Preparation method and application of nickel-doped pyrrhotite FeS nanoparticles

A nanoparticle and pyrrhotite technology, applied in chemical instruments and methods, physical/chemical process catalysts, structural parts, etc., can solve the problems of increasing synthesis cost and time, and achieve controllable shape, simple operation, and size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

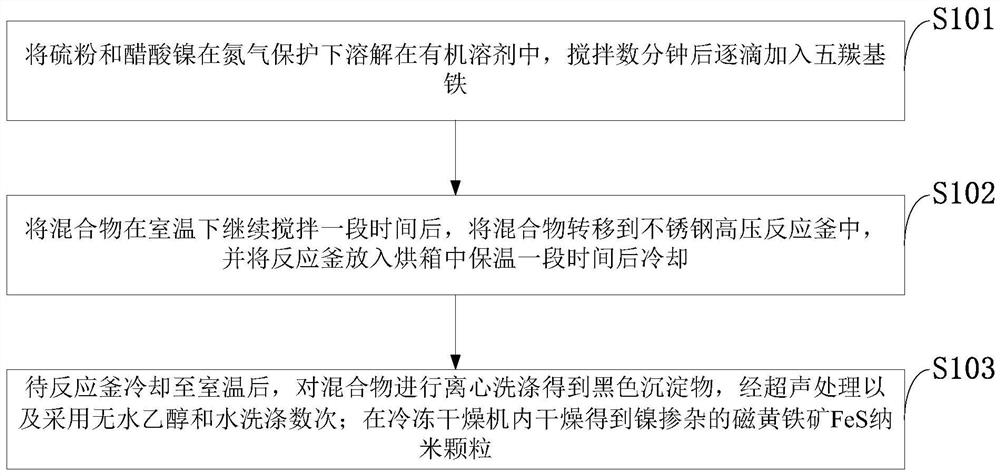

[0035] Such as figure 1 As shown, the preparation method of the nickel-doped pyrrhotite FeS nanoparticles provided by the invention comprises the following steps:

[0036] S101: Dissolving sulfur powder and nickel acetate in an organic solvent under nitrogen protection, stirring for several minutes, adding iron pentacarbonyl dropwise;

[0037] S102: After continuing to stir the mixture at room temperature for a period of time, the mixture is transferred to a stainless steel high-pressure reactor, and the reactor is placed in an oven to keep warm for a period of time and then cooled;

[0038] S103: After the reactor was cooled to room temperature, the mixture was centrifuged and washed to obtain a black precipitate, which was ultrasonically treated and washed several times with absolute ethanol and water; dried in a freeze dryer to obtain nickel-doped pyrrhotite FeS nanoparticles.

[0039] The preparation method of nickel-doped FeS nanoparticles provided in the embodiments of t...

Embodiment 1

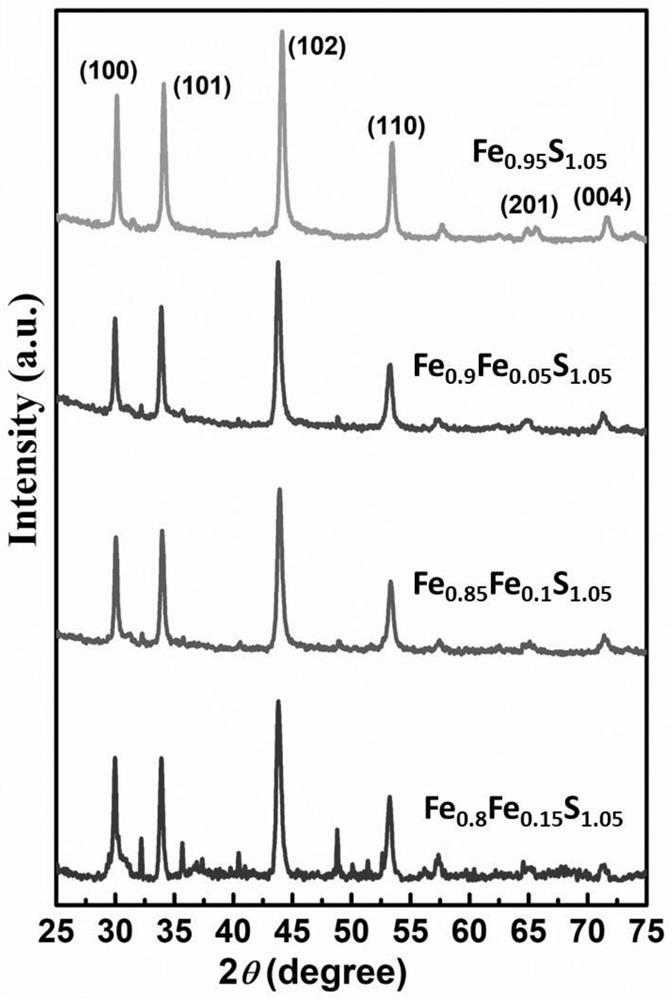

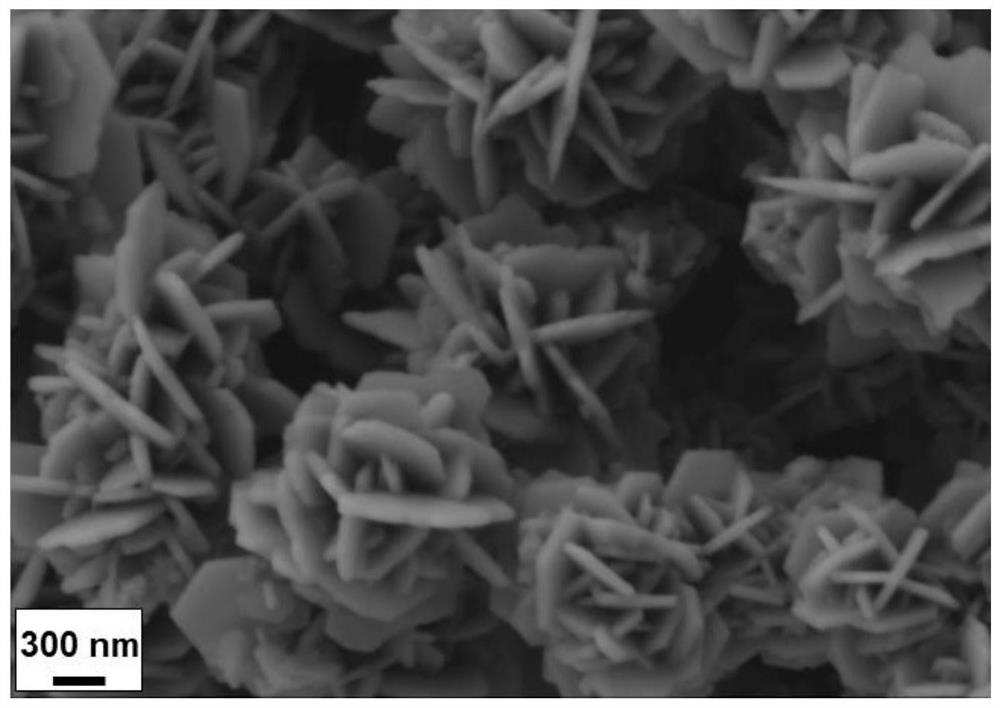

[0050] The preparation method of the nickel-doped FeS nanoparticle provided by the embodiment of the present invention comprises the following steps: firstly, 0.33 g of sublimed sulfur powder is dissolved in 35 mL of organic solvent with 40 mg; 80 mg; 160 mg of nickel acetate under nitrogen protection, And stir well. Then, 1 mL of iron pentacarbonyl was added dropwise under nitrogen protection. Then, the mixture was magnetically stirred rapidly at room temperature for 20 min, and then the mixture was transferred to a stainless steel autoclave, and the autoclave was placed in an oven at 210 ° C. Keep it for 16 hours; finally, after the temperature of the autoclave is cooled to room temperature, the mixture is centrifuged and washed to obtain a black precipitate. The above black precipitate is ultrasonically dispersed, washed alternately with absolute ethanol and water several times, and finally collected by centrifugation. , and dried in a vacuum freeze dryer for 2 hours to obt...

Embodiment 2

[0052] The preparation method of the nickel-doped FeS nanoparticle that the example of the present invention provides comprises the following steps: first the sublimation sulfur powder of 0.5g is respectively mixed with 40mg under nitrogen protection; 80mg; 160mg of nickel acetate is dissolved in 35mL organic solvent, and Stir well. Then, 1 mL of iron pentacarbonyl was added dropwise under nitrogen protection. Then, the mixture was magnetically stirred rapidly at room temperature for 20 min, and then the mixture was transferred to a stainless steel autoclave, and the autoclave was placed in an oven at 210 ° C. Keep it for 16 hours; finally, after the temperature of the autoclave is cooled to room temperature, the mixture is centrifuged and washed to obtain a black precipitate. The above black precipitate is ultrasonically dispersed, washed alternately with absolute ethanol and water several times, and finally collected by centrifugation. , and dried in a vacuum freeze dryer fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com