High-temperature-resistant and high-pressure-resistant energetic material rod structure and application thereof

A high temperature resistant, material rod technology, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of reducing the cementation position, reducing the success rate of controllable shock wave operation, etc., reducing the cementing position and widening the application performance, improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

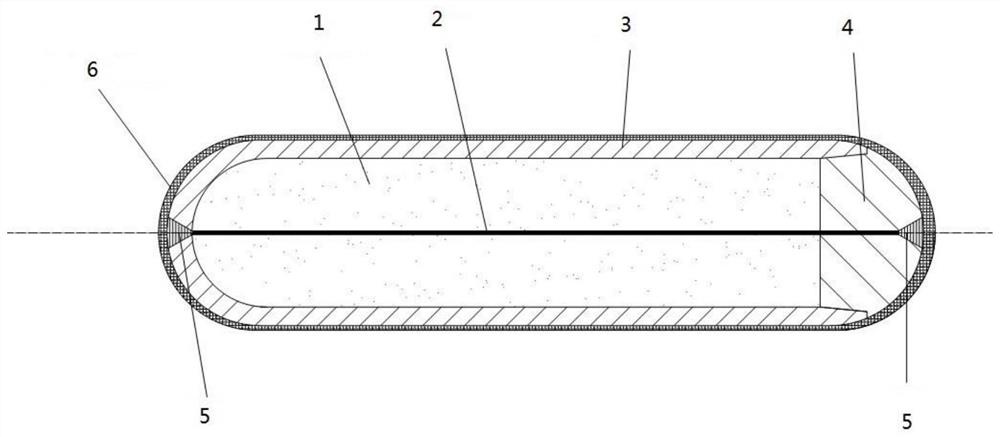

[0021] A high temperature and high pressure resistant energetic material rod structure, including a high temperature resistant shell, a powdery energetic material 1, a metal wire 2, a fixing member 5 and a pressure-resistant coating 6,

[0022] The high temperature resistant shell includes a U-shaped pipe body 3 and a plug 4. The U-shaped pipe body 3 adopts a hollow cylindrical structure with one end open and the other end closed. One end of the plug 4 is a hemispherical compression structure, and the other end of the plug 4 is It is a cylindrical structure matching the open end of the U-shaped pipe body 3. The U-shaped pipe body 3 is connected to the plug 4 by bonding, and the closed end of the U-shaped pipe body 3 and the center of the plug 4 There is a fixing hole for fixing the metal wire 2 at the center. The first and last ends of the metal wire 2 are respectively fixed in the fixing hole by the fixing piece 5. The energetic material 1 is coated with a pressure-resistant ...

Embodiment 2

[0024] On the basis of the first embodiment, the U-shaped pipe body 3 and the plug 4 are made of aluminum oxide high-temperature ceramic material, and the high-temperature ceramic material has a temperature resistance of 150°C.

[0025] The metal wire 2 is made of metal tungsten, metal tantalum or metal copper, and the diameter of the metal wire 2 is 300-500 μm.

[0026] The powdery energetic material 1 includes strong oxidant, nitrocellulose, nitrate, etc., the particle size of the powdery energetic material 1 is 20-200 μm, and the powdery energetic material 1 is mixed by a wet method to ensure dispersion and optimal filling density.

[0027] The pressure-resistant coating 6 adopts multi-walled carbon nanotube coating.

[0028] During assembly, the first end of the metal wire 2 is first riveted to the fixing hole in the center of the hemispherical closed end of the U-shaped tube body 3, and reinforced with a sealant, and then the powdery energetic material 1 is filled accord...

Embodiment 3

[0030] On the basis of Example 2, an energetic material rod structure resistant to high temperature and high pressure is applied in a controllable shock wave device under high temperature and high pressure conditions. The energetic material rod structure needs to be driven by a driving source with a pulse power of more than 800J.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com