Quantum dot light-emitting diode and its preparation method

A quantum dot light-emitting and diode technology, which is applied in the manufacture of semiconductor/solid-state devices, organic semiconductor devices, electric solid-state devices, etc., can solve the problems of uneven light-emitting layer of quantum dots, interface defects of electron transport layer, affecting the light-emitting performance of devices, etc. Achieve the effect of suppressing fluorescence quenching, reducing interface defects and improving coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

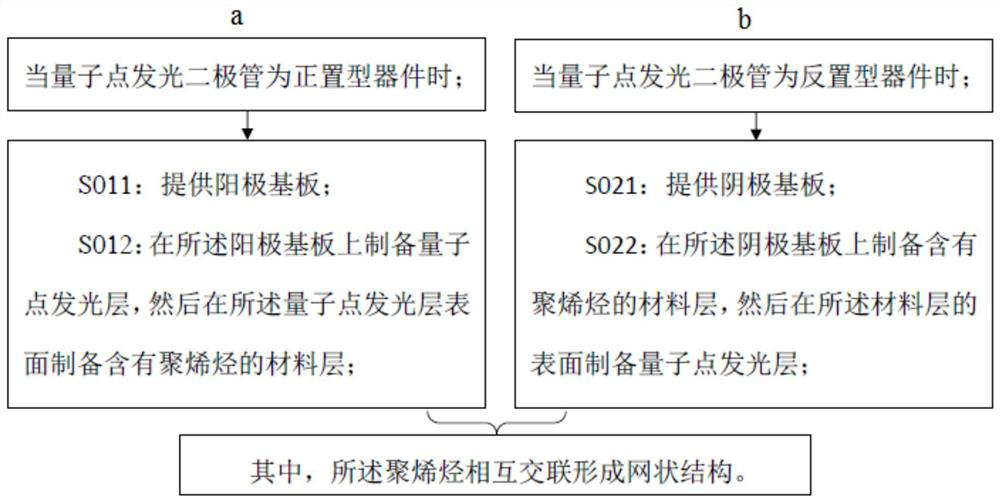

[0029] On the other hand, the embodiment of the present invention also provides a method for preparing a quantum dot light-emitting diode, including the following steps:

[0030] Such as figure 1 As shown in a, when the quantum dot light-emitting diode is a positive device,

[0031] S011: Provide anode substrate;

[0032] S012: preparing a quantum dot luminescent layer on the anode substrate, and then preparing a material layer containing polyolefin on the surface of the quantum dot luminescent layer;

[0033] or, as in figure 1 As shown in b, when the quantum dot light-emitting diode is an inverted device,

[0034] S021: Provide cathode substrate;

[0035] S022: Prepare a material layer containing polyolefin on the cathode substrate, and then prepare a quantum dot light-emitting layer on the surface of the material layer;

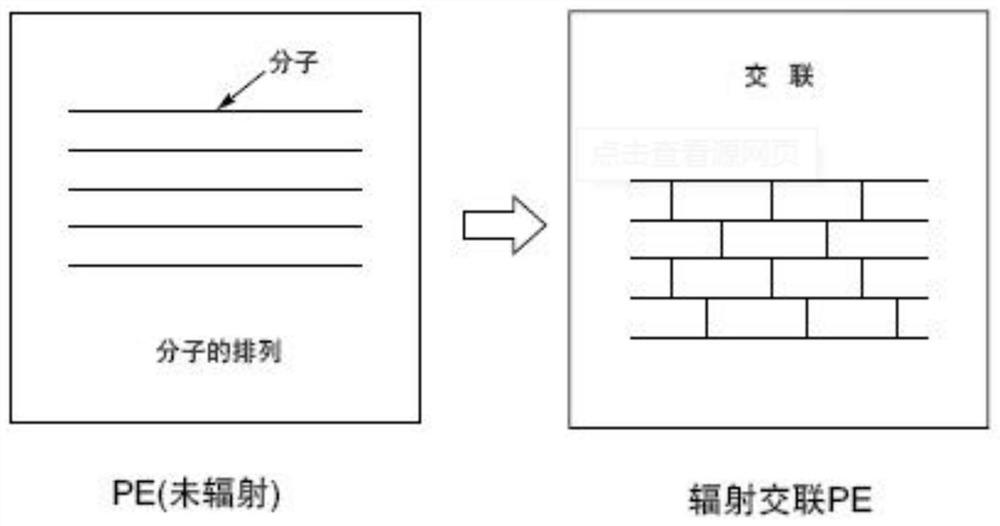

[0036] Wherein, the polyolefins are cross-linked with each other to form a network structure.

[0037] In the preparation method of the quantum dot ...

Embodiment 1

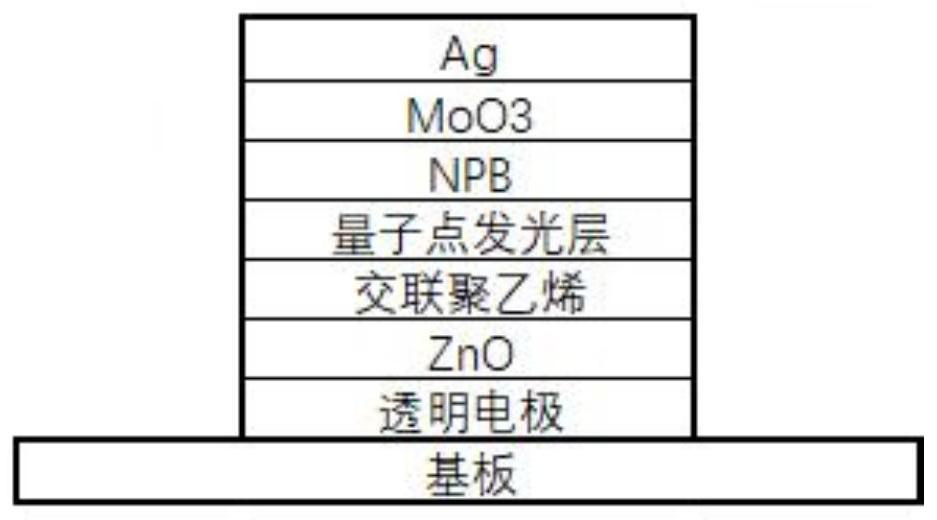

[0067] A kind of QLED device, its structure is as image 3 As shown, it includes from bottom to top: substrate, transparent electrode (cathode), ZnO electron transport layer, cross-linked polyethylene layer, quantum dot light-emitting layer, NPB hole transport layer, MoO 3 hole injection layer and Ag anode.

[0068] The preparation steps of the device are as follows:

[0069] First, the patterned ITO cathode substrate was placed in acetone, washing solution, deionized water and isopropanol in sequence for ultrasonic cleaning, and each step of ultrasonic cleaning lasted for about 15 minutes. After the ultrasound is completed, place the ITO in a clean oven to dry for later use.

[0070] After the ITO cathode substrate was dried, the ITO surface was treated with UV-ozone for 5 minutes to further remove the organic matter attached to the ITO surface and improve the work function of ITO.

[0071] Then, place the ITO cathode substrate processed in the previous step in a nitrogen ...

Embodiment 2

[0078] A kind of QLED device, its structure is as Figure 4 As shown, it includes from bottom to top: substrate, transparent electrode (cathode), ZnO electron transport layer, cross-linked polyethylene layer, quantum dot light-emitting layer, TPD hole transport layer, WO 3 Hole injection layer and Al anode.

[0079] The preparation steps of the device are as follows:

[0080]First, the patterned ITO cathode substrate was placed in acetone, washing solution, deionized water and isopropanol in sequence for ultrasonic cleaning, and each step of ultrasonic cleaning lasted for about 15 minutes. After the ultrasound is completed, place the ITO in a clean oven to dry for later use.

[0081] After the ITO substrate was dried, the ITO surface was treated with UV-ozone for 5 minutes to further remove the organic matter attached to the ITO surface and improve the work function of ITO.

[0082] Then, place the ITO cathode substrate processed in the previous step in a nitrogen atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com