Kidney bean bioactive peptide and application thereof to preparation of uric acid reducing drugs

A bioactive peptide and kidney bean technology, applied in the field of kidney bean bioactive peptides and its application in the preparation of uric acid-lowering drugs, can solve the problems of no relevant reports on uric acid-lowering activity, achieve high product yield and purity, and high degree of hydrolysis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the extraction of kidney bean protein

[0038] (1) Kidney beans soaked overnight, peeled, dried at 55°C, and ground into powder for later use.

[0039] (2) Alkaline extraction: Take 40 g of kidney bean powder in a beaker, add 1 L of deionized water, and extract for 2 hours at a temperature of 60° C. and a pH of 10.

[0040] (3) Acid precipitation: centrifuge at 3800r / min for 20min, adjust the pH of the supernatant to 4.3 with 1mol / L HCl, centrifuge after standing for a certain period of time, and freeze-dry the precipitate to obtain kidney bean protein.

Embodiment 2

[0041] Embodiment 2: screening of enzyme

[0042] (1) Take 3g of kidney bean protein, add 100ml of deionized water, and heat in a water bath for 30min.

[0043] (2) Add 1mol / L NaOH to adjust to the optimum pH value of each enzyme, add protease at the optimum temperature of each enzyme, and record the volume consumption of NaOH during the hydrolysis process.

[0044] (3) After 3 hours of enzymatic hydrolysis, remove the enzyme for 10 minutes, cool to room temperature, and centrifuge at a speed of 8000 rpm / min for 20 minutes. The supernatant is the enzymatic hydrolyzate of kidney bean protein, and freeze-dried for later use.

[0045] (4) Dissolve the freeze-dried kidney bean protein hydrolyzate, measure the xanthine oxidase inhibition rate of the kidney bean protein hydrolyzate under the action of different enzymes, and compare the effects of each enzyme on the uric acid-lowering activity of kidney bean protein.

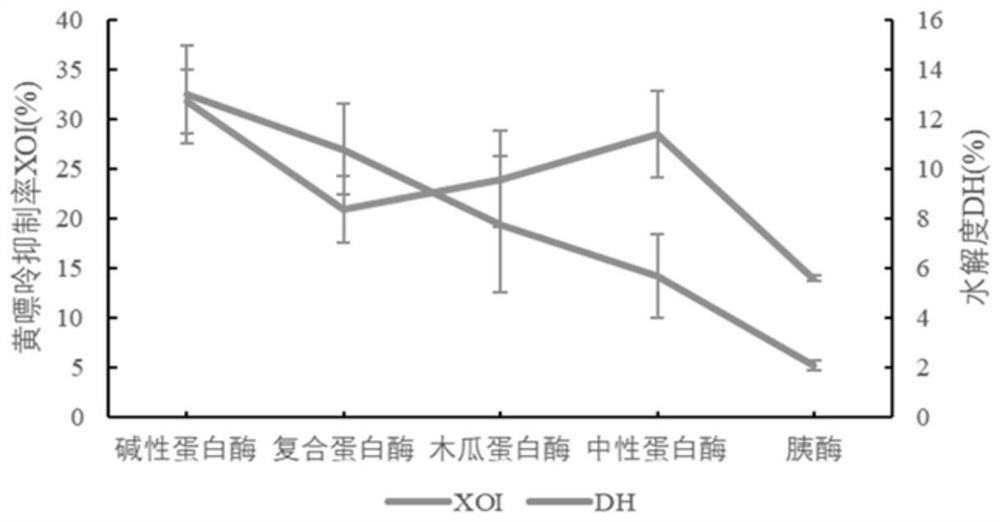

[0046] Such as figure 1 As shown, from the hydrolysis degree, t...

Embodiment 3

[0047] Example 3: Single factor experiment for the preparation of kidney bean uric acid peptide

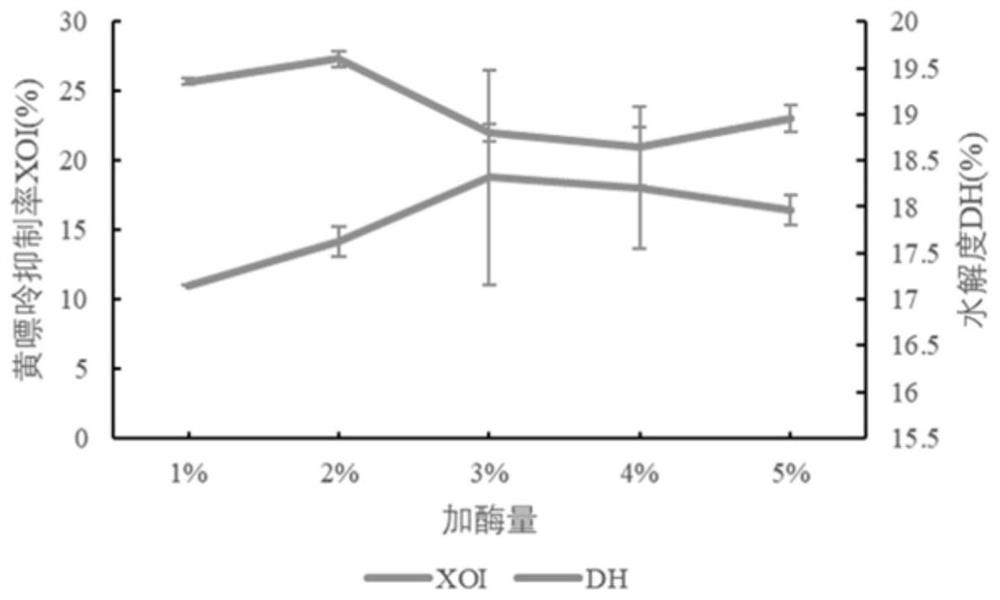

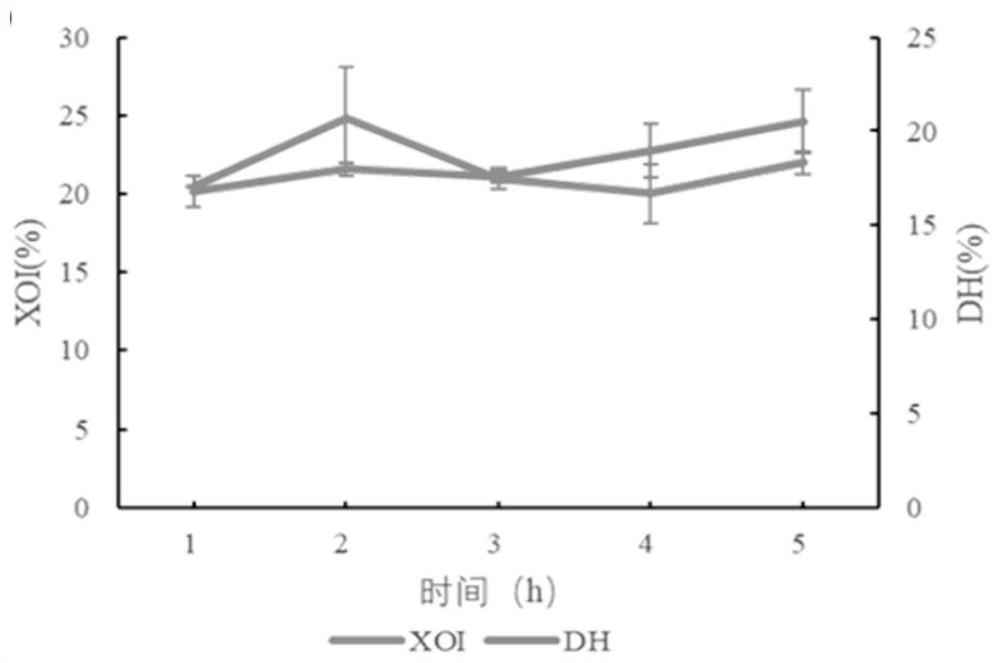

[0048] After the optimal enzyme was determined, the effects of different substrate concentrations (w / w), different enzyme additions (w / w), and different enzymatic hydrolysis times on the degree of hydrolysis of kidney bean protein and the XO inhibitory activity of its enzymatic hydrolyzate were investigated through single factor experiments. Impact. The specific implementation is as follows:

[0049] (1) Add kidney bean protein to deionized water to form a protein solution with a certain concentration, and heat for 30 minutes to break the primary structure of the protein.

[0050] (2) Adjust the pH of the kidney bean protein solution to 8.0 at a temperature of 55°C, add alkaline protease according to different enzyme-to-substrate ratios, add 1mol / L NaOH during the enzymolysis process to keep the enzymolysis pH at 8.0, and record the hydrolysis process The volume of NaOH consumed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com