Method for preparing instant shrimp meat by microwave and hot air combined drying

A technology of combined drying and microwave hot air, applied in the direction of food drying, drying preservation of meat/fish, food ingredients, etc. Reduce the effect of coking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Choose fresh or thawed prawns as raw materials, wash them, remove the shells, steam for 10 minutes, and then drain;

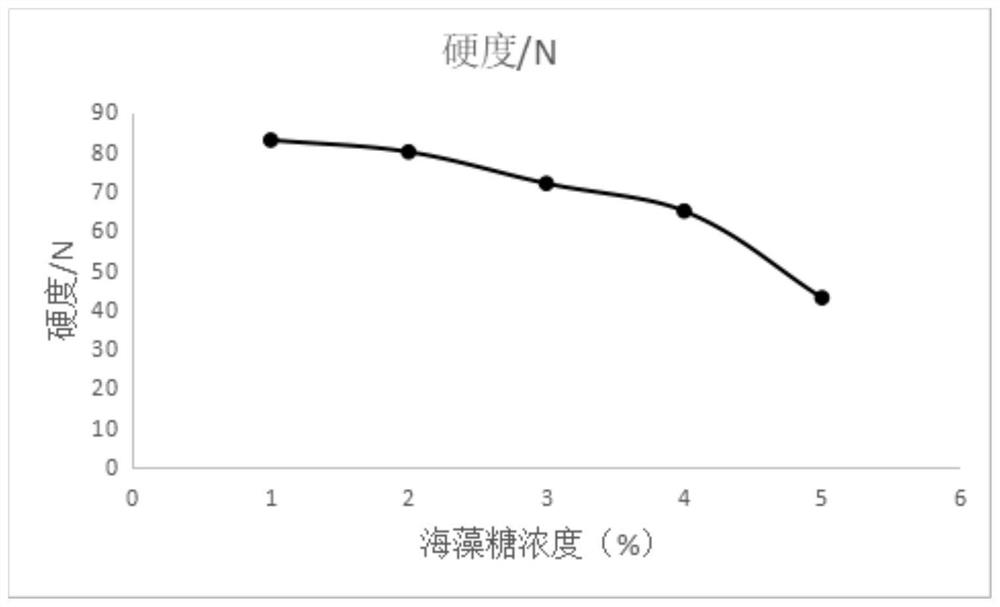

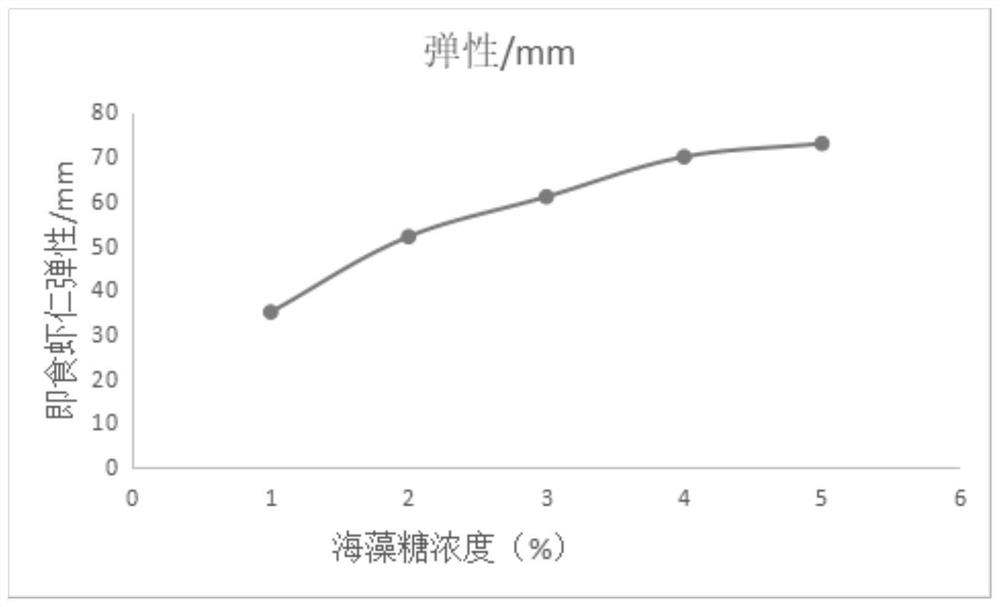

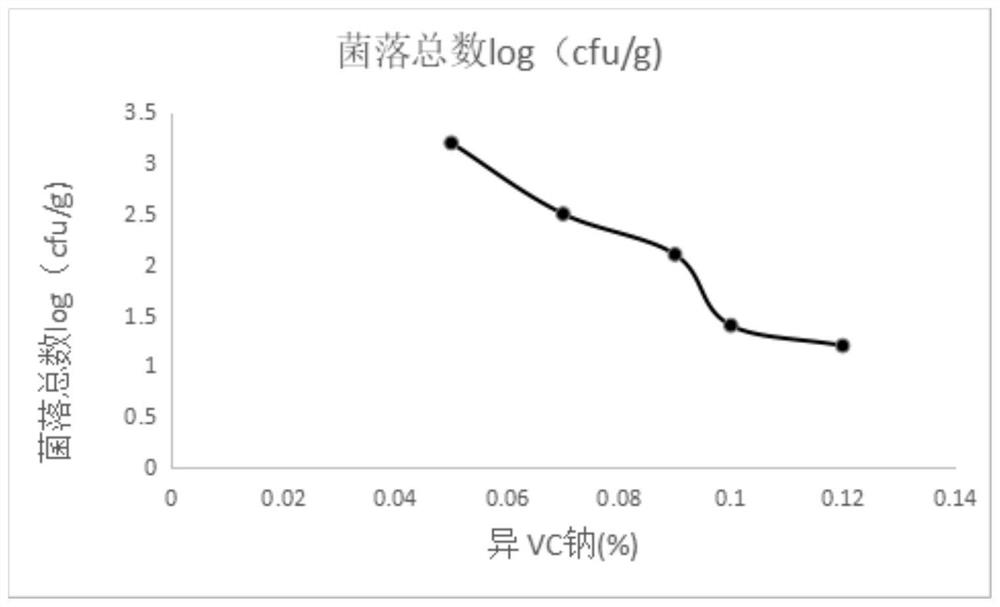

[0027] (2) Put the drained shrimps in the seasoning liquid and marinate them for 20 minutes. The weight ratio of the drained shrimps to the seasoning liquid is 1:1-3:1. The composition of the seasoning liquid is based on the weight of the drained shrimps, including: 0.1% monosodium glutamate, 8% tomato sauce, 1% trehalose, 10% corn starch, 0.05% sodium iso-VC, and the balance is water;

[0028] (3) Microwave drying and hot air drying are performed on the pickled shrimps in sequence: first, dry them with a microwave power of 200W for 5 minutes, and then dry the shrimps after microwave drying at a hot air temperature of 60°C for 5 hours until the moisture content is lower than 5%. dried shrimp;

[0029] (4) Combine the dried dried shrimp with vacuum packaging, and sterilize to obtain a kind of instant dried shrimp with a sweet and sour tomato flavor. ...

Embodiment 2

[0031] (1) Select fresh or thawed prawns as raw materials, wash them, remove the shells, steam for 30 minutes, and then drain;

[0032] (2) Put the drained shrimps in the seasoning solution and marinate them for 30 minutes to taste. The weight ratio of the drained shrimps to the seasoning solution is 1:1 to 3:1. The composition of the seasoning solution is based on the weight of the drained shrimps, including: 0.2% monosodium glutamate, 4% tomato sauce, 2% trehalose, 8% corn starch, 0.07% sodium iso-VC, and the balance is water;

[0033] (3) Microwave drying and hot air drying are performed on the pickled shrimps in sequence: first, dry them with a microwave power of 400W for 3 minutes, and then dry the shrimps after microwave drying at a hot air temperature of 70°C for 4 hours until the moisture content is lower than 5%. dried shrimp;

[0034] (4) Combine the dried dried shrimp with vacuum packaging, and sterilize to obtain a kind of instant dried shrimp with a sweet and sou...

Embodiment 3

[0036] (1) Choose fresh or thawed prawns as raw materials, wash them, remove the shells, steam for 15 minutes, and then drain;

[0037] (2) Put the drained shrimps in the seasoning liquid and marinate them for 60 minutes. The weight ratio of the drained shrimps to the seasoning liquid is 1:1-3:1. The composition of the seasoning liquid is based on the weight of the drained shrimps, including: 0.4% monosodium glutamate, 5% tomato sauce, 3% trehalose, 7% corn starch, 0.06% sodium isoVC, and the balance is water;

[0038] (3) Microwave drying and hot air drying are performed on the pickled shrimps in sequence: first, dry them with a microwave power of 500W for 3 minutes, and then dry the shrimps after microwave drying at a hot air temperature of 75°C for 3.5 hours until the water content is lower than 5%. get dried shrimp;

[0039] (4) Combine the dried dried shrimp with vacuum packaging, and sterilize to obtain a kind of instant dried shrimp with a sweet and sour tomato flavor....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com