate, hyperbranched polyester copolymer, toughener BF-E, antioxidant 1098, antioxidant S-9228, lubricant ST-LS100, lubricant OP wax and Anti-UV agent UV-234 is mixed, the mixed material is added to the twin-screw extruder from the main feeding port, and the glass fiber is added to the side feeding port of the twin-screw extruder, and melt blending , after extrusion, the spray-free polybutylene terephthalate fiber-added composite material is obtained; the process parameters of the twin-screw extruder are as follows: the temperature of the first zone is 220°C, the temperature of the second zone is 230°C, and ...

Embodiment 3

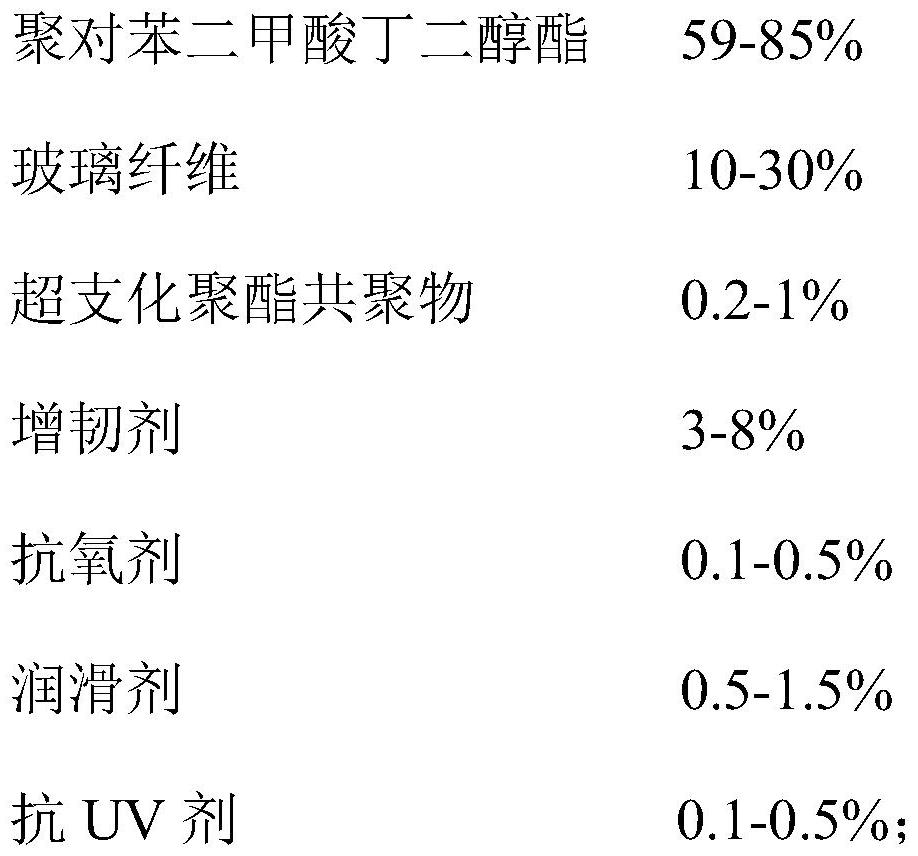

[0073] The present embodiment provides a spray-free polybutylene terephthalate fiber-reinforced composite material, which is prepared from the following components by weight percentage:

[0074]

[0075] The preparation method of the above-mentioned spray-free polybutylene terephthalate fiber-reinforced composite material is as follows:

[0076] The polybutylene terephthalate, hyperbranched polyester copolymer, toughener BF-E, antioxidant 1098, antioxidant S-9228, lubricant ST-LS100, lubricant OP wax and Anti-UV agent UV-234 is mixed, the mixed material is added to the twin-screw extruder from the main feeding port, and the glass fiber is added to the side feeding port of the twin-screw extruder, and melt blending , after extrusion, the spray-free polybutylene terephthalate fiber-added composite material is obtained; the process parameters of the twin-screw extruder are as follows: the temperature of the first zone is 220°C, the temperature of the second zone is 230°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com