Method for directionally arranging halloysite nanotubes on large scale

A technology of halloysite nanotubes and directional alignment, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of not having large-scale orientation, achieve good modification effect, simple purification process, and improve dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

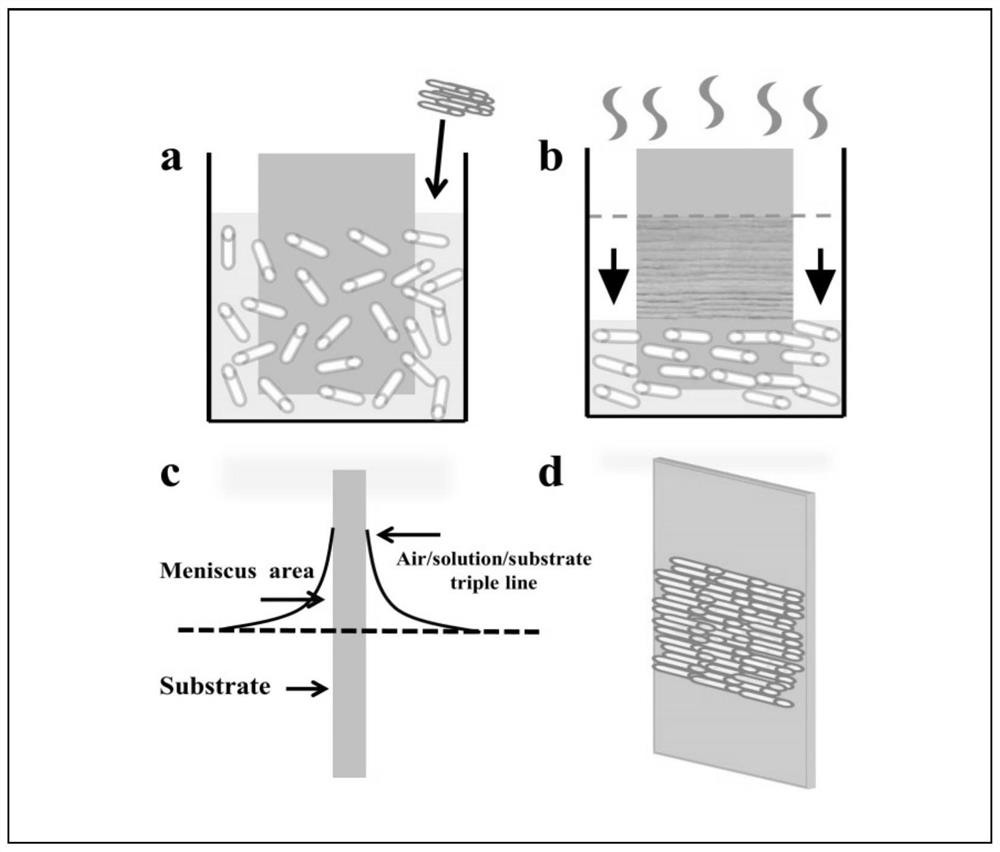

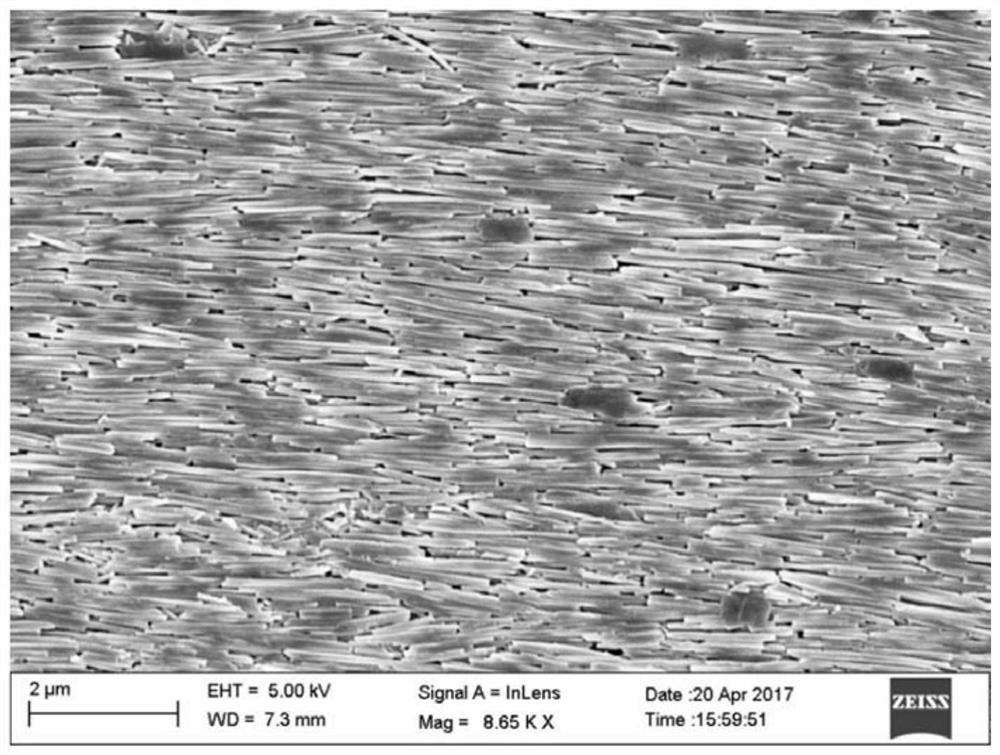

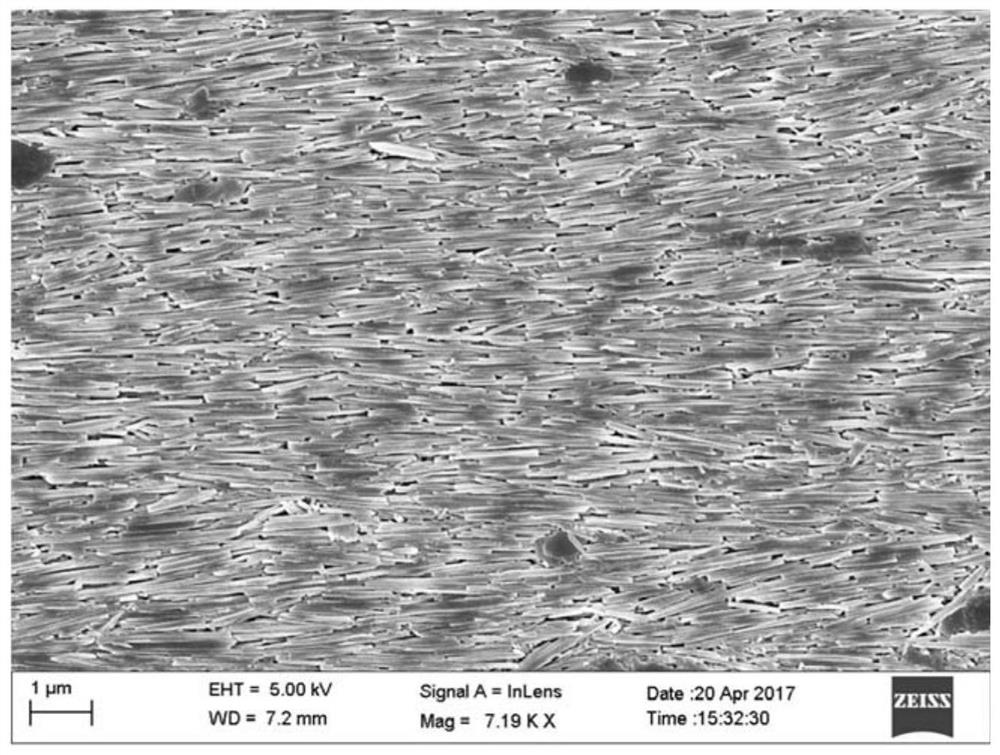

Method used

Image

Examples

Embodiment 1

[0056] (1) select the halloysite nanotube of length 800-1000nm, tube inner diameter 20-30nm and tube outer diameter 50-70nm as raw material;

[0057] (2) Disperse 10g halloysite nanotubes in 1000mL deionized water and stir for 1h, let it stand for 10min, take the supernatant, obtain pure halloysite nanotubes by ultrasonication, centrifugation and drying, wherein ultrasonication is 30min, and the ultrasonic frequency is 25KHz;

[0058] (3) Get dried halloysite nanotubes 2g and sodium hexametaphosphate 2g and add them into 200ml deionized water respectively, after stirring at room temperature for 24h, let stand for 3h to precipitate aggregates and impurities, collect the supernatant, centrifuge and wash for 3- After drying for 4 times, the modified halloysite nanotubes are obtained;

[0059] (4) Disperse 300 mg of modified halloysite nanotubes in 30 mL of solution (water: 98%, ethanol: 2%), and ultrasonicate for 30 minutes at an ultrasonic frequency of 25 KHz to obtain a disper...

Embodiment 2

[0063] (1) select the halloysite nanotube of length 800-1000nm, tube inner diameter 20-30nm and tube outer diameter 50-70nm as raw material;

[0064] (2) Disperse 10g halloysite nanotubes in 1000mL deionized water and stir for 1h, let it stand for 10min, take the supernatant, obtain pure halloysite nanotubes by ultrasonication, centrifugation and drying, wherein ultrasonication is 20min, and the ultrasonic frequency is 35KHz;

[0065] (3) Add 2 g of dried halloysite nanotubes and 1 g of sodium hexametaphosphate into 200 ml deionized water, stir at room temperature for 20 h, let stand for 1 h to precipitate aggregates and impurities, collect the supernatant, centrifuge and wash for 3- After drying for 4 times, the modified halloysite nanotubes are obtained;

[0066] (4) Disperse 300 mg of modified halloysite nanotubes in 30 mL of solution (water: 98%, ethanol: 2%), and ultrasonicate for 20 minutes at a frequency of 35 KHz to obtain a dispersion;

[0067] (5) Adjust the pH of ...

Embodiment 3

[0070] (1) select the halloysite nanotube of length 800-1000nm, tube inner diameter 20-30nm and tube outer diameter 50-70nm as raw material;

[0071] (2) Disperse 10g halloysite nanotubes in 1000mL deionized water and stir for 1h, let it stand for 10min, take the supernatant, obtain pure halloysite nanotubes by ultrasonication, centrifugation and drying, wherein ultrasonication is 40min, and the ultrasonic frequency is 30KHz;

[0072] (3) Get dried halloysite nanotubes 2g and sodium hexametaphosphate 5g and add them into 200ml deionized water, after stirring at room temperature for 26h, let stand for 4h to precipitate aggregates and impurities, collect the supernatant, centrifuge and wash for 3- After drying for 4 times, the modified halloysite nanotubes are obtained;

[0073] (4) Disperse 300 mg of modified halloysite nanotubes in 30 mL of solution (water: 98%, ethanol: 2%), and ultrasonicate for 40 min at a frequency of 30 KHz to obtain a dispersion;

[0074] (5) Adjust th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com