Preparation method of halogen-free flame-retardant nylon filaments

A technology for flame-retardant nylon and filaments, which is applied in the manufacture of fire-resistant and flame-retardant filaments, rayon, and single-component polyamide rayon, and can solve the problems of high toxicity and low viscosity of flame-retardant nylon filaments. Achieve the effects of good dyeing uniformity and spinnability, simple process and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

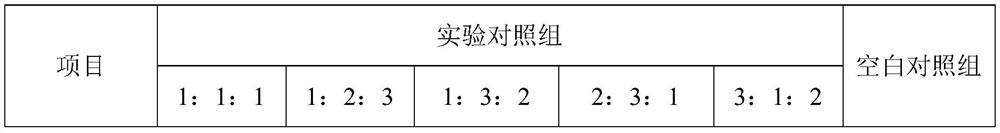

[0022] Preparation of halogen-free flame retardant masterbatch: Nylon 6 slices with a mass fraction of 55%, graphite-like carbon nitride with a mass fraction of 40% and a mass ratio of 1:3:2, and melamine polyphosphate coated with silane microcapsules , a compound of aluminum diethyl hypophosphite, a halogen-free flame retardant, a styrene-maleic anhydride compatibilizer with a mass fraction of 3%, and an antioxidant 1216 with a mass fraction of 2% were added to a high-efficiency dynamic mixer and mixed Evenly, after being fully mixed and uniform, the material is discharged into the feeding port of the twin-screw extruder, melted and extruded through the twin-screw extruder, cooled with a pull rod, and then dragged and pelletized. The temperature settings of each zone of the twin-screw extruder are respectively 210°C-210°C-220°C-220°C-225°C-230°C-230°C-230°C-235°C-235°C-230°C, the temperature of the cooling water is controlled at 60°C, and it is obtained by melt extrusion granu...

Embodiment 2

[0025] Preparation of halogen-free flame retardant masterbatch: Nylon 66 chips with a mass fraction of 60%, graphite-like carbon nitride with a mass fraction of 35% and a mass ratio of 1:3:2, and melamine polyphosphate coated with silane microcapsules , a compound of calcium diethyl hypophosphite, a halogen-free flame retardant, a styrene-maleic anhydride compatibilizer with a mass fraction of 2.5%, and an antioxidant 1010 with a mass fraction of 2.5% are added to a high-efficiency dynamic mixer and mixed Evenly, after being fully mixed and uniform, the material is discharged into the feeding port of the twin-screw extruder, melted and extruded through the twin-screw extruder, cooled with a pull rod, and then dragged and pelletized. The temperature settings of each zone of the twin-screw extruder are respectively 250°C-250°C-260°C-260°C-260°C-265°C-265°C-265°C-270°C-270°C-265°C, the cooling water temperature is controlled at 60°C, granulated by melt extrusion and cooled to obta...

Embodiment 3

[0028] Preparation of halogen-free flame retardant masterbatch: Nylon 56 slices with a mass fraction of 58%, graphite-like carbon nitride with a mass fraction of 38% and a mass ratio of 1:3:2, and melamine polyphosphate coated with silane microcapsules , a compound of magnesium diethyl hypophosphite halogen-free flame retardant, a styrene-maleic anhydride compatibilizer with a mass fraction of 2%, and an antioxidant 1330 with a mass fraction of 2% were added to a high-efficiency dynamic mixer and mixed Evenly, after being fully mixed and uniform, the material is discharged into the feeding port of the twin-screw extruder, melted and extruded through the twin-screw extruder, cooled with a pull rod, and then dragged and pelletized. The temperature settings of each zone of the twin-screw extruder are respectively 245°C-245°C-250°C-250°C-250°C-260°C-260°C-260°C-265°C-265°C-260°C, the cooling water temperature is controlled at 60°C, granulated by melt extrusion and cooled to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com